Touch sensor and production method thereof, and touch panel

A touch sensor and touch panel technology, applied in the field of touch panel, touch sensor and its manufacturing method, can solve the problems of no induced static electricity, defective products, damage, etc., and achieve the effects of cost saving, simple process and improvement of anti-ESD capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Exemplary embodiments will now be described more fully with reference to the accompanying drawings.

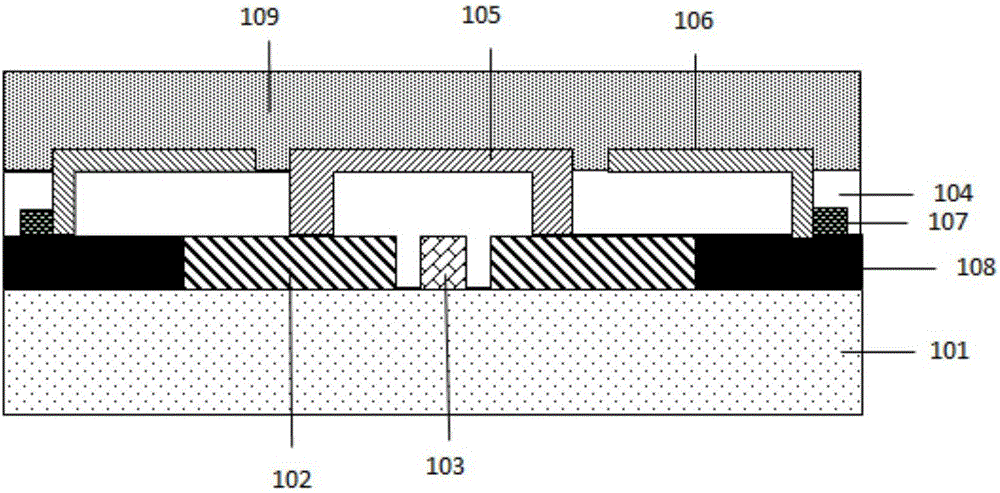

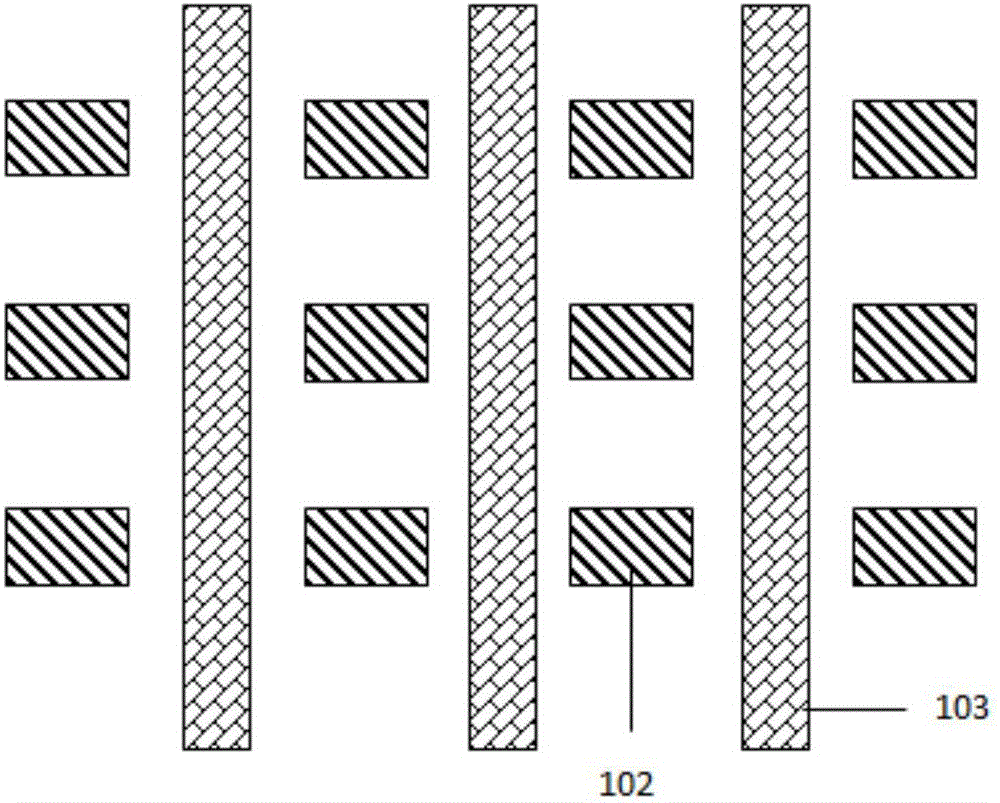

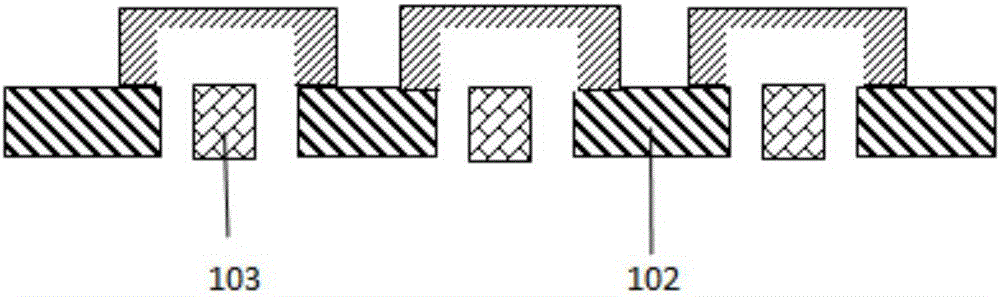

[0049] In one aspect of the present invention, a touch sensor is provided, including a substrate, an electrode layer disposed on the substrate, a first insulating layer disposed on the electrode layer, and a transparent conductive layer disposed on the first insulating layer. Specifically, the electrode layer includes a first electrode and a second electrode isolated from each other; the transparent conductive layer includes a bridge portion configured to bridge the first electrode or the second electrode and an ESD protection portion isolated from the bridge portion.

[0050] In the embodiment of the present invention, the ESD protection part is provided inside the sensor, which can effectively release or shield the static electricity generated inside the sensor, and improve the anti-ESD capability of the functional layer of the sensor. In addition, the ESD protection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com