A power module for a power analyzer

A power module and power analysis technology, applied in the direction of instruments, electrical components, adjusting electrical variables, etc., can solve problems such as increasing the risk of errors, increasing workload, etc., to prevent device damage, eliminate ripple and noise, and increase output. The effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

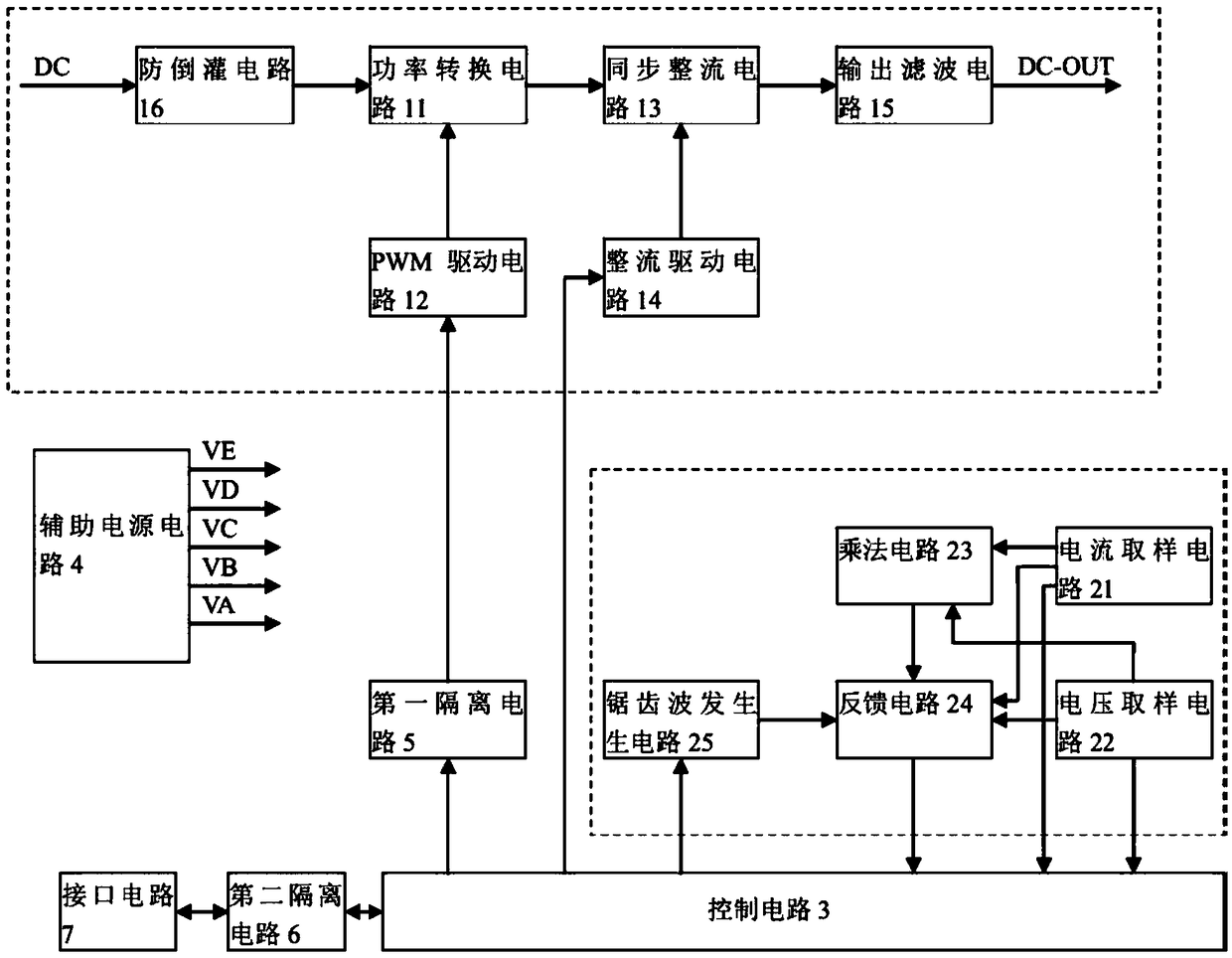

[0066] Embodiment 1: as figure 1 As shown, this embodiment provides a power module for a power analyzer, including a control circuit, a power conversion module, and a sawtooth wave module;

