An auxiliary tightening type anti-slip grounding wire clamp device

A grounding clamp and anti-slip technology, which is applied in the direction of clamping/spring connection, connection, conductive connection, etc., can solve the problems of inconvenient operation and unfavorable clamping, and achieve convenient and fast operation, increased safety, increased safety and reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

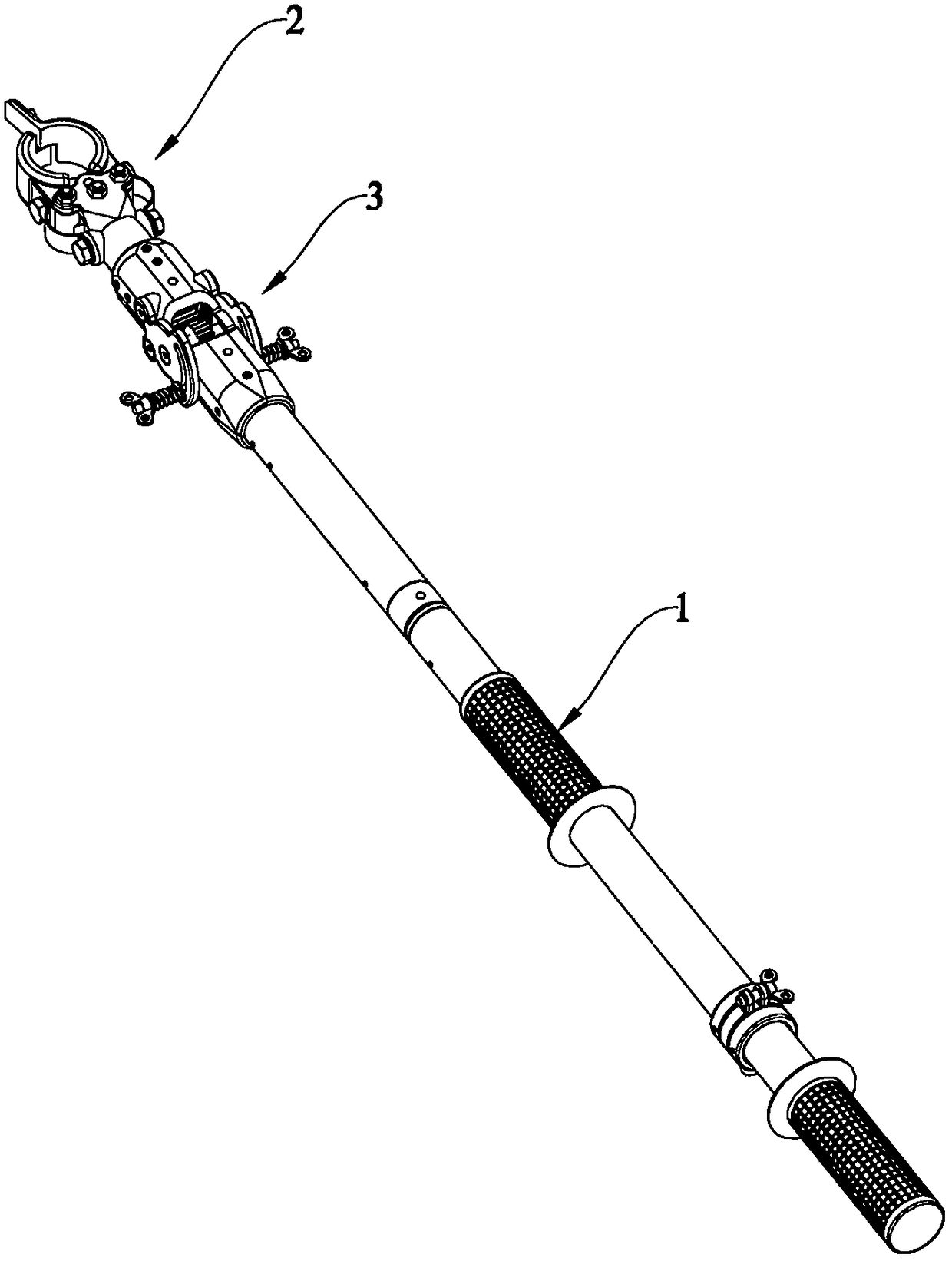

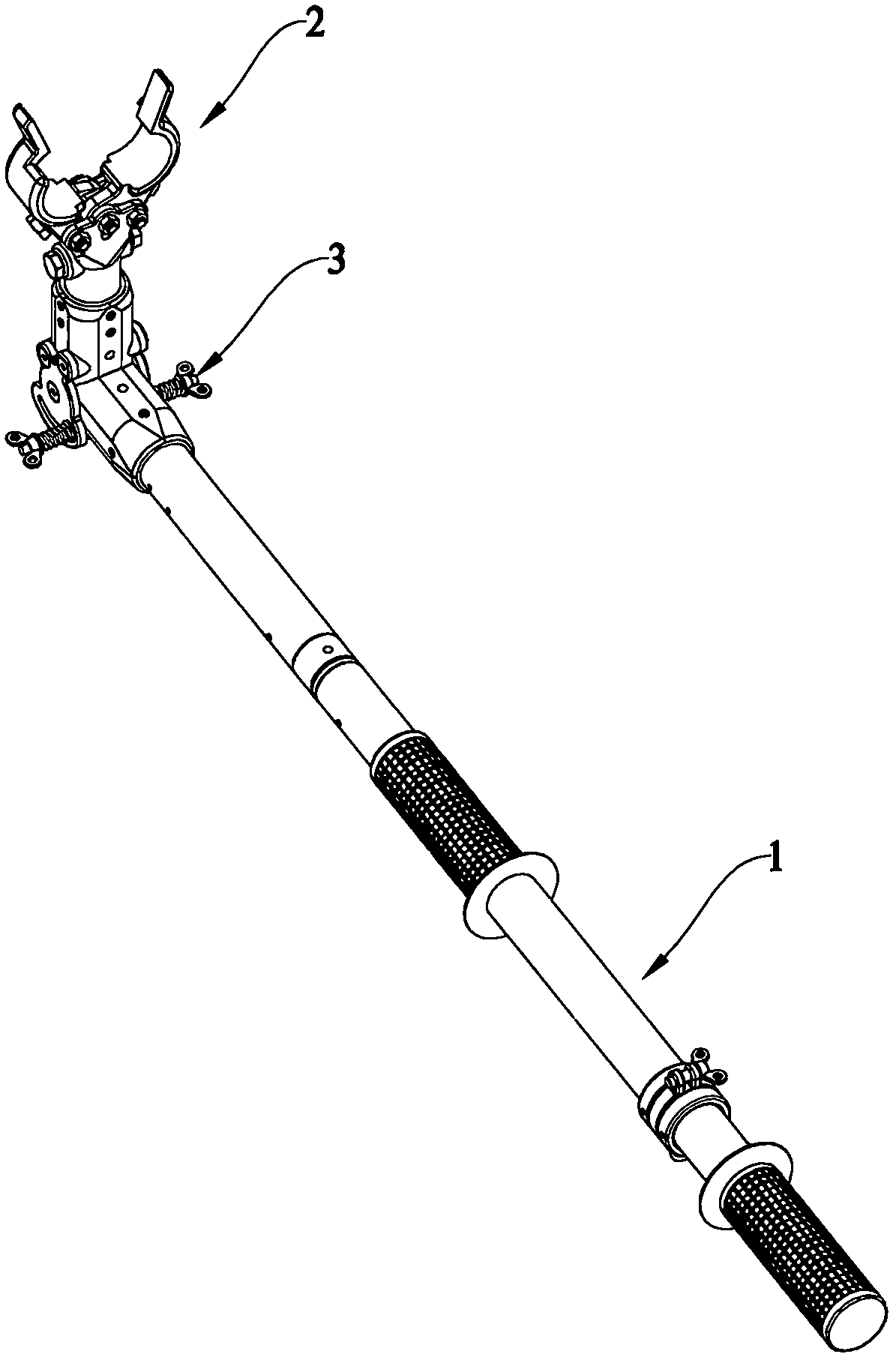

[0036] Such as Figure 1-16 As shown, the embodiment of the present invention comprises a hand-held bar 1, a clamping device 2 and a transmission