Automatic ice-melting conductor and ice-melting equipment adopting same

A self-melting ice and conductor technology, applied in the direction of the heating element shape, etc., can solve the problems of poor maintenance and inconvenient length division

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] See attached Figure 1-7 .

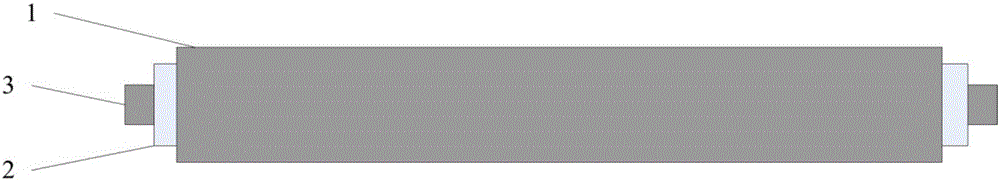

[0060] The present invention uses a self-melting ice conductor 20 that uses a part of the conductor itself as a heating element, and the ice-melting equipment is directly connected to the inner conductor 3 and the outer conductor 1 of the self-melting ice conductor 20 .

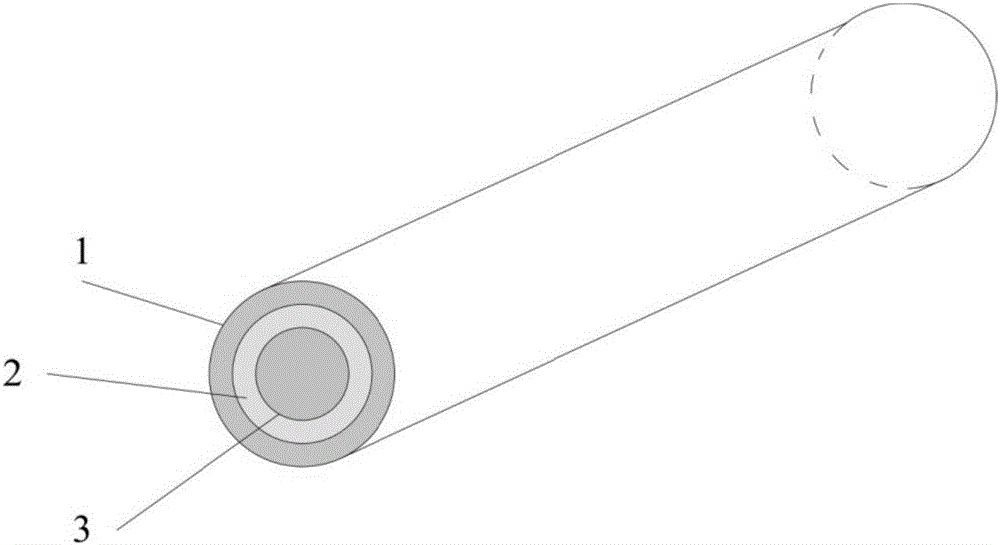

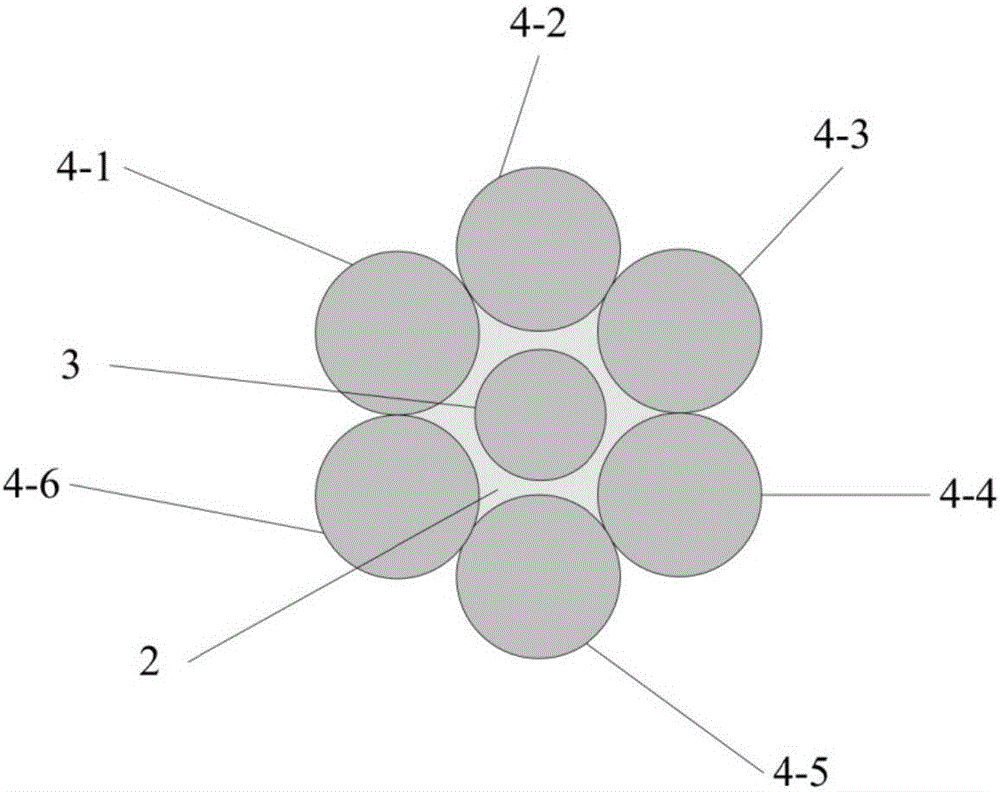

[0061] The self-melting ice conductor 20 is in the form of a coaxial cable, including an outer conductor 1 , a heating material 2 and an inner conductor 3 . The inner conductor is a cylindrical metal, and the heating material is a heating material with a positive temperature coefficient effect. The heating material 2 surrounds the outer surface of the inner conductor 3 and completely surrounds the outer circumference of the inner conductor, so that the inner and outer conductors are completely isolated and the inner and outer conductors are prevented from short circuiting. The inner surface of the heating material is in full contact with the outer surface of the inner cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com