Tool wear detection method based on minimum enclosing rectangle

A circumscribed rectangle and tool wear technology, which is applied in the direction of manufacturing tools, measuring/indicating equipment, instruments, etc., can solve the problems of large environmental impact, blurred images that cannot be recognized, and the inability to accurately obtain the amount of tool wear. The effect of small noise influence and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technology of the present invention will be further described in detail below with reference to the accompanying drawings.

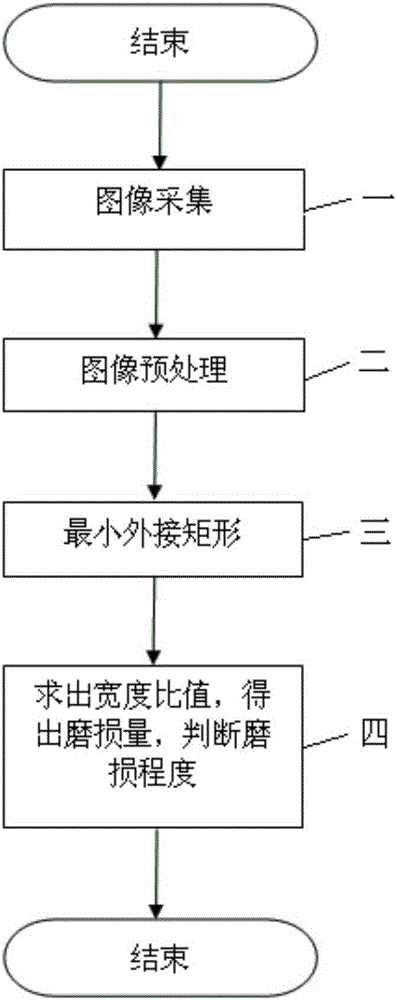

[0039] Such as Figure 1-Figure 9 Explain that the tool wear detection method based on the minimum circumscribed rectangle includes the following steps:

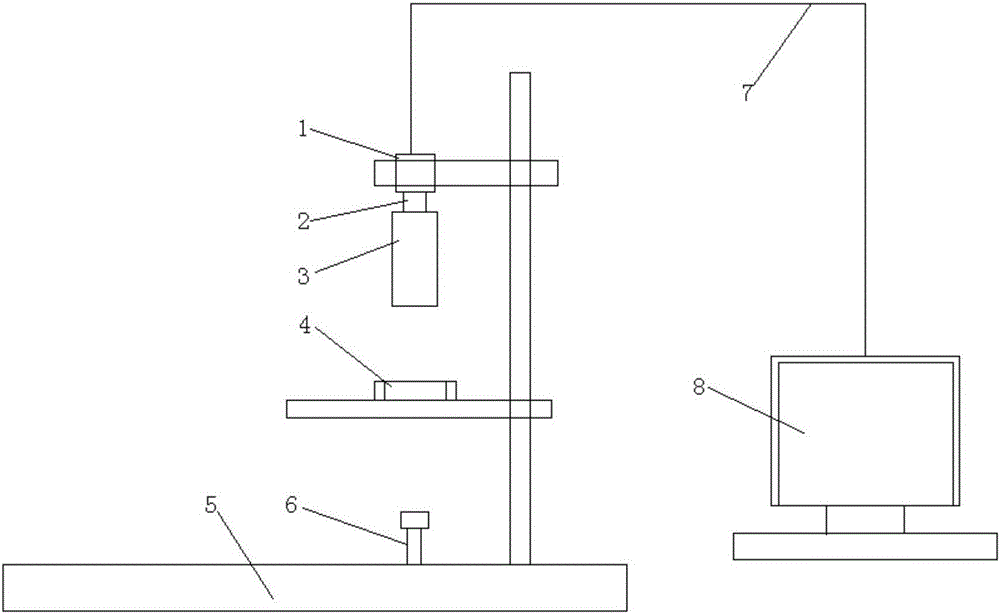

[0040] Step 1, using the image acquisition system to collect tool wear images, and transmitting the collected images to the computer;

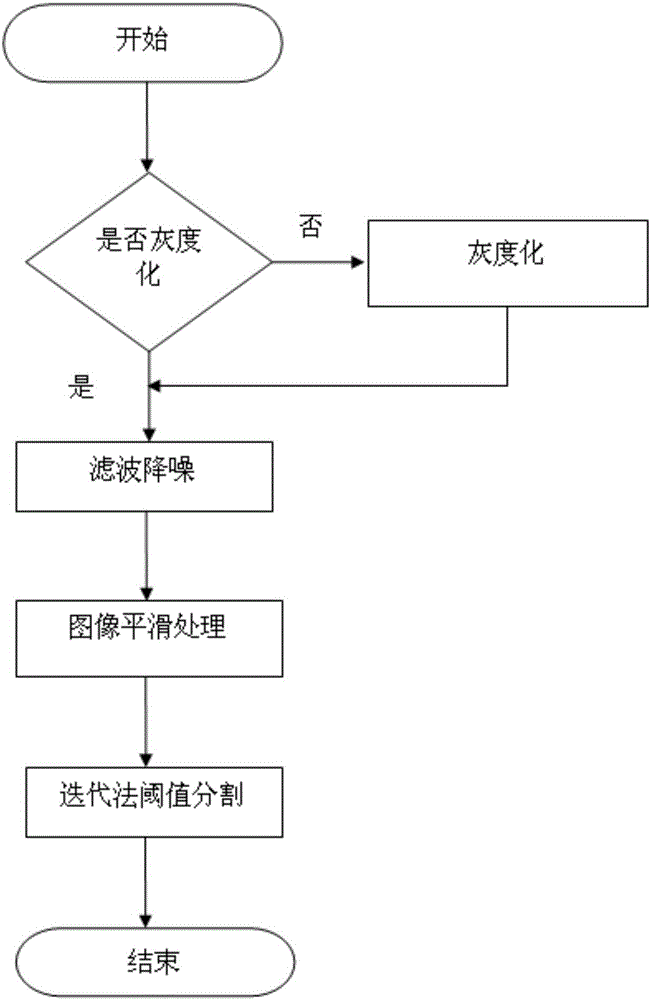

[0041] Step 2. Perform image preprocessing on the wear image collected in step 1, including image grayscale, median filter noise reduction processing, image smoothing processing, and image iteration threshold segmentation;

[0042] Step 3, using the minimum circumscribed rectangle algorithm to obtain the minimum circumscribed rectangle of the tool wear area with the image preprocessed in step 2, and obtain the width of the minimum circumscribed rectangle;

[0043] Step 4: Comparing the width of the minimum circumscribed rectangle of the tool wear area obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com