Construction method for reducing energy consumption of wound-rotor motor

A motor and winding technology, which is applied in the field of metallurgical energy and electricity, can solve the problems of increasing the cost of metallurgical enterprises, wasting electric energy, and high power consumption rate, and achieve the effects of ensuring safe and stable operation, solving large starting torque, and reliable circuit programs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

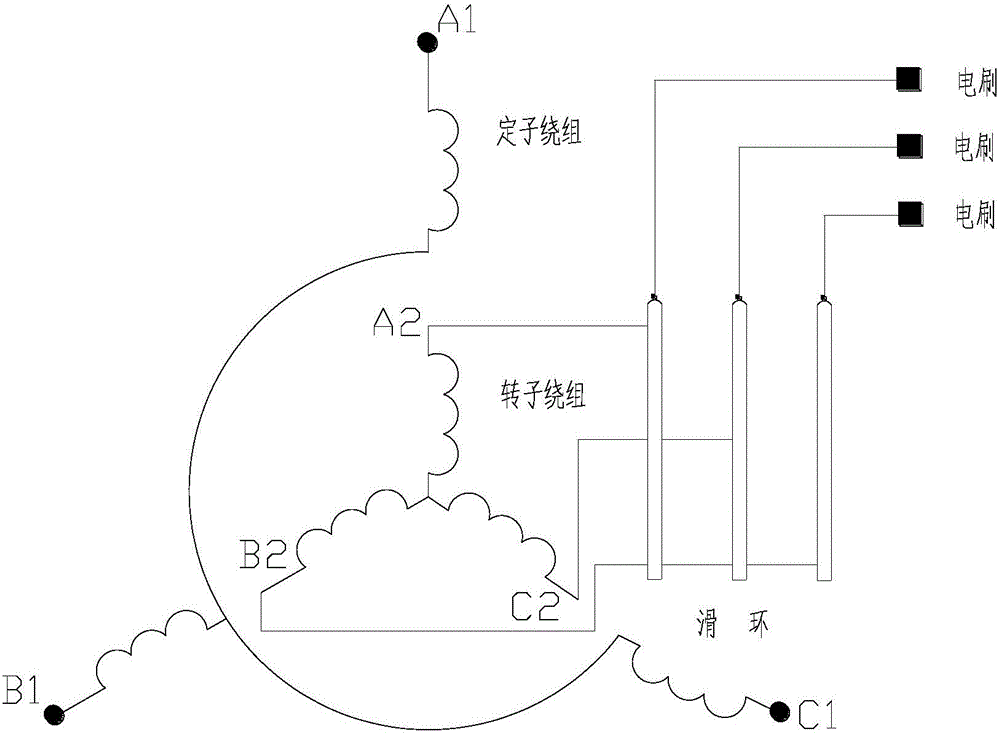

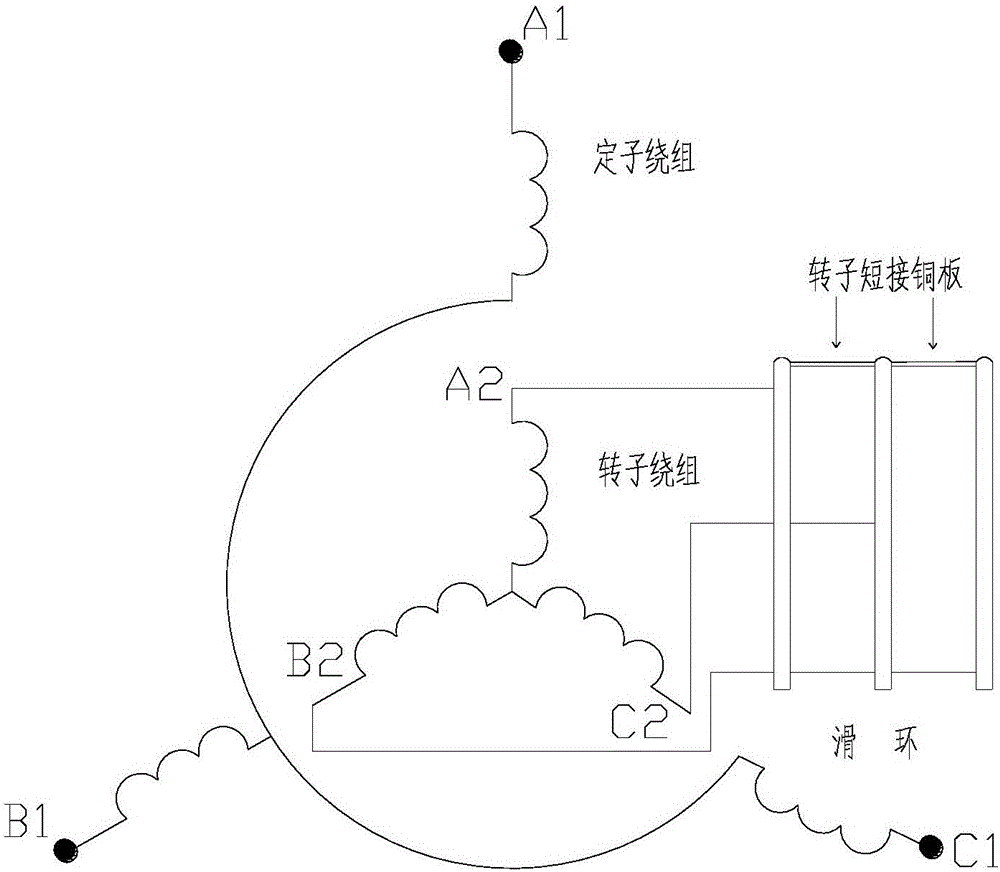

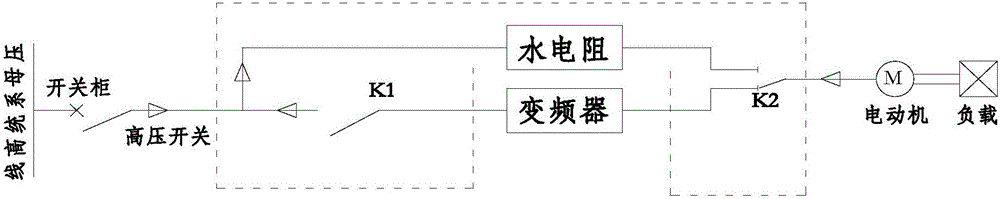

[0019] refer to Figure 1 ~ Figure 3 As shown, the modification method for reducing the energy consumption of a wound-type motor in an embodiment provided by the present invention includes the following steps: firstly short the three lead-out wires connecting the rotor of the wound-type motor with the collector ring through a shorting board Then install a set of control system 1 between the starting power supply and the modified winding motor; short-circuit the rotor through the short-circuit board to make the rotor form a squirrel-cage structure, and at the same time, use the frequency converter 4 to carry out the modified motor Start, not only start smoothly, but also save energy and electricity, solve the problem of large starting torque and high power consumption of wound motors, and avoid the huge impact of 7 times the starting current of wound m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com