device 3, and the transmission device 3 is connected to the hand-held bar 1 and the clamping device 2, and is used to convert the rotation of the hand-held bar 1 into the rotation of the clamping device 2 The opening and closing are also used to realize the bending of the clamping device 2 relative to the handle bar 1 . The main structure of its three parts is as follows:

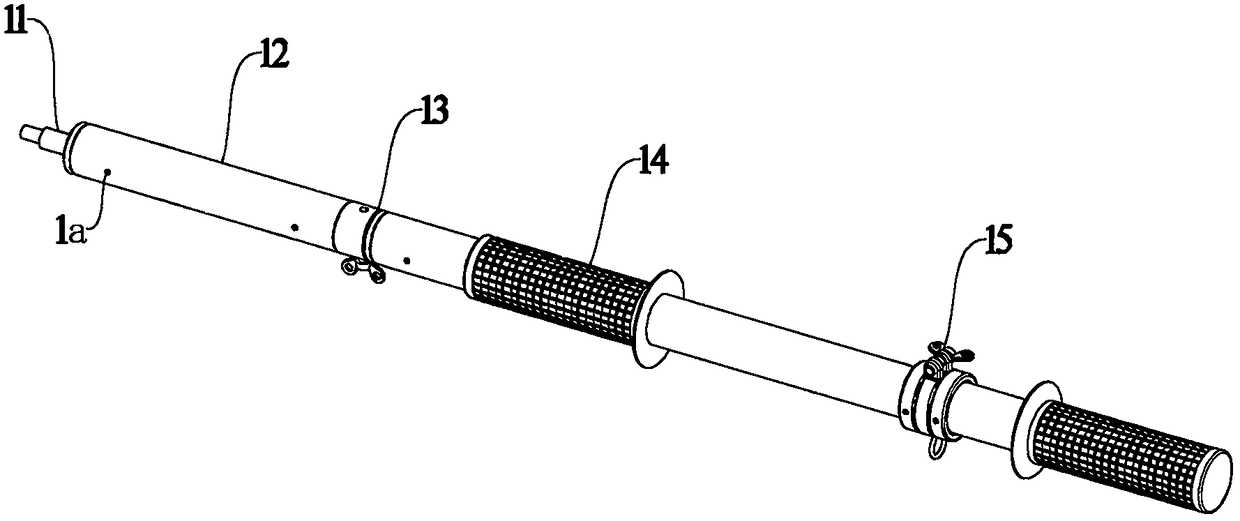

[0037] Hand-held rod 1: including connecting head 11, connecting sleeve 12, sleeve connecting piece 13, anti-slip sleeve 14 and rope part 15, and fixing pin 1a for fixing the above parts, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com