Novel internal vibration type vibrating screen

A vibrating screen, a new type of technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of high price and increased cost, and achieve the effect of low maintenance cost, reliable operation and ingenious design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention provides a new type of internal vibration vibrating screen, which is ingenious in design, low in failure rate, low in maintenance cost, and more reliable in operation. The internal vibration structure can effectively prevent resonance, maintain the balance of the screen, and output stable simple harmonic vibration. , and adopts a double-layer screen structure, which can ensure the full circulation of materials and effectively filter impurities.

[0016] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

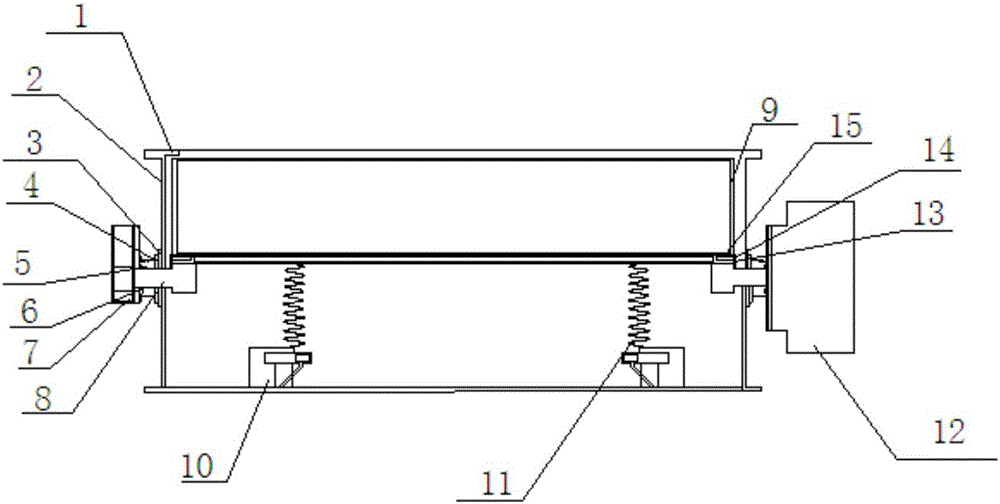

[0017] Such as figure 1 As shown, a new type of internal vibration vibrating screen described in this embodiment includes a screen outer ring 2, a spring frame 10 and a spring 11, and also includes a connecting shaft 8, a motor 12, a reinforcing ring 13, and a bottom screen 14 , pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com