Underwater docking, recycling and laying device for AUV

A technology for underwater docking and retracting devices, which is applied to underwater ships, underwater operating equipment, transportation and packaging, etc., can solve the problems of AUV body and recovery device damage, poor fit, damage, etc., to reduce damage and The effect of reducing the risk of loss, improving reliability and success rate, and reducing time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

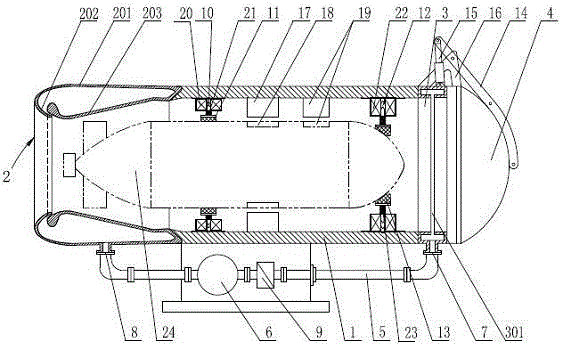

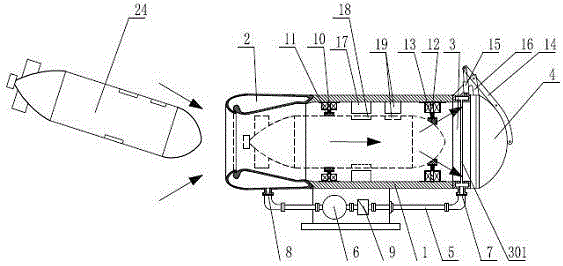

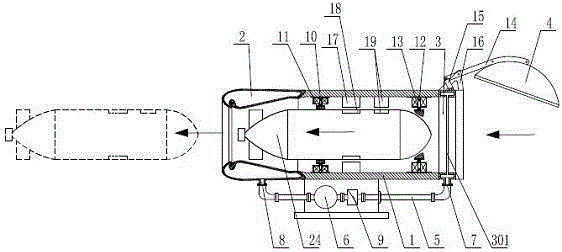

[0023] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0024] See figure 1 , the present invention includes a carrying cylinder 1, the two ends of the carrying cylinder 1 are coaxially fixed with a guide ring 2 and a water pumping ring 3 respectively, and the other end of the water pumping ring 3 is covered with an openable and closable cover body 4; the cover body 4 is used for Cover or open one end of the pumping ring 3, so that the seawater outside the end of the pumping ring 3 connected to the cover 4 can enter the carrying cylinder 1 or be blocked outside the carrying cylinder 1; the ring wall of the guide ring 2 is a hollow shell body, the two ends of the outer wall 201 of the ring wall are respectively bent toward the inside of the guide ring 2 and extend axially along the guide ring 2 to form a throat section 202 and a converging section 203, and the wide mouth end of the converging se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com