Deviation rectification and film feeding mechanism for vacuum coating equipment

A vacuum coating machine and film feeding technology, which is applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve problems such as easy vibration, damaged film, complex structure, etc., and achieve easy detection of broken film Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

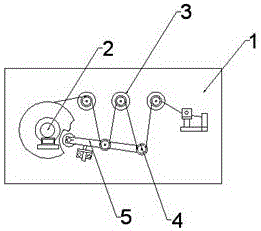

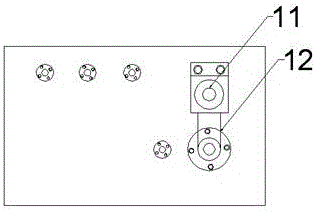

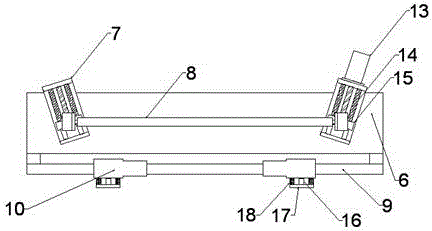

[0019] A vacuum coating machine deflection correction and film feeding mechanism, comprising a mounting plate 1, a film feeding unit and a film deviation correction unit arranged on the mounting plate 1, the film feeding unit includes a film reel 2 for loading a film roll, and drives the film reel 2 to rotate With the first driver for unwinding, some fixed tension rollers 3 and some movable tension rollers 4 arranged on the floating rod 5, one end of the floating rod 5 is hinged on the mounting plate 1, and the other end is a free end, so The movable tension roller 4 is fixed below the midpoint of the line connecting the axes of the two movable tension rollers 4; Two symmetrically arranged bearings 7, between the two bearings 7, a fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com