Four-door elevator

A four-door and elevator technology, which is applied to elevators, lifts, transportation and packaging in buildings to achieve the effects of high structural strength, stable operation and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

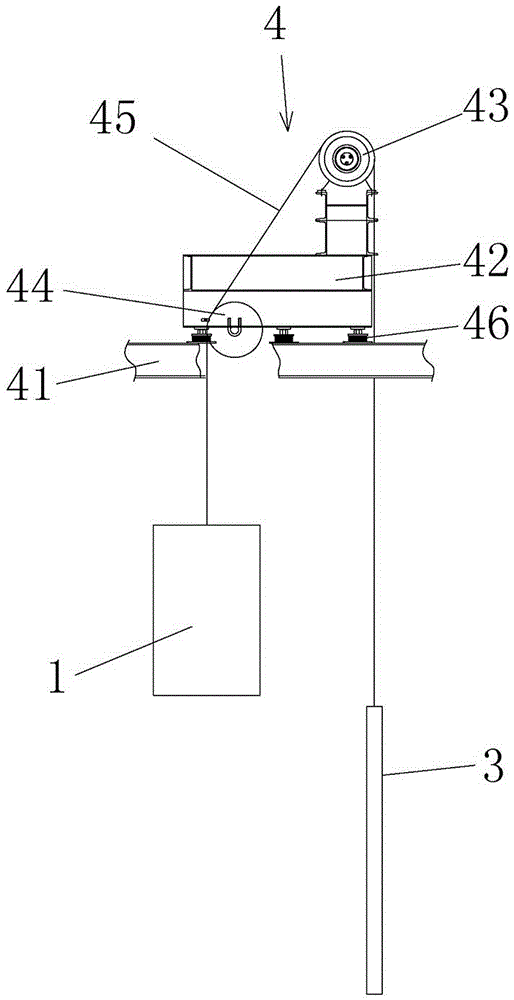

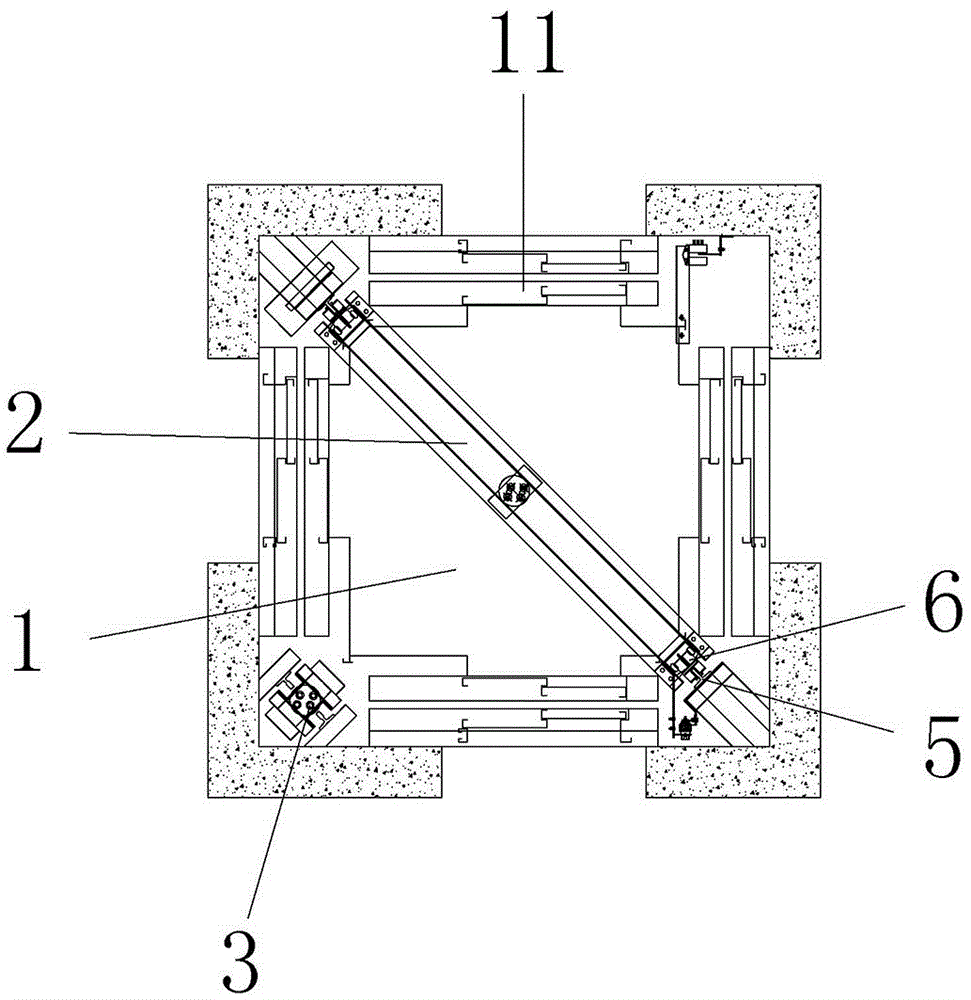

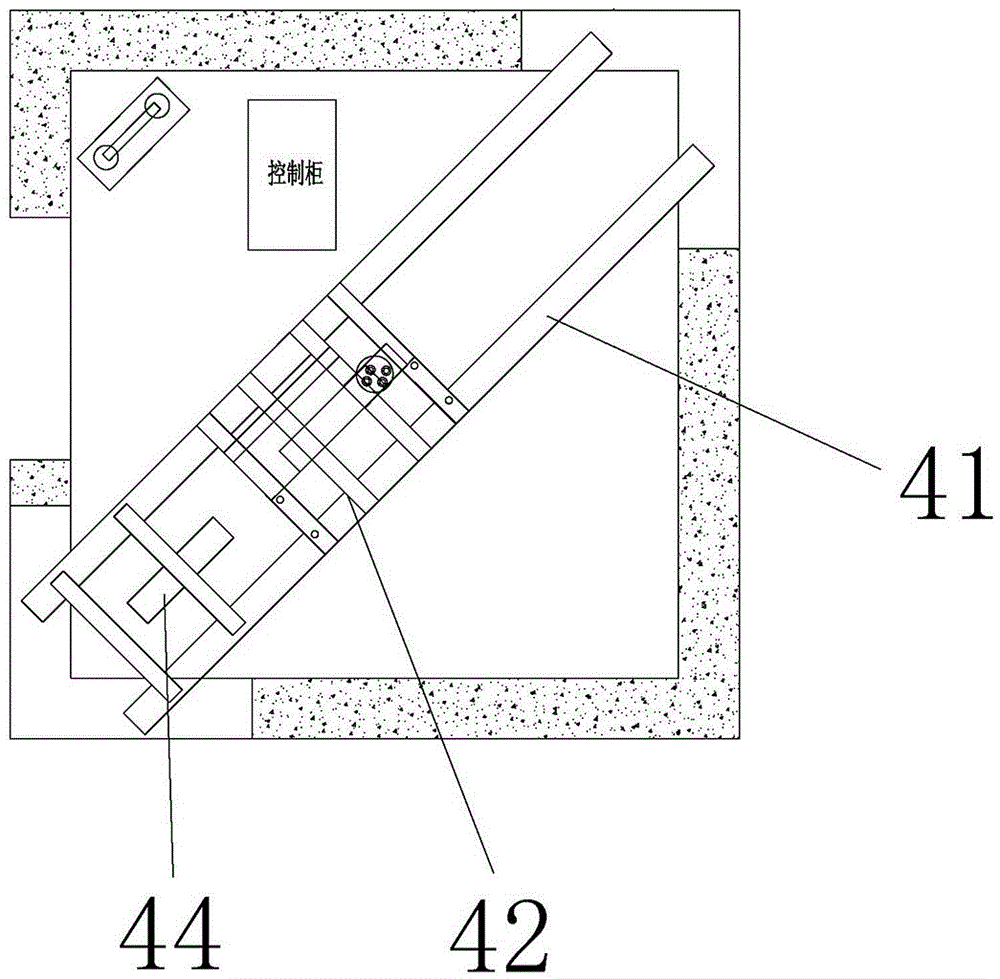

[0029] Embodiment 1: as Figure 1 to Figure 7 As shown, a four-door elevator includes a car, a car frame 2, a car guide rail 5, a counterweight device 3 and a traction device 4. The hoistway is a rectangular structure, and landing doors are arranged around the hoistway. Car doors 11 opposite to the landing doors and door operators that drive the opening and closing of the car doors 11 are respectively provided in the four directions of the horizontal direction, front, rear, left, and right. The car doors 11 adopt conventional side-opening double doors, and the door operators are conventional door operators. . The car wall and the car door are provided with sound insulation cotton, and the well wall of the shaft is provided with a magnetic isolation plate.

[0030] Such as figure 2 and Figure 4 As shown, the car frame 2 includes an upper beam 21, a lower beam 23 and a column 22, and the lower beam 23 is arranged below the car and on the diagonal line of the bottom surface ...

Embodiment 2

[0034] Embodiment 2: as Figure 8 and Figure 9As shown, the difference from Embodiment 1 is that semicircular brackets 24 are provided on both sides of the lower beam 23, and the two brackets 24 form a circle for supporting the car chassis 25. shape support structure. The bracket 24 includes an inner supporting plate 241, an outer supporting plate 243 and a top plate 242, the inner supporting plate 241, the outer supporting plate 243 and the top plate 242 form a C-shaped structure with the opening facing downward, the inner supporting plate 241 and the The outer support plates 243 are provided with round holes 244, and the upper end surface of the top plate 242 is an arc-shaped surface.

[0035] Such as Figure 10 As shown, the end of the bracket 24 is provided with a fixed end 245 for fixing on the lower beam 23, and the two sides of the fixed end 245 are provided with installation parts 2451, and the installation parts 2451 are fixed on the On the lower beam 23, the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com