[0067] The sawtooth wave module includes a current sampling circuit, a voltage sampling circuit, a multiplication circuit, a feedback circuit, and a sawtooth wave generating circuit; the current sampling circuit and the voltage sampling circuit collect samples from the output end and / or the load end of the power conversion circuit current and sampling voltage, and sending the sampling current and sampling voltage to the multiplication circuit and the feedback circuit respectively;

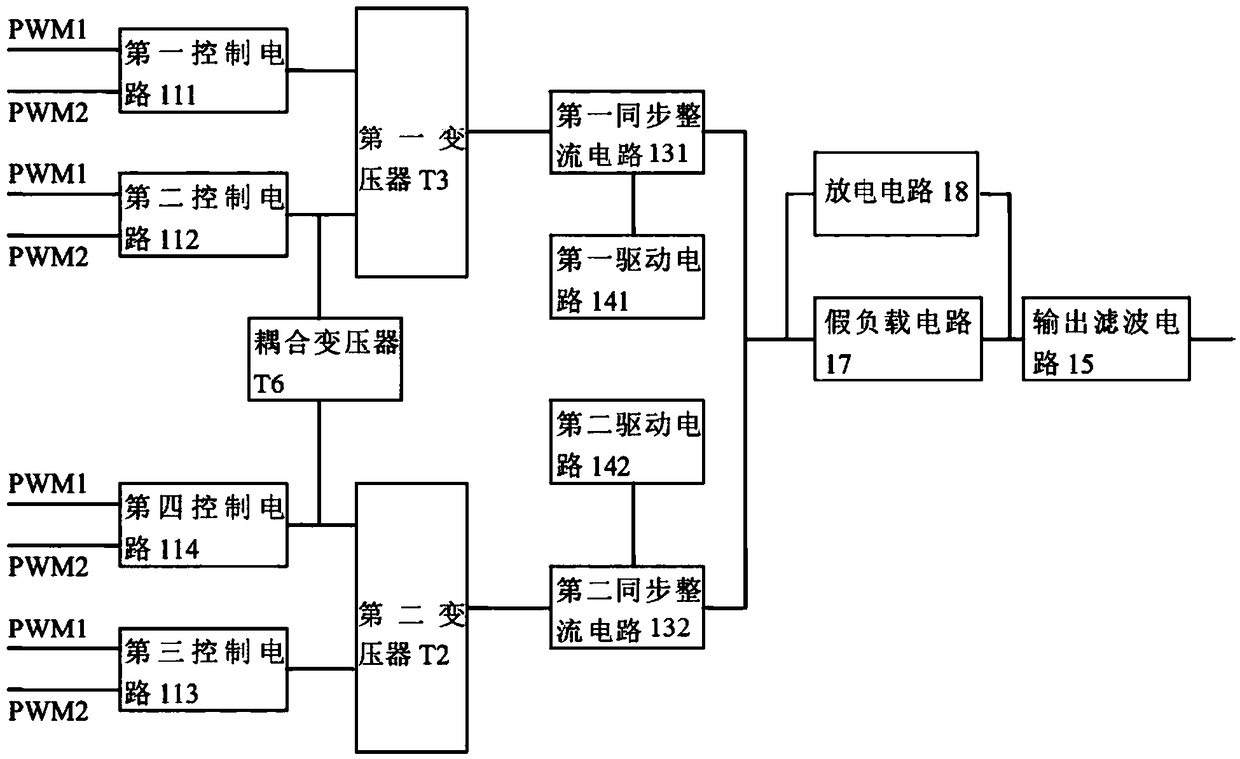

[0068] The power conversion module includes a PWM drive circuit, a power conversion circuit, a rectification drive circuit, a synchronous rectification circuit and an output filter circuit;

[0069] The control circuit sends a sawtooth wave control signal to the sawtooth wave generation circuit to generate a r...

