Shaft assembly

A technology of shaft assembly and assembly, applied in the direction of bearing elements, shafts, crankshafts, etc., can solve the problems of time-consuming, expensive surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

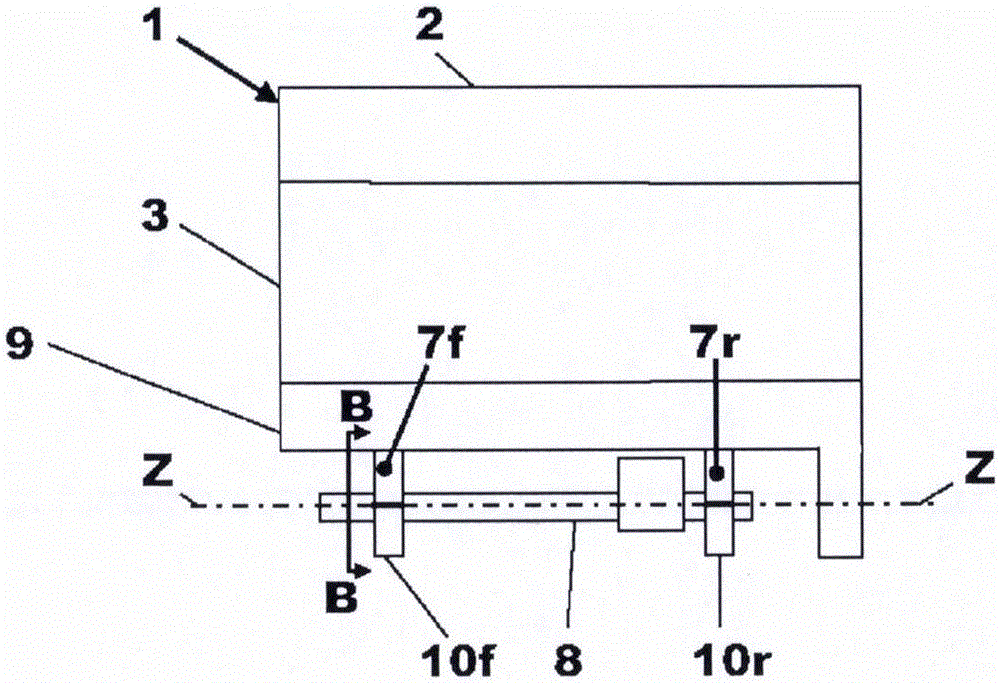

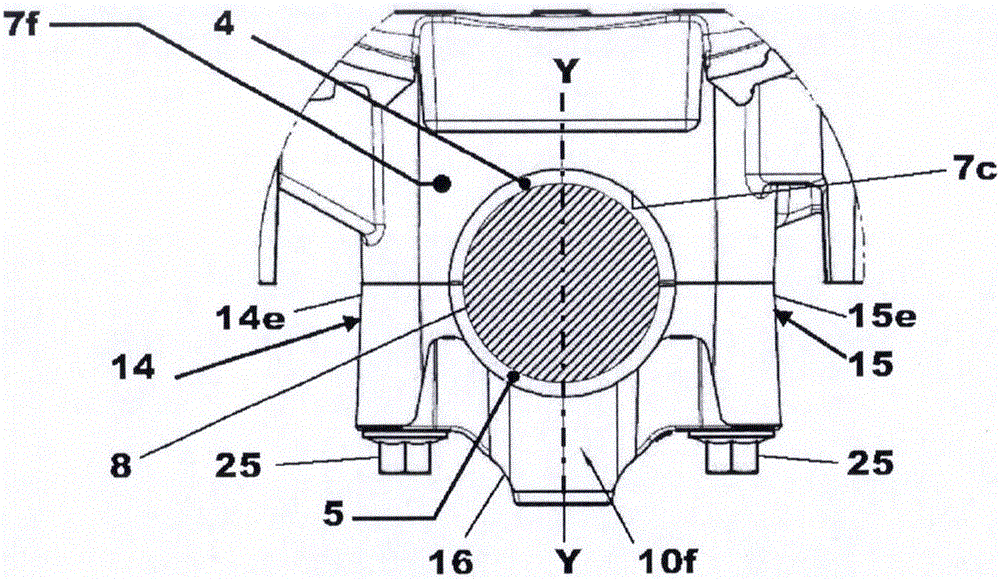

