Socks

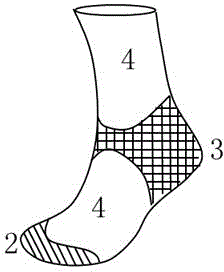

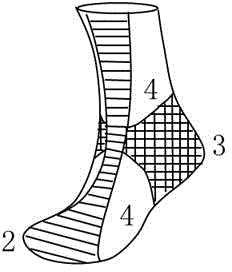

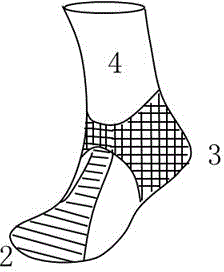

A sock and fabric technology, applied in the field of textiles, can solve problems such as heel misalignment, poor movement following, and elongated toes, achieving good air permeability, not easy to slip off, misalignment, and easy to put on and take off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Select 167dtex-48f-cross-section PET DTY, 30S T / C blended yarn (65:35), 95dtex-36f-PET strong twist yarn (Z twist, 2000 twist / m), use air layer structure to weave to obtain compression elasticity The fabric with a wear rate of 90% and a wear reduction rate of 9% is used as the bottom 1 fabric; 65% PET FDY and 35% Ny FDY are selected, and the deer tissue is used for weaving to obtain a ventilation volume of 42 cm 3 / cm 2 The fabric of / s is used as the fabric of the instep part 2 covering the instep; PU and PET FDY (5:95) are selected, and plain stitches are used for weaving to obtain an elongation rate of 80%, and the elongation stress at 30% elongation is 6.2N fabric with an elongation recovery rate of 90% is used as the heel part 3 fabric covering the heel; PU and PET FDY (12:88) are selected, and the elongation rate of 178% and 30% elongation are formed by using a plain stitch A fabric having an elongation stress of 1.1 N and an elongation recovery rate of 91% was u...

Embodiment 2

[0070] 167dtex-48f-star-shaped section PET DTY, 40S T / C blended yarn (65:35), 110dtex-36f-Ny DTY were selected, and the compression elastic rate was 89% and the wear loss rate was obtained by weaving with air layer structure. 8% of the fabric is used as the bottom 1 fabric; PET FDY and Ny FDY (65:35) are selected, and deer seed tissue is used for weaving to obtain a ventilation volume of 42 cm 3 / cm 2 The fabric of / s is used as the fabric of the instep part 2 covering the instep; PU and PET DTY (9:91) are selected, and plain stitches are used for weaving to obtain an elongation rate of 150%, and the elongation stress at 30% elongation is 5.0N fabric with an elongation recovery rate of 90% is used as the heel part 3 fabric covering the heel; PU and PET DTY (20:80) are selected, and the elongation rate of 200% and 30% elongation are formed by using a plain stitch A fabric having an elongation stress of 1 N and an elongation recovery rate of 93% was used as the fabric covering ...

Embodiment 3

[0073] 84dtex-36f-cross-section PET DTY, 30S 100% cotton spun yarn, 50dtex-72f-PET DTY, 167dtex-96f-PET DTY are selected, and the compression elastic rate is 84% and the wear loss rate is obtained by weaving with air layer structure 10% of the fabric is used as the sole fabric of the foot; PET FDY and Ny FDY (65:35) are selected, and deer seed tissue is used for weaving to obtain a ventilation volume of 42 cm 3 / cm 2 The fabric of / s is used as the fabric of the instep part 2 covering the instep; PU and Ny DTY (11:89) are selected, and plain stitches are used for weaving to obtain an elongation rate of 140%, and the elongation stress at 30% elongation is 5.2N fabric with an elongation recovery rate of 93% is used as the heel part 3 fabric covering the heel; PU and Ny FDY (12:88) are selected, and the elongation rate of 170% and 30% elongation are formed by velveteen weave A fabric having an elongation stress of 1.5 N and an elongation recovery rate of 94% was used as the fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation stress | aaaaa | aaaaa |

| Elongation stress | aaaaa | aaaaa |

| Elongation stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com