Embodiment 2

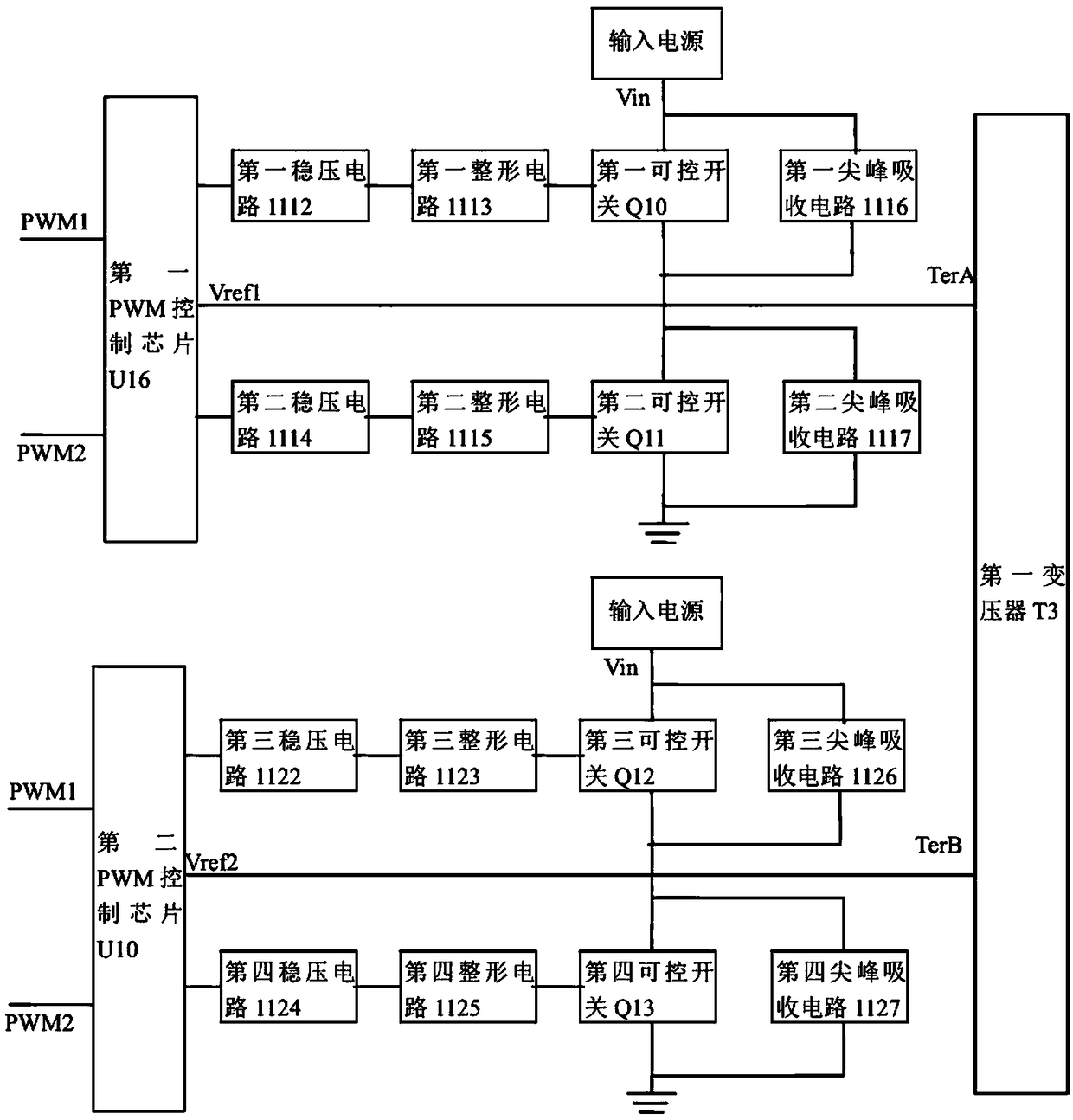

[0095] Embodiment 2: as Figure 3a , Figure 4a As shown, the difference between this embodiment and Embodiment 1 is that, in the first control circuit 111, a first PWM drive chip U16 is provided between the first controllable switch Q10 and the second controllable switch Q11. The voltage stabilizing circuit 1112, the first shaping circuit 1113; the first controllable switch Q10 and the first peak absorbing circuit 1116 are also connected in parallel between the power supply input end and the first end of the primary side of the first transformer T3; The second controllable switch Q11 and the second peak absorbing circuit 1117 are connected in parallel between the first terminal of the primary side of the first transformer T3 and the ground;

[0096] In the second control circuit 112, a second voltage stabilizing circuit 1114 and a second shaping circuit 1115 are further included between the second PWM drive chip U10 and the third controllable switch Q12 and the fourth contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com