Varistor and its leads

A technology of piezoresistors and leads, which is applied in the direction of piezoresistors, resistors, resistor parts, etc., can solve the problems of small contact area between leads and soldered substrates, high current density of piezoresistors, and poor impact resistance. To reduce the thickness of the silver layer and the amount of the silver layer, increase the contact area, and enhance the impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

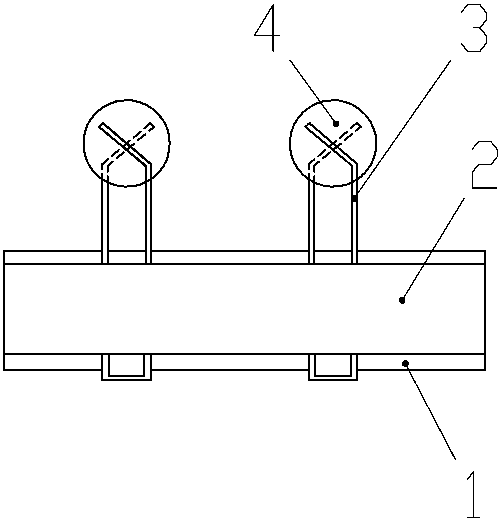

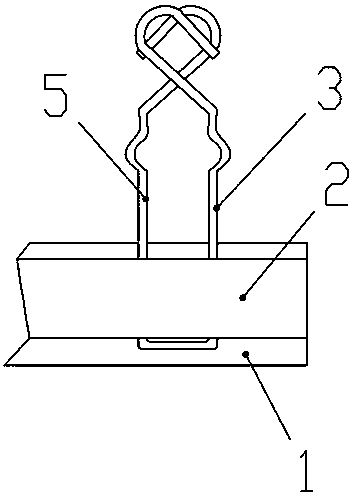

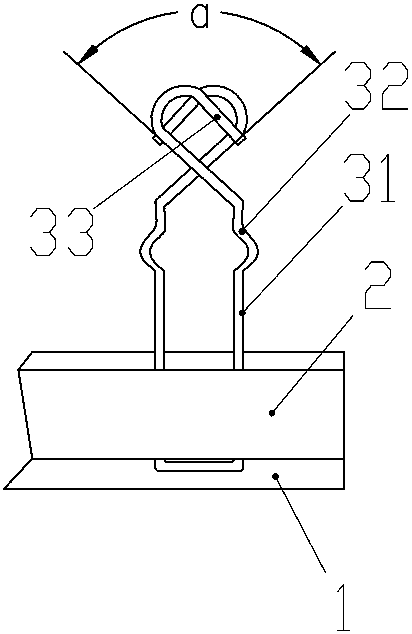

[0033] In this embodiment, the varistor lead whose free end is a U-shaped structure is applied to a 25KS varistor, such as Figure 2 to Figure 4 As shown, the varistor lead includes a first lead 3 and a second lead 5 that are bent into a symmetrical structure along the middle, and the first lead 3 and the second lead 5 include a straight line 31 close to the middle of the bend, Curved section 32 between the U-shaped section 33 of free end and straight section 31 and U-shaped section 33, described straight section 31 is used for fixing with paper tape 1 and adhesive tape 2, the U-shaped of first lead wire 3 and second lead wire 5 The section 33 is used to hold the solder substrate 4 .

[0034] In this example, if figure 2 and image 3 As shown, the lead wire of the present embodiment is a copper wire with a diameter of 1.2 mm, and the lead wire is flattened to 1.4 mm in width of the lead wire of the U-shaped section 33, so that the lead wire width of the U-shaped section 33 ...

Embodiment 2

[0047] Such as Figure 2 to Figure 4 As shown, the varistor lead includes a first lead 3 and a second lead 5 that are bent into a symmetrical structure along the middle, and the first lead 3 and the second lead 5 include a straight line 31 close to the middle of the bend, Curved section 32 between the U-shaped section 33 of free end and straight section 31 and U-shaped section 33, described straight section 31 is used for fixing with paper tape 1 and adhesive tape 2, the U-shaped of first lead wire 3 and second lead wire 5 The section 33 is used to hold the solder substrate 4 .

[0048] In this embodiment, the included angle a of the U-shaped side of the U-shaped section 33 of the first lead 3 and the second lead 5 is 45° in this embodiment. The included angle of the U-shaped side of the U-shaped section of the first lead and the second lead determines the clamping position of the lead on the soldered substrate, and a is set to 45°, which can ensure that the clamping stabilit...

Embodiment 3

[0050] Such as Figure 2 to Figure 4 As shown, the varistor lead includes a first lead 3 and a second lead 5 that are bent into a symmetrical structure along the middle, and the first lead 3 and the second lead 5 include a straight line 31 close to the middle of the bend, Curved section 32 between the U-shaped section 33 of free end and straight section 31 and U-shaped section 33, described straight section 31 is used for fixing with paper tape 1 and adhesive tape 2, the U-shaped of first lead wire 3 and second lead wire 5 The section 33 is used to hold the solder substrate 4 .

[0051] In this embodiment, the included angle a of the U-shaped side of the U-shaped section 33 of the first lead 3 and the second lead 5 is 145° in this embodiment. The included angle of the U-shaped side of the U-shaped section of the first lead and the second lead determines the clamping position of the lead on the soldered substrate, and a is set to 145°, which can ensure that the clamping stabil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com