Use method for underwater friction stitch welding draining device

A drainage device and friction stitch welding technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as poor welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

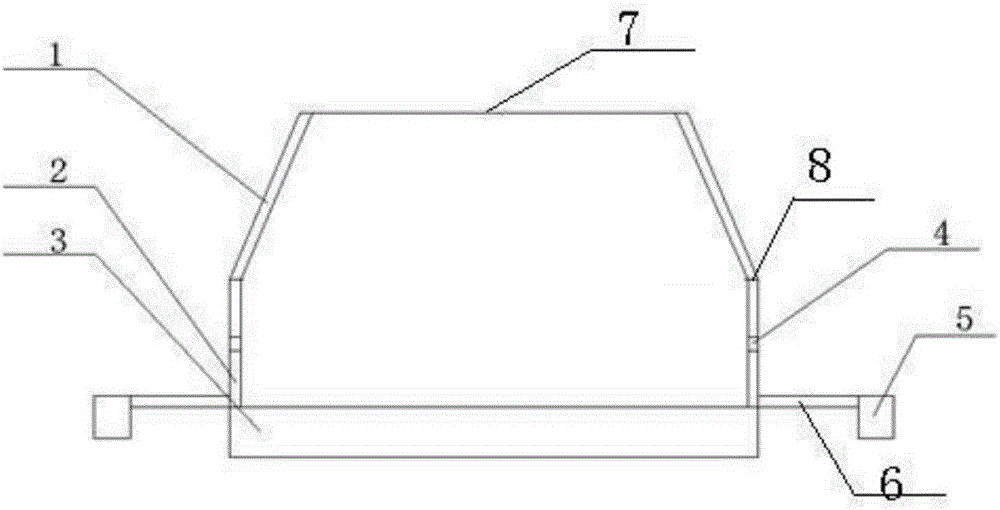

[0018] as attached figure 1 As shown, the structure diagram of the drainage device of the present invention, wherein 1 is a flexible shell, 2 is a flange, 3 is a sponge gasket, 4 is a vent hole, 5 is a magnetic sucker, 6 is a backing plate, 7 is a mounting hole, 8 For connecting clamps.

[0019] The flexible casing, the flange, the sponge gasket and the surface of the workpiece constitute the air chamber, which mainly performs the drainage and sealing of the welding area, and also includes the matching gas transmission device (not shown in the figure).

[0020] The flexible shell is in the shape of a conical cylinder. At the uppermost end of the entire device, a mounting hole is provided in the center of the top of the flexible shell for connecting the spindle head of the welding equipment and sealing it. The lower end surface of the flexible she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com