Oil and gas well production increasing method

A technology for oil and gas wells and near-wellbore, which is applied in earth-moving drilling, wellbore/well components, and production fluids, etc. It can solve the problems of near-wellbore fracture conductivity loss, high cost and high risk, and improve and restore fracture conductivity. Flow capability, simple method, effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

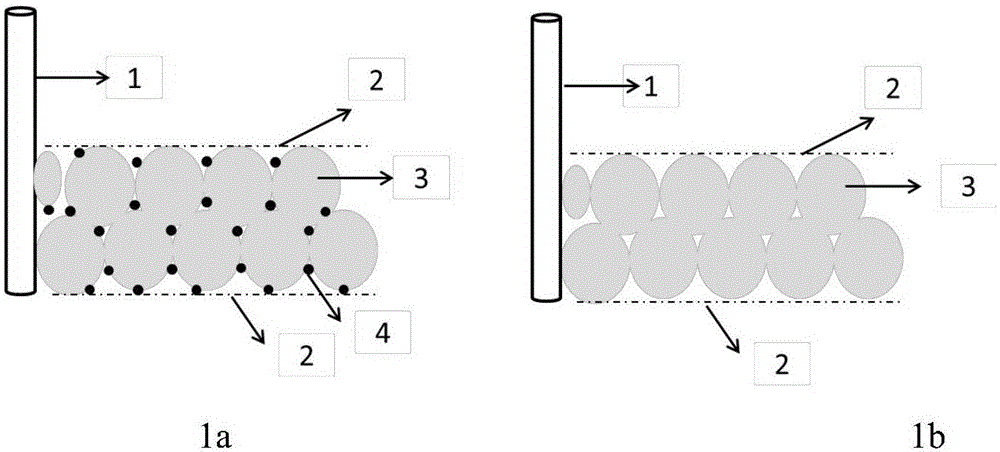

[0033] like figure 1 As shown, the fractures formed by fracturing are filled with muddy pollutants, resulting in low overall conductivity and a fluid production rate of 1.5 cubic meters per day. Under the premise that the cracks do not open, with a displacement of 0.3 cubic meters per minute, squeeze 12wt% of hydrogen chloride, 3wt% of hydrogen fluoride, 1wt% of corrosion inhibitor (SRCI-2), and 1wt% of iron ions into the soil acid solution to stabilize Clay stabilizer (SRFS-1) and 1wt% clay stabilizer (SRCS-2), the dosage is 1 times the volume of the fracture, that is, 12 cubic meters. The clay acid solution has low viscosity and can quickly distribute acid in the entire range of cracks.

[0034] After the dissolution of muddy pollutants is removed, the diversion capacity increases, and the liquid production rate increases to 6.0 cubic meters per day.

Embodiment 2

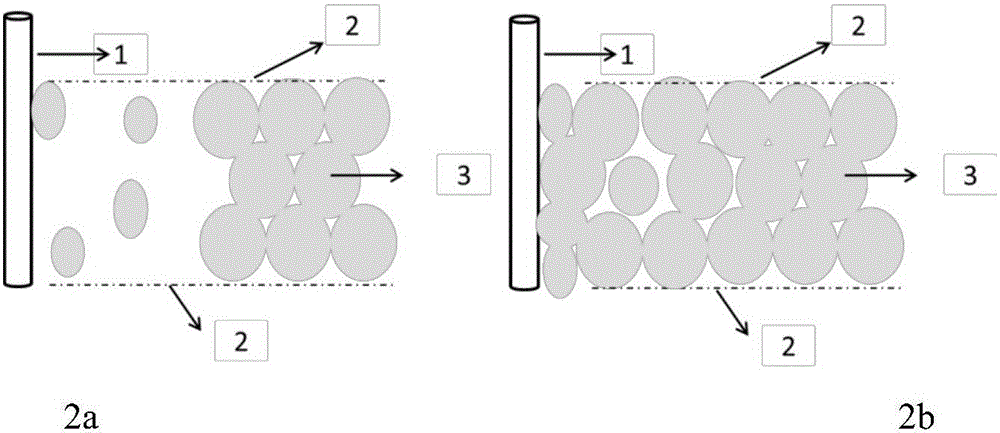

[0036] like figure 2 As shown, the first fracturing had a low conductivity of near-wellbore fractures due to over-displacement of 5 cubic meters, and the fluid production rate was 2.1 cubic meters per day. Use 2 cement trucks with a displacement of 2.3 cubic meters per minute to inject active water (dosage is 2 times the volume of the fracture, 10 cubic meters) to allow the cracks to open quickly. Stop the pump immediately and take the wellhead blowout for a total of 15 cubic meters. The proppant flowed back in the fracture, the support near the wellbore was good, the conductivity was restored, and the fluid production increased to 6.8 cubic meters per day.

Embodiment 3

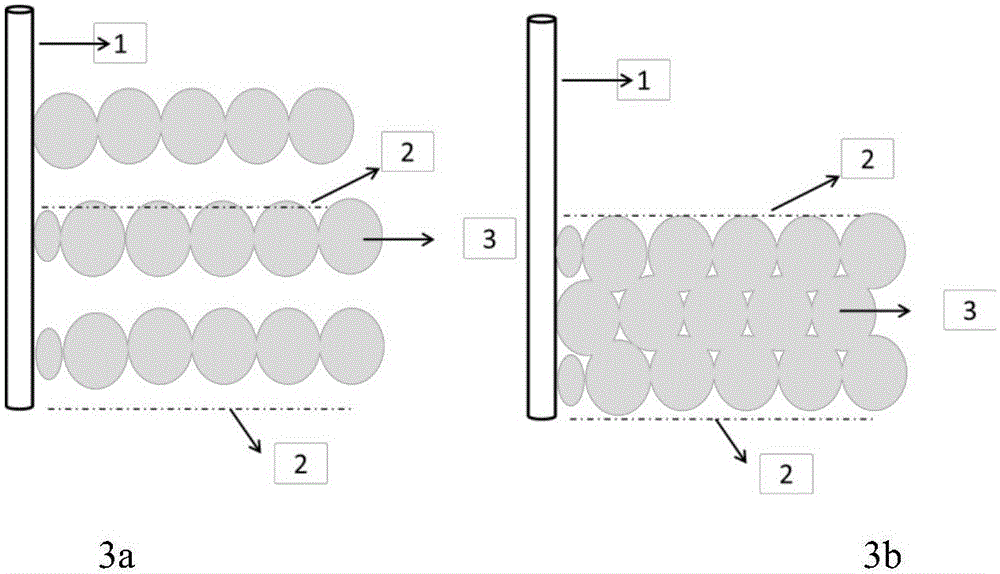

[0038] like image 3 As shown, the fracture height of the first fracturing was out of control, part of the proppant did not play a role in the reservoir, and the fluid production rate was 2.8 cubic meters per day. Use 2 cement trucks with a displacement of 2.2 cubic meters per minute to inject active water (3 times the volume of the fracture, 15 cubic meters) to allow the fracture to open quickly, stop the pump immediately and wait for the proppant to settle for 25 minutes before opening the well and blowing out 2 squares of liquid. The proppant in the upper part of the reservoir flowed back, the fracture conductivity in the reservoir increased, and the liquid production rate increased to 8.0 cubic meters per day.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com