Matching method of lithium-ion power battery

A power battery, lithium-ion technology, applied in the field of lithium-ion power batteries, can solve the problems of the battery charge and discharge performance cannot be well detected and sorted, the overall performance of the battery pack is poor, and the test conditions are single.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0016] The present invention provides a lithium-ion power battery assembly method, comprising the following steps:

[0017] Step 1. Select the battery whose voltage and internal resistance are within the acceptable range;

[0018] Step 2. Carry out a charge and discharge test on the battery in step (1), and select the battery within the range according to the specified capacity range;

[0019] Step 3, carrying out the polynomial fitting of the charging and discharging time-voltage curve of the battery selected in step (2), the polynomial is expressed as:

[0020] y=ax 6 +bx 5 +cx 4 +dx 3 +ex 2 +fx;

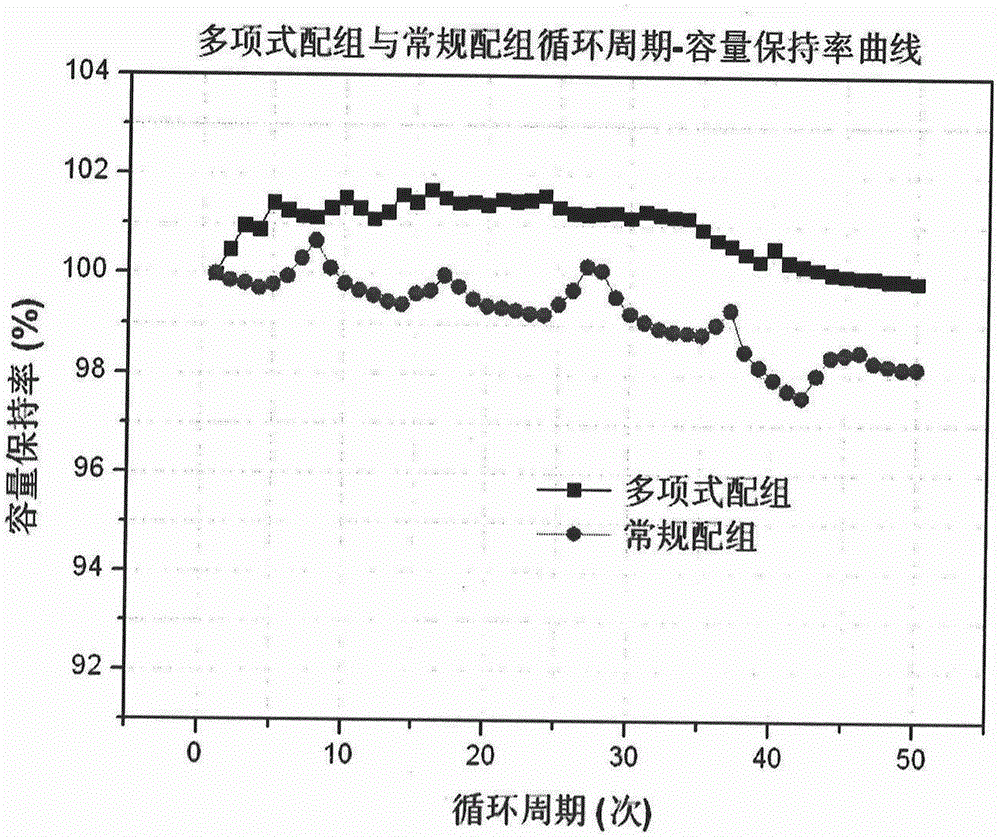

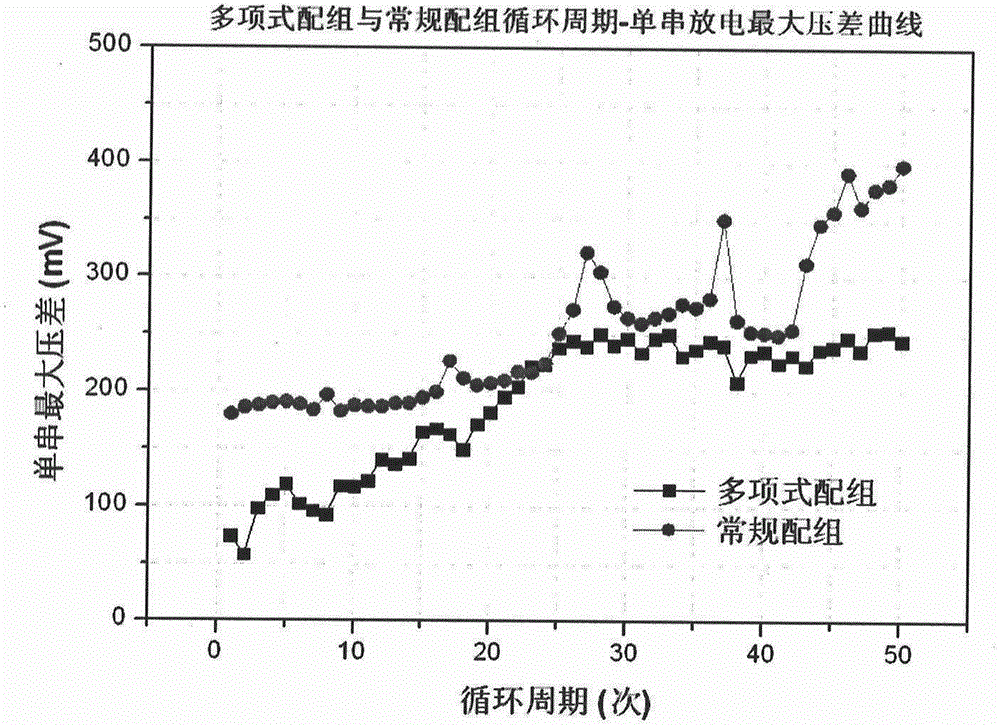

[0021] Step 4. Comparing the coefficients of the fitting equations obtained in step (3), selecting batteries with fitting coefficients within a certain range, and grouping them.

[0022] As a further improvement of the above-mentioned embodiment, the values of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com