Angle cylinder lever lifting clamping mechanism

A technology of a corner cylinder and a clamping mechanism, which is applied in the field of fixtures and fixtures, can solve the problems affecting the service life of the corner cylinder and the different axes of the corner cylinder, and achieve the effects of simple and reasonable structure, increased pressing force, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

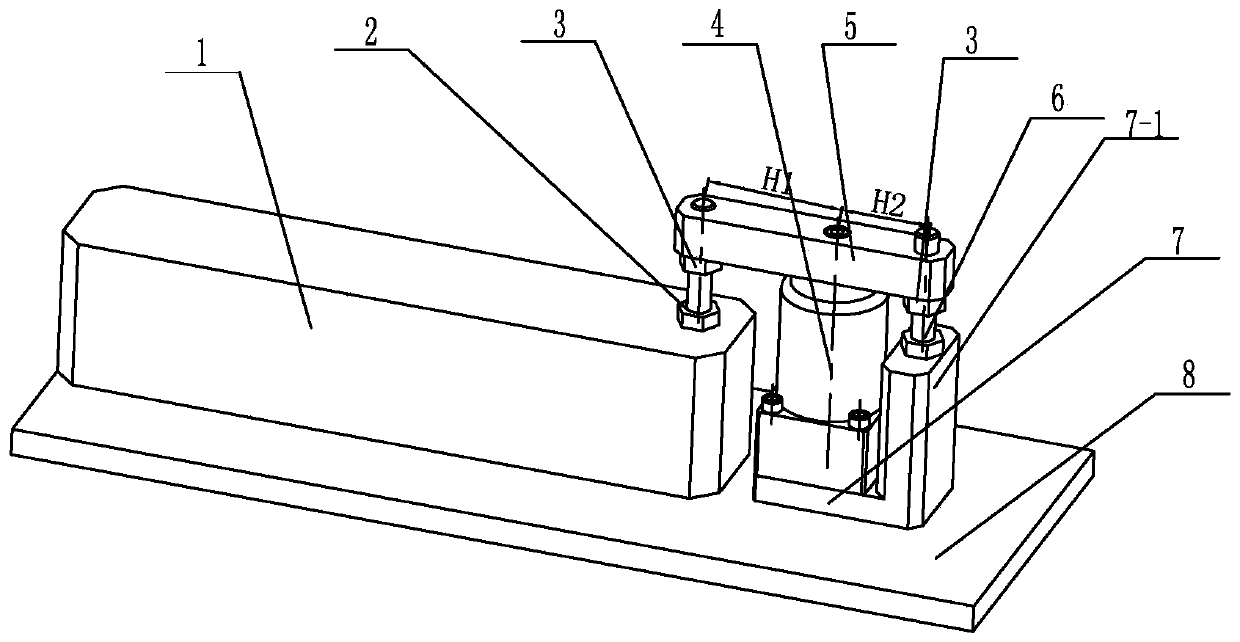

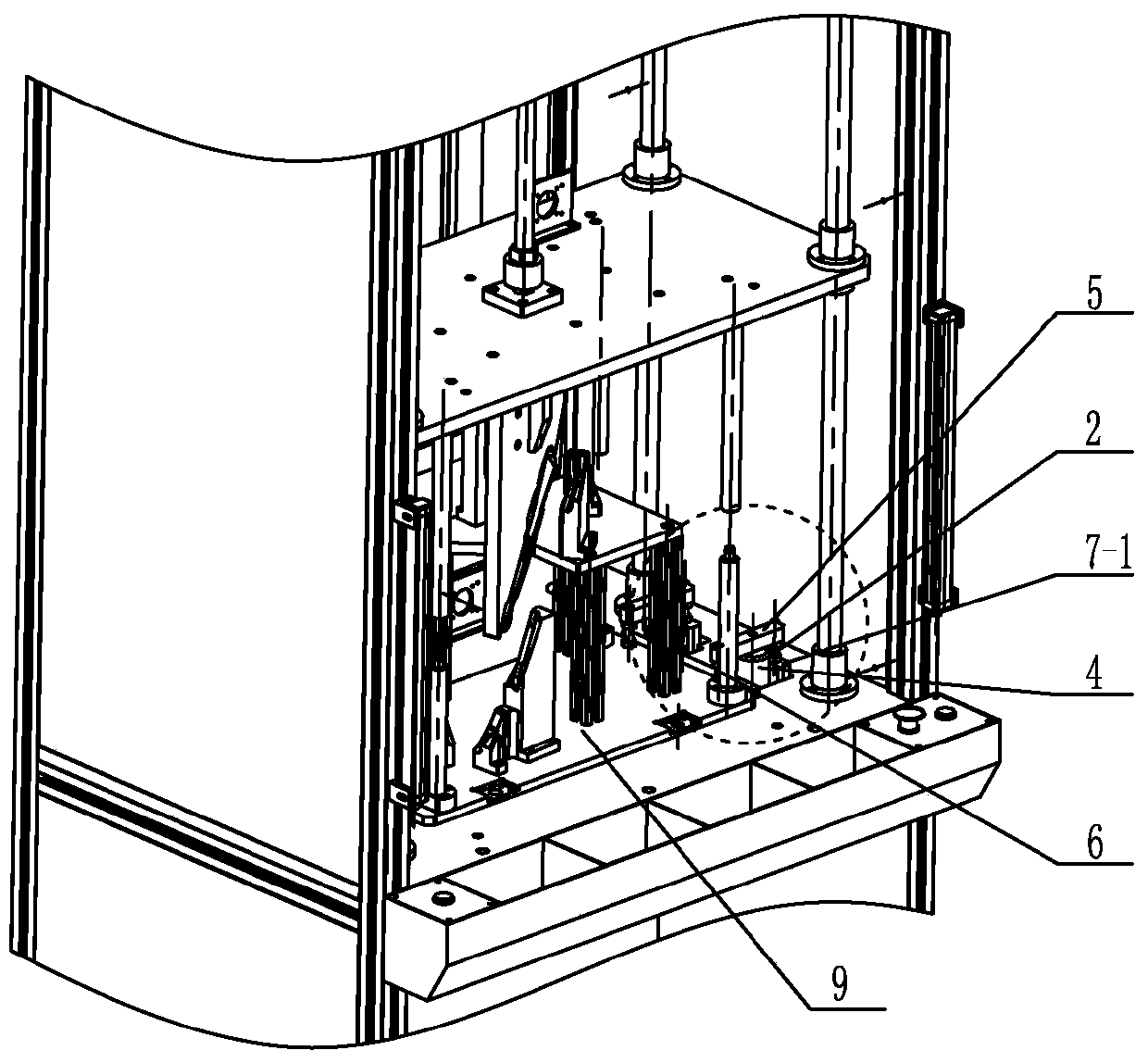

[0012] See figure 1 , 2 As shown, the angle cylinder lever lifting clamping mechanism of the present invention includes an installation platform base plate 8 and an angle cylinder 4 installed on the installation platform base plate 8, the angle cylinder 4 is installed on the installation platform base plate 8 through the cylinder mounting seat 7, and the angle cylinder The piston rod of 4 is connected with the lever support arm 5, and the lever support arm 5 is driven by the piston rod of the corner cylinder 4 to rotate and move up and down, and then clamp the workpiece 1 or loosen the workpiece 1 and rotate 90 degrees to quickly assemble the workpiece 1. folder. See figure 1 As shown, one side of the lever support arm 5 of the present invention is connected with the height-adjustable pressing arm 2, and the other side is connected with the height-adjustable follow-up press arm 6, by adjusting the height of the press arm 2 and the follow-up press arm 6 , can adjust the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com