Detachable steel container

A steel container and container technology, applied in the field of detachable steel containers, can solve the problems of no painting, a lot of cost and time, and no effective prevention in advance, etc., and achieve the effect of easy disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

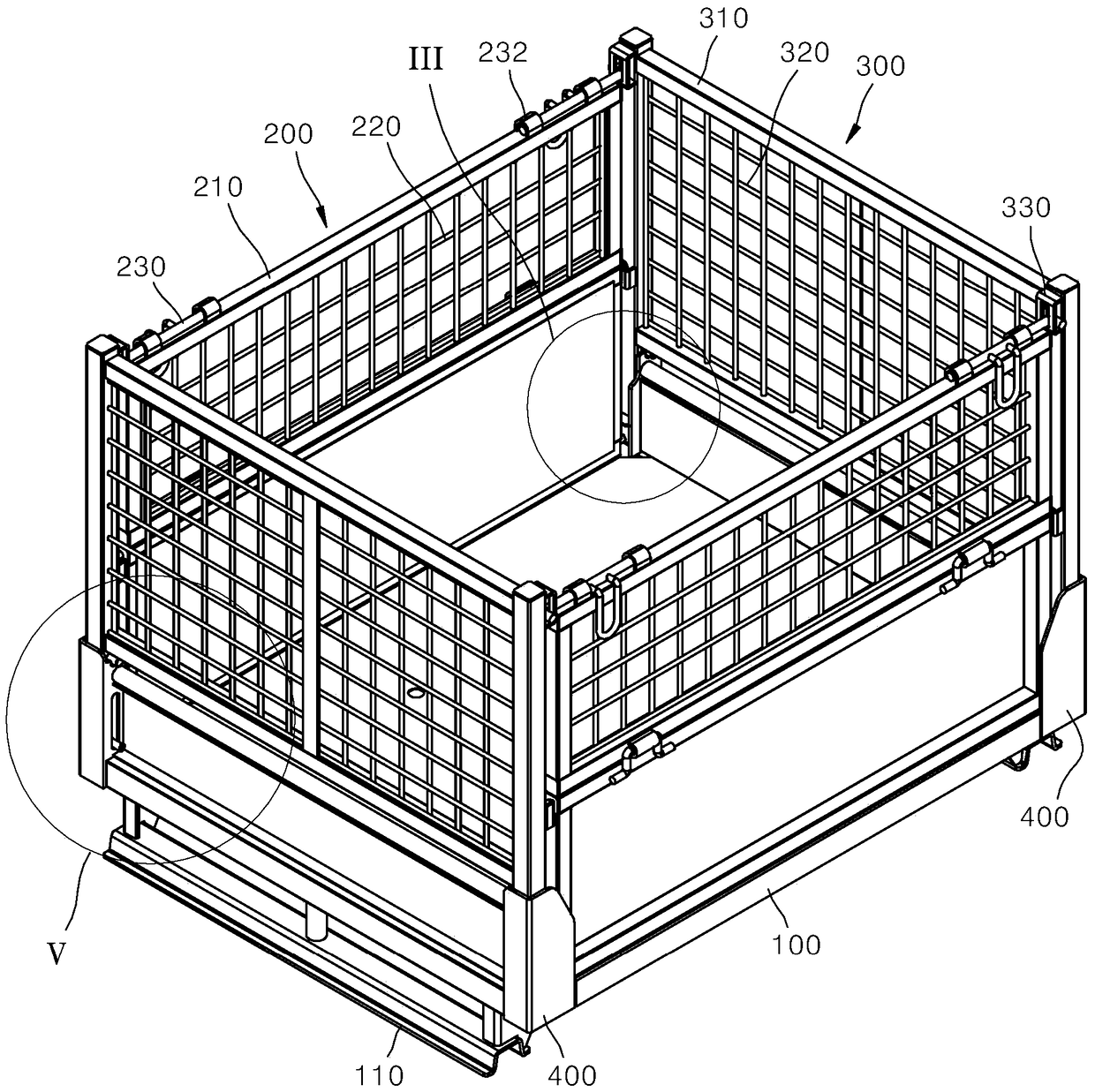

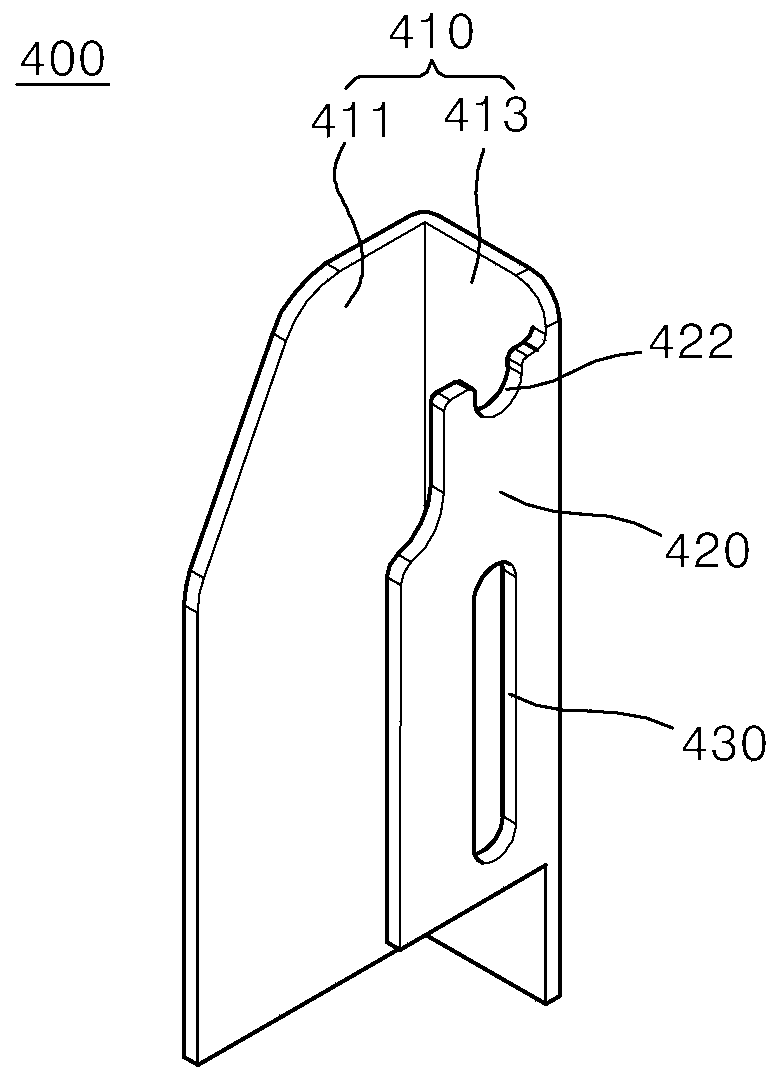

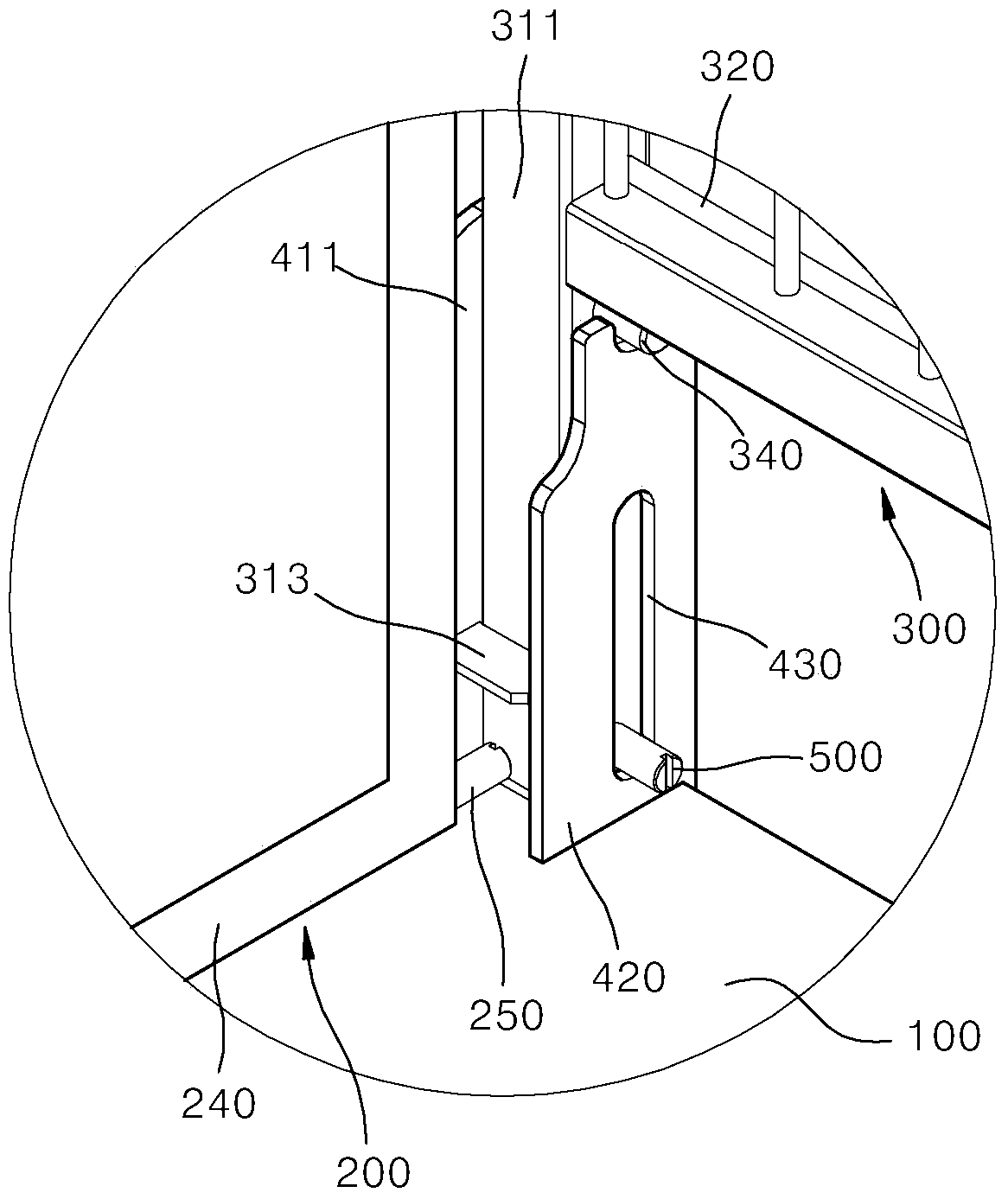

[0053] Hereinafter, embodiments of the present invention will be explained in more detail with reference to the attached drawings. However, the present invention is not limited to the embodiments shown below, but can be embodied in various forms. This embodiment is provided only to fully demonstrate the present invention and enable people with ordinary common sense to fully understand the scope of the present invention. The same symbols on the figures represent the same element.

[0054]The object of the present invention is to provide a steel container that can smoothly load and transport various goods including automobile parts, but is not limited thereto, and is also suitable for transporting parts in various industrial fields including automobiles.

[0055] The steel container of the present invention can be manufactured as one piece or separately as required. In addition, depending on the form of use, some components can be omitted and used as they are.

[0056] Compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com