Graphene oxide composite electronic heater

A composite and graphene technology, applied in the direction of electrothermal systems, chemical instruments and methods, synthetic resin layered products, etc., can solve the problem of less addition, achieve increased heating power, uniform distribution, and meet the needs of high-power heating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

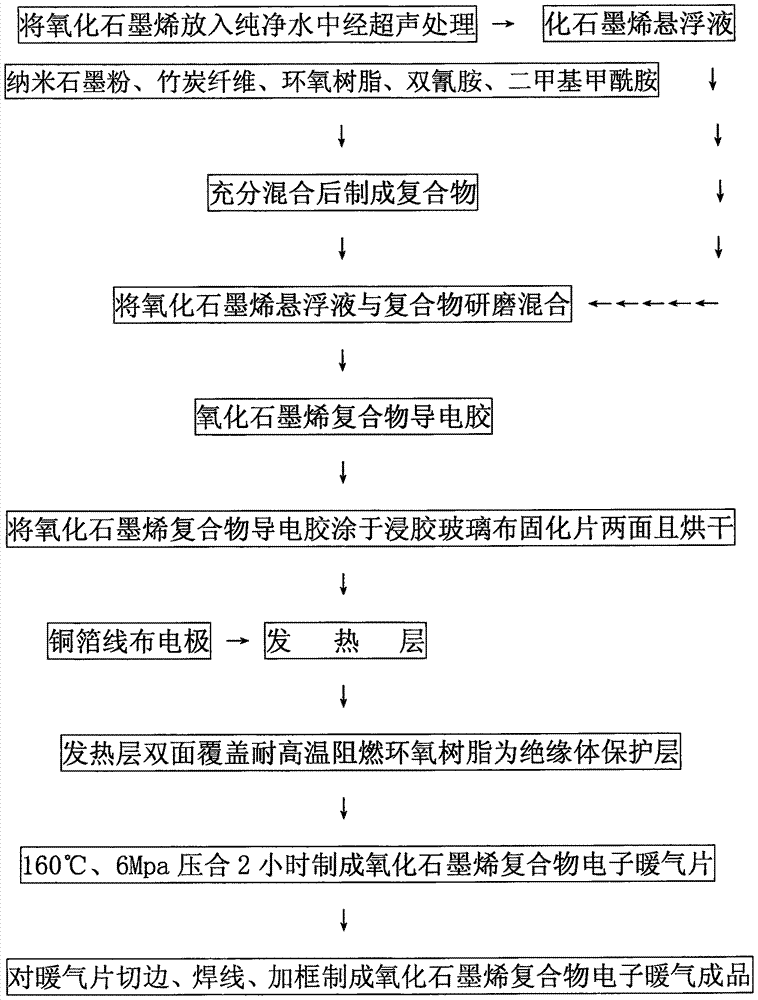

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the accompanying drawings:

[0035]A graphene oxide composite electronic heater is composed of graphene oxide, nano-graphite powder, bamboo charcoal fiber, epoxy resin, dicyandiamide, and dimethylformamide solvent in units of weight;

[0036] ①. Preparation of graphene oxide suspension: put 10 parts by weight of graphene oxide with a purity greater than 95% into 90 parts by weight of pure water, and undergo ultrasonic dispersion treatment to prepare a graphene oxide suspension for use;

[0037] ②, preparation of composite: 55 parts by weight of nano-graphite powder, 15 parts by weight of bamboo charcoal fiber, 18 parts by weight of epoxy resin, 2 parts by weight of dicyandiamide, and 90 parts by weight of dimethylformamide solvent are fully mixed to make a composite reserve;

[0038] ③. Preparation of graphene oxide composite conductive glue: after grindi...

specific Embodiment approach 2

[0046] Carry out by specific embodiment one, just: change parts by weight to gram and carry out implementation, have received the expected good effect.

specific Embodiment approach 3

[0047] Carry out on specific embodiment one, two implementation basis, just: to the consumption of graphene oxide, nano-graphite powder, bamboo charcoal fiber, epoxy resin, dicyandiamide, dimethyl formamide solvent, pure water, respectively to reduce 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 15, 20, 25, and 30 times were implemented, and they were also enlarged by 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 15, 20, 25, and 30 times have been implemented, and all have received the expected good results. The present invention has a solid foundation for small-scale experiments, laboratory tests, enlarged tests, and productive tests, and has the operability of theoretical guidance and production application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com