Yield-increasing foam discharging agent as well as preparation method and application thereof

A technology of foaming agent and initiator, which is applied in chemical instruments and methods, earth square drilling, mining fluids, etc. It can solve the problems of poor foam removal effect and insufficient liquid carrying capacity of foam removal rods, and achieve increased production, easy purchase and Transport, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] The present invention also provides a kind of preparation method of increasing production defoaming agent, comprises the following steps:

[0075]Preparation of the first foam removal rod: mix the ammonium salt and the first surfactant uniformly according to the above ratio, put it into a conventional cylindrical stainless steel mold, press it into a rod by a pressure of more than 20 tons, and obtain the first foam removal rod;

[0076] Preparation of the second foam removal rod: mix the nitrite and the second surfactant evenly according to the above ratio, put it into a conventional cylindrical stainless steel mold, press it into a rod by a pressure of more than 20 tons, and obtain the second foam removal rod ;

[0077] Preparation of the trigger rod: After mixing the solid acid and the third surfactant uniformly according to the above ratio, put it into a conventional cylindrical stainless steel mold, and press it into a rod by a pressure of more than 20 tons to obtai...

Embodiment 1

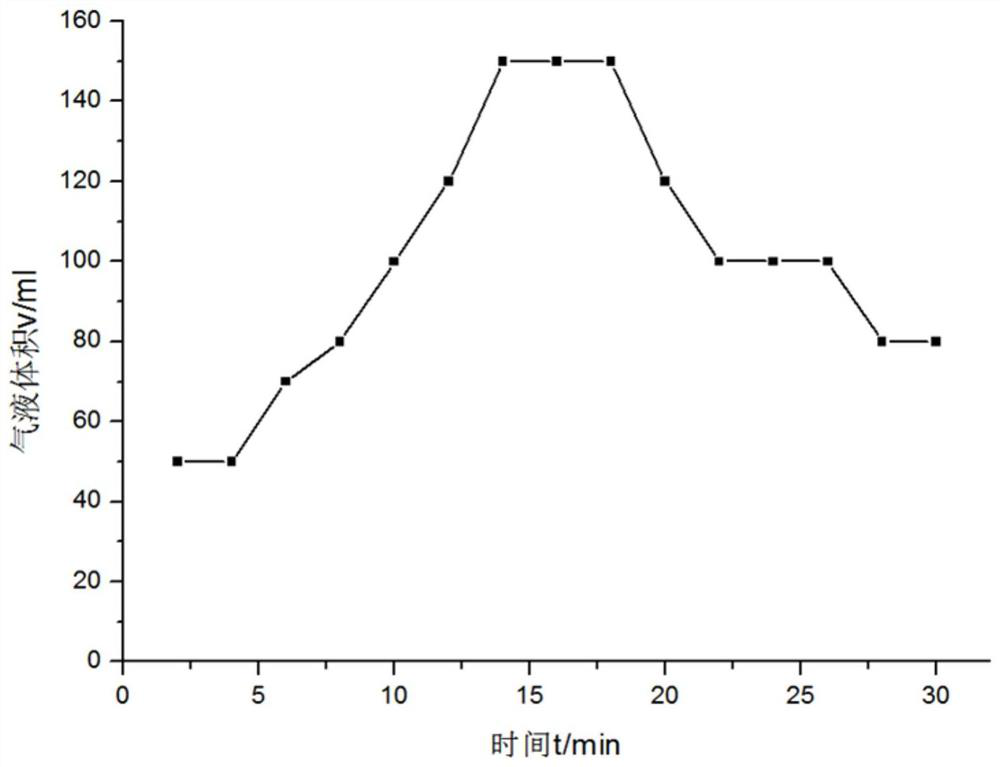

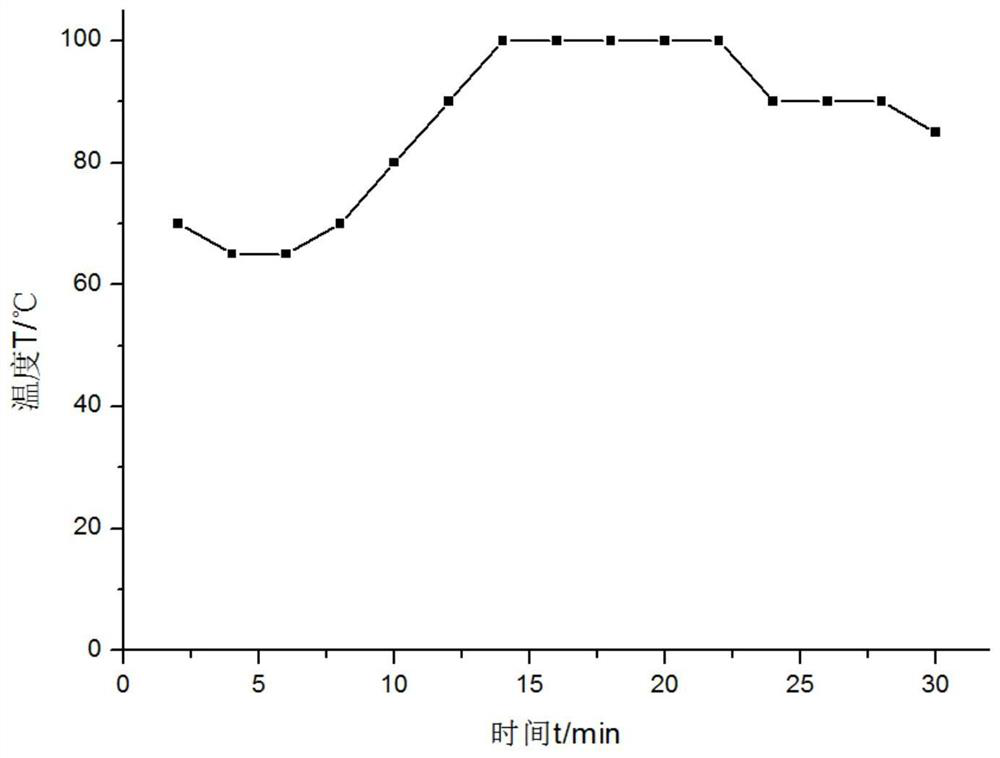

