Dual-temperature-control double-loop cooling system of bottle cover compression molding machine

A cooling system and molding machine technology, applied to other household appliances, household components, household appliances, etc., can solve the problems of large watermark on the surface of the bottle cap, screw thread pulling of the bottle cap, condensation on the machine and mold, etc., and achieve the processing technology. And the effect of simplifying the processing method, reducing the maintenance cost and reducing the overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

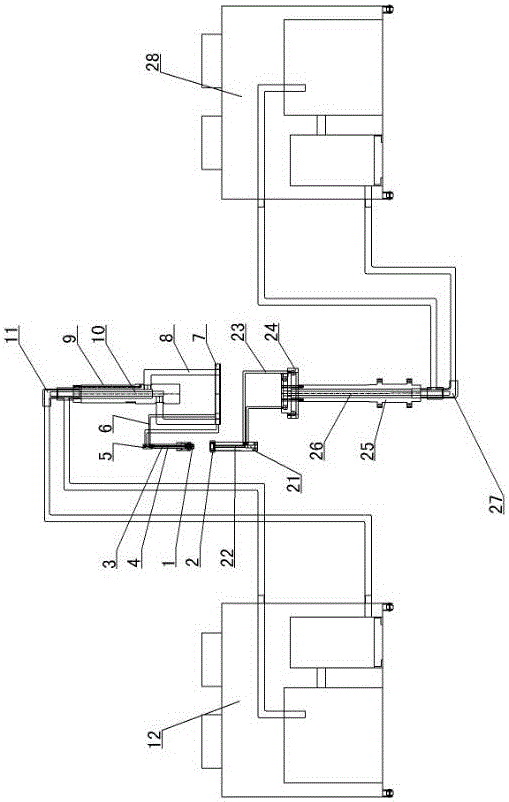

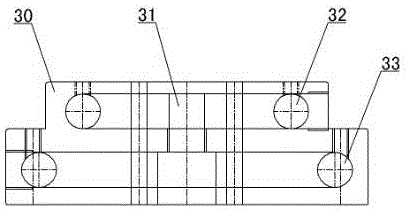

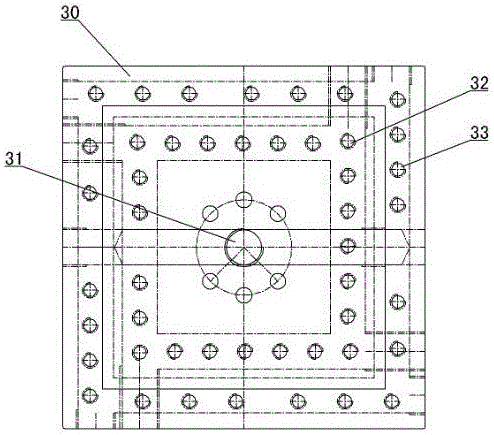

[0010] The invention relates to a dual-temperature-control dual-circuit cooling system of a bottle cap molding machine, such as figure 1 — image 3 As shown, the upper mold 1 and the lower mold 2 of the bottle cap compression molding machine are included. The upper mold 1 and the lower mold 2 are respectively provided with cooling circuits, and the cooling circuit of the upper mold 1 includes the upper mold guide on the upper mold. The upper mold cooling water hole 4 is opened in the rod 3, the upper mold cooling water hole is connected to the upper mold cold water joint 5, the upper mold cold water joint 5 is connected to the upper mold water distribution plate 7 through the upper mold cold water pipe 6, and the upper mold water distribution plate is passed through The mold water pipe 8 is connected to the upper mold transmission spindle 9, the upper mold transmission spindle is provided with an upper mold waterway 10, the upper mold waterway is connected to the upper mold wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com