Suction anchor type overwater piling platform and overwater pile group foundation piling technology

A technology for piling platforms and suction anchors, which can be used in infrastructure engineering, water conservancy projects, artificial islands, etc. It can solve problems affecting construction progress, improve efficiency and quality, reduce offshore operation time, and achieve high piling efficiency and precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

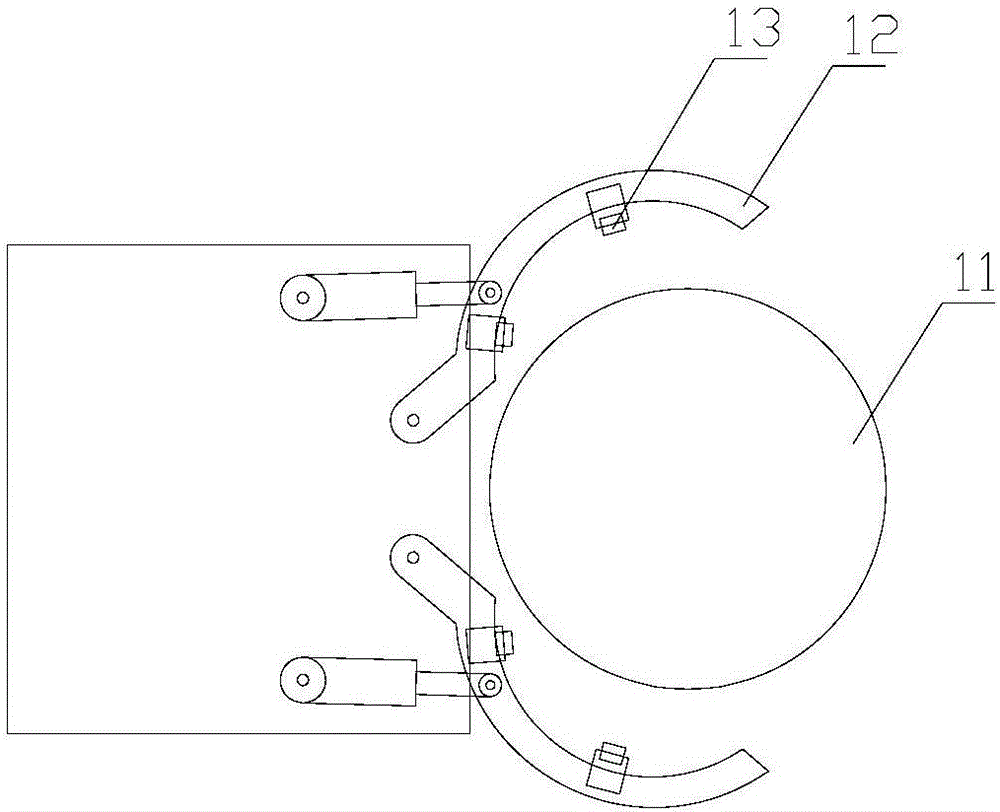

[0055] see attached Figure 4 , the structural features of the inner side of the suction anchored piling platform:

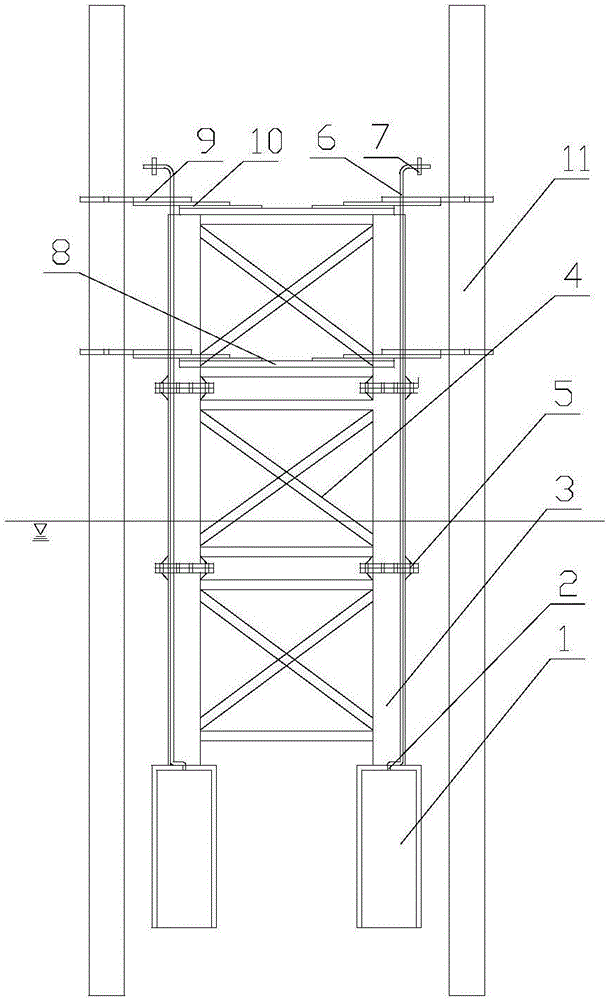

[0056] A suction anchor type water piling platform includes a box tube 1, an exhaust pipe 6, a truss, a guide frame platform, and a pile holder 9. This embodiment also includes four small box tubes 1, and the four truss support rods 3 Connected to four small box tubes 1, the guide frame platform is arranged in two layers and arranged on the top of the truss. The cross section of the guide frame platform is square, and its side length is smaller than the distance between two adjacent truss support rods 3 , the pile holder 9 is installed on the guide frame platform, the pile holder 9 is provided with an openable and closed arm 12, and the arm 12 is provided with a jack 13.

[0057] The suction-anchored floating piling platform of this embodiment can be used to drive a pile group foundation with a smaller radius of the pile group, and its implementation steps are ...

Embodiment 2

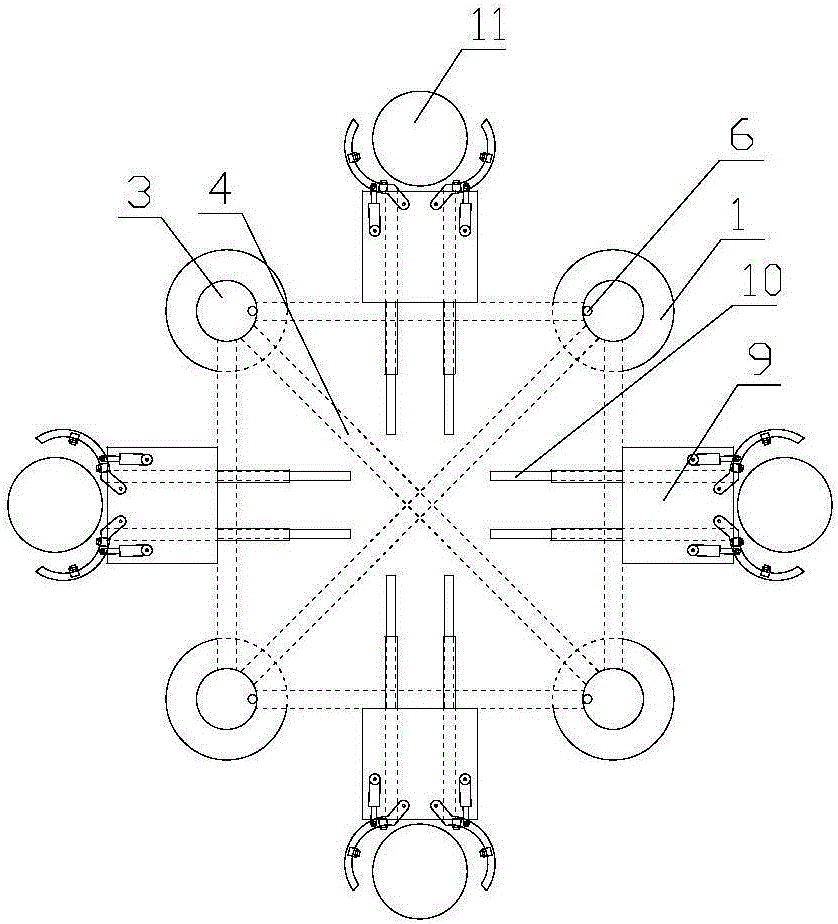

[0059] see attached Figure 5 , the structural characteristics of the six piles driven by the suction anchored piling platform above water:

[0060] A suction anchor type water piling platform includes a box tube 1, an exhaust pipe 6, a truss, a guide frame platform, and a pile holder 9. This embodiment also includes six small box tubes 1, and six truss support rods 3 are connected to six On a small box tube 1, the guide frame platform is arranged in two layers, and is arranged on the top of the truss. The plane shape of the guide frame platform is hexagonal. The pile device 9 is installed on the slideway 10 of the guide frame platform, and the pile holder 9 is provided with an openable and closed arm 12, and the arm 12 is provided with a jack 13.

[0061] The suction anchor type piling platform above water of this embodiment can be used to drive a pile group foundation of six piles, and its implementation steps are the same as the above-mentioned specific process steps. . ...

Embodiment 3

[0063] see attached Figure 6 , the structural characteristics of the three piles driven by the suction anchored piling platform above water:

[0064] A suction anchor type water piling platform includes a box tube 1, an exhaust pipe 6, a truss, a guide frame platform, and a pile holder 9. This embodiment also includes four small box tubes 1, and four truss support rods 3 are connected to the On the four small box tubes 1, the guide frame platform is arranged in two layers and is arranged on the top of the truss. The planar shape of the guide frame platform is a square, and its side length is the same as the distance between two adjacent truss support rods 3. The guide frame platform is arranged with guide frame platform slideways 10 along its three sides, and the described pile holder 9 is installed on the guide frame platform slideway 10, and the described pile holder 9 is provided with arms that can be opened and closed. 12. The arm 12 is provided with a jack 13 .

[0065...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap