Guardrail surface spraying equipment

A surface spraying and equipment technology, applied in the field of guardrail surface spraying equipment, can solve the problems of low efficiency of spraying equipment, easy rust on the surface, waste of paint, etc., and achieve the effects of stable clamping, reducing inhalation and avoiding turbulence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

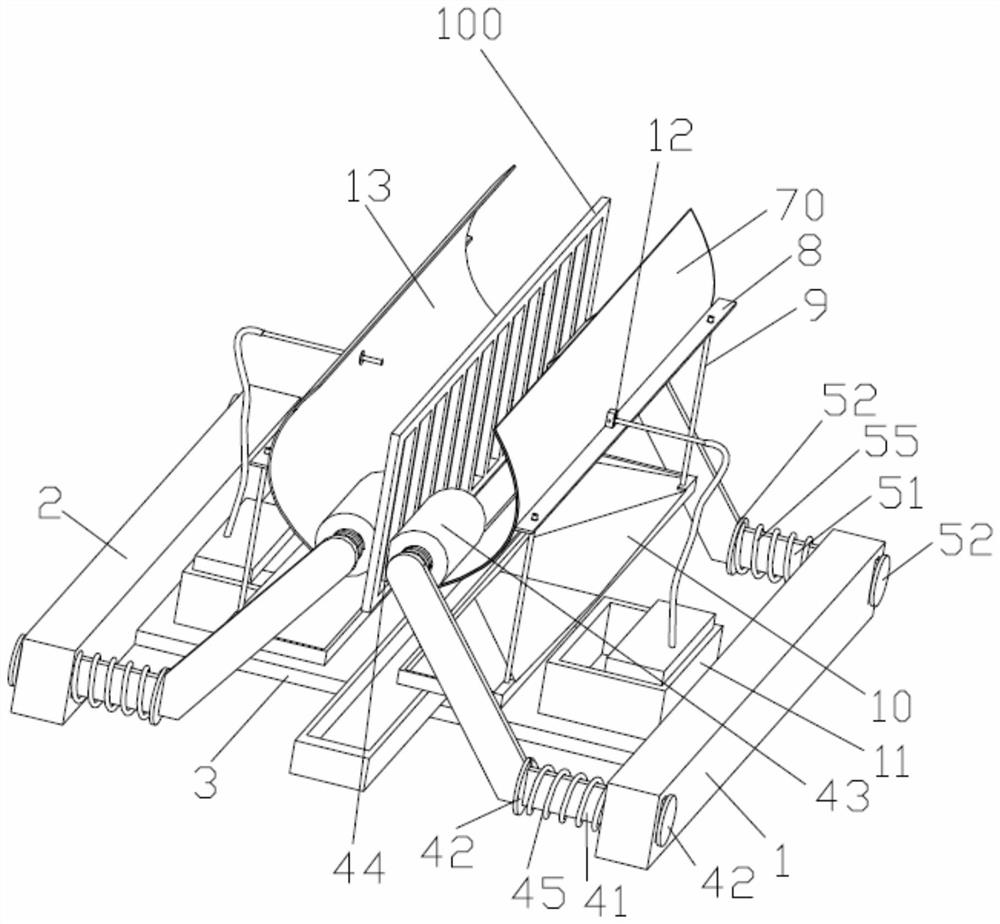

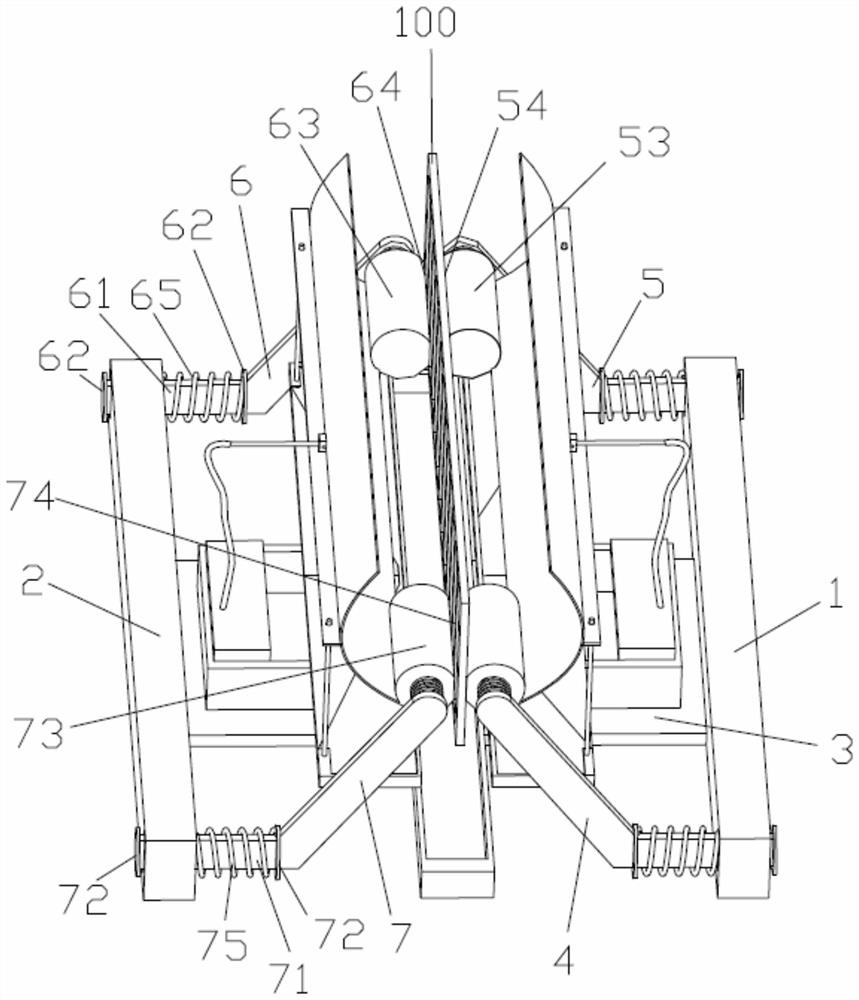

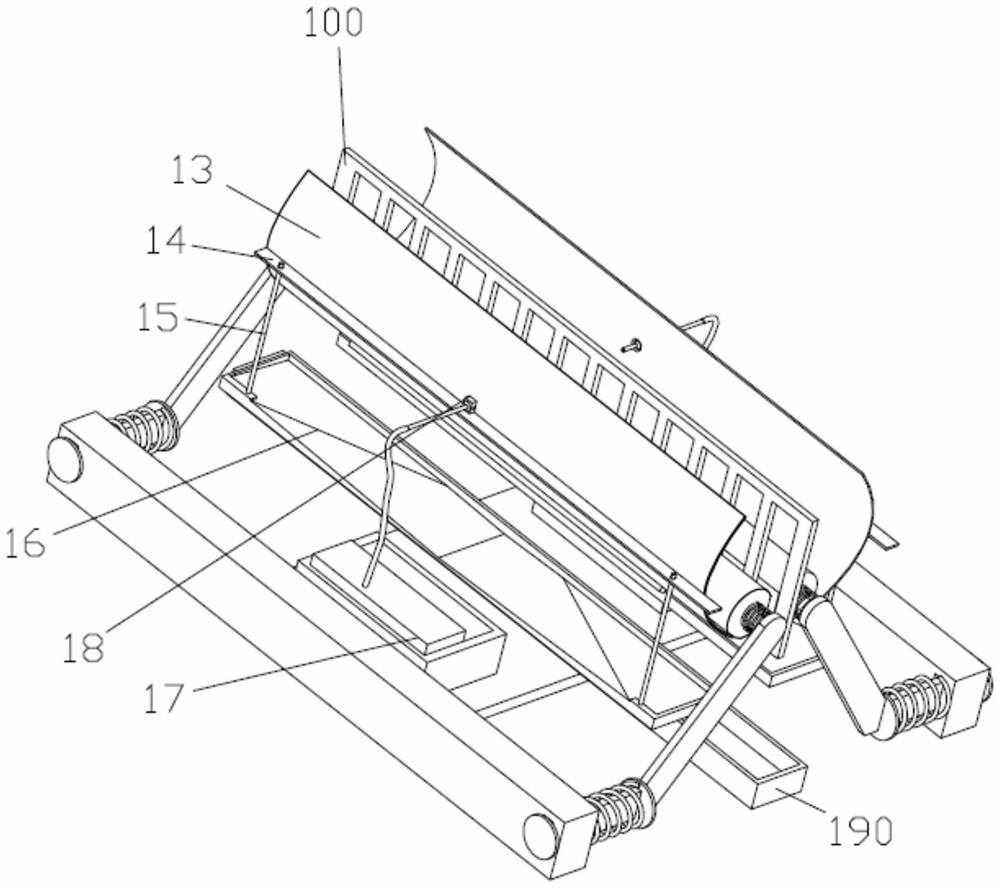

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0029] A guardrail surface spraying method includes the following steps: spraying hot-dip galvanizing on the base layer, and secondly spraying thermoplastic powder coating, wherein the hot-dip galvanizing layer on the surface can play the role of antirust and anticorrosion.

[0030]A new type of coating, specifically a formulation of guardrail surface spraying material (thermoplastic powder coating): it is made of the following raw materials in parts by weight: 15-25 parts of thermosetting acrylic resin, 10-12 parts of aromatic hydrocarbon modified terpene resin , 3-6 parts of bismaleimide resin, 0.3-0.8 parts of dilauryl thiodipropionate, 2-4 parts of hydrogenated ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com