Multifunctional machining clamp for clamping

A multi-functional, machining technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of not suitable for single-piece small batch production, single type of clamping workpiece, small clamping stroke range, etc. To achieve the effect of convenient clamping, reducing process cost and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

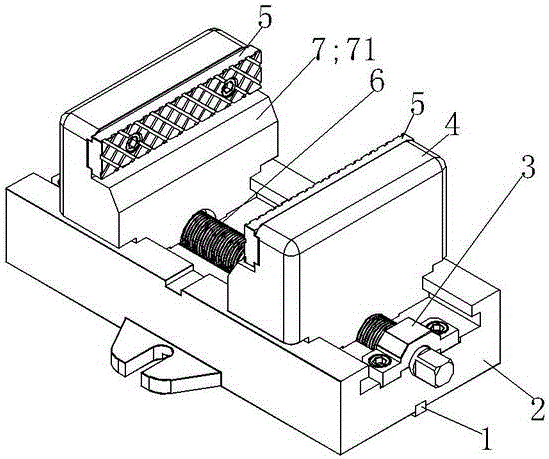

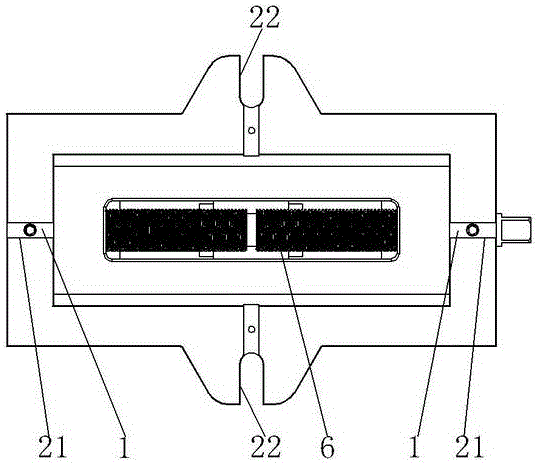

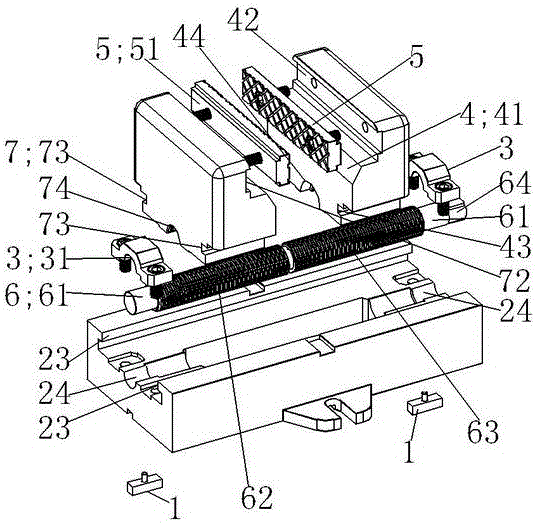

[0020] see Figure 1 to Figure 6 Shown, the present invention is made of two pairs of fixed keys 1, base 2, two bearing caps 3, right-handed jaw body 4, two reticulated flat splints 5, leading screw 6, left-handed jaw body 7, two It consists of a horizontal axis splint 8, two V-shaped splints 9 and two double V-shaped splints 10;

[0021] The base 2 is provided with two keyways 21, two semi-closed handle holes 22, two outer rectangular guide rails 23, and two half-bearing holes 24; the bearing cover 3 is provided with a half-bearing hole 31; the right-handed jaw body 4 is provided with Inclined surface 41, rectangular groove 42, two inner rectangular guide rails 43 and half right-handed threaded hole 44; Mesh plain splint 5 is provided with rectangular boss 51; Lead screw 6 is provided with two journals 61, left-handed thread 62, right-handed Spiral thread 63 and square flat head 64; Left-handed jaw body 7 is provided with inclined plane 71, rectangular groove 72, two inner r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com