[0088] 12g of ammonium chloride and 3g of sodium dodecylbenzenesulfonate were mixed uniformly, put into a stainless steel cylindrical mold and pressed into a first bubble removal rod with a diameter of 2.5cm. Mix 16g of sodium nitrite and 4g of sodium dodecylbenzene sulfonate evenly, put it into a stainless steel cylindrical mold and press it into a second foam removal rod with a diameter of 2.5cm; put the first foam removal rod and the second foam removal rod into a 100mL graduated cylinder, measure 40ml of hot water at 80°C, and pour it into the graduated cylinder. The first foam row rod and the second foam row rod dissolve, and the reaction generates a large amount of gas and heat. The reaction is very violent. After 14 minutes, foam rushes out of the measuring cylinder. The relationship between the volume of the gas-liquid mixture in the measuring cylinder and the time is as follows: figure 1 As shown, the relationship between the temperature and time of the gas-liquid mix...

Embodiment 2

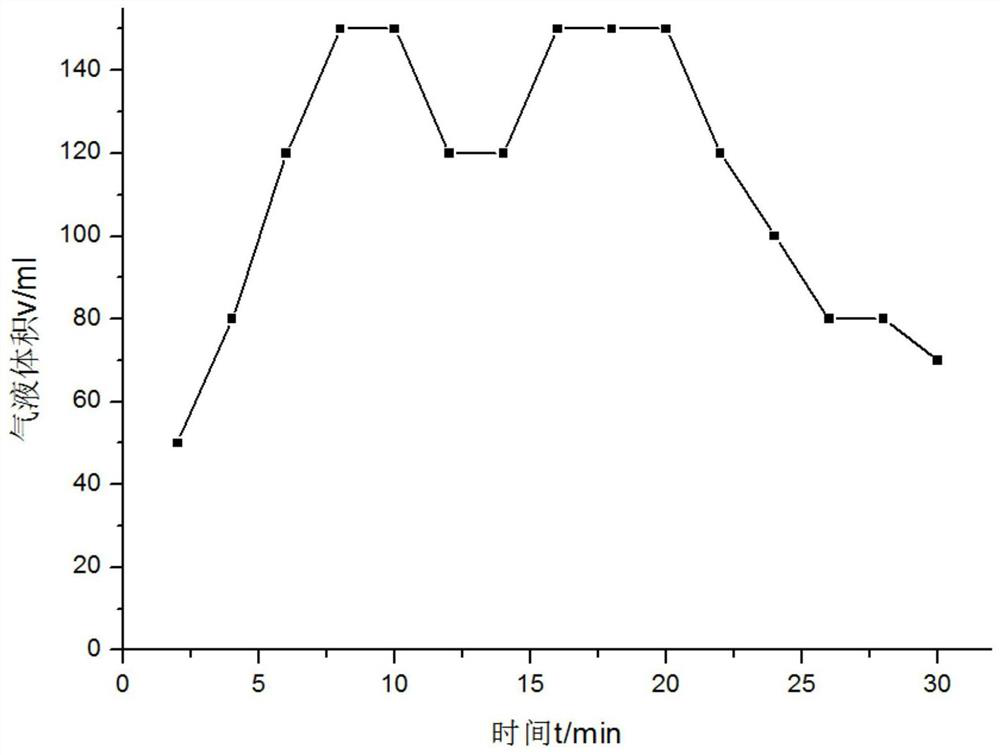

[0090] 12g of ammonium chloride and 3g of sodium dodecylbenzenesulfonate were mixed uniformly, put into a stainless steel cylindrical mold and pressed into a first bubble removal rod with a diameter of 2.5cm. Mix 16g sodium nitrite and 4g sodium dodecylbenzene sulfonate evenly, put it into a stainless steel cylindrical mold and press it into a second foam removal rod with a diameter of 2.5cm; mix 1g sulfamic acid and 0.3g dodecylbenzene The sodium sulfonate is mixed evenly, put into a stainless steel cylindrical mold and press to form an initiator rod with a diameter of 2.5 cm. Put the first foam removal rod and the second foam removal rod into a 100mL measuring cylinder, measure 40ml of water at 40°C, pour it into the measuring cylinder, the foam removal rod dissolves slowly in the measuring cylinder, no gas is generated, and no heat is released. After 1 minute, take the trigger rod and put it into the graduated cylinder, the solution in the graduated cylinder reacts violentl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com