Integrated furnace bottom for producing titanium tetrachloride by chlorination furnace

A technology of titanium tetrachloride and chlorination furnace, which is applied in the direction of titanium tetrachloride and titanium halide, can solve the problems of high cost of chlorine gas feeding tray, and achieve the goal of solving high cost, eliminating the risk of leakage and reducing labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

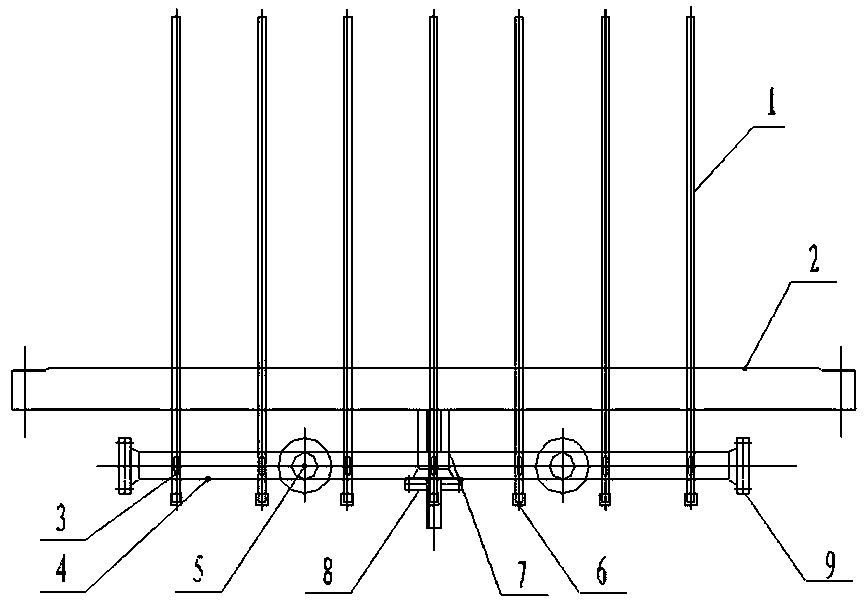

[0022] Such as figure 1 As shown, the integrated furnace bottom of the chlorination furnace for producing titanium tetrachloride includes distribution pipe 1, circular furnace bottom flange 2, drawing groove 3, circular feeding pan 4, air inlet 5, plug cap 6, Slag discharge pipe 7, blind plate 8 and blocking plate 9;

[0023] A circular feeding pan 4 is provided below the circular furnace bottom flange 2, and more than two holes evenly arranged are opened on the surface of the pan;

[0024] A blocking plate 9 is provided on the circumferential surface of the circular feeding tray 4;

[0025] The circular feeding tray 4 is provided with more than two air inlets 5;

[0026] There are multiple distribution pipes 1, one end of which passes through the furnace bottom flange 2 and the feeding tray 4 and is arranged under the feeding tray 4, and the ports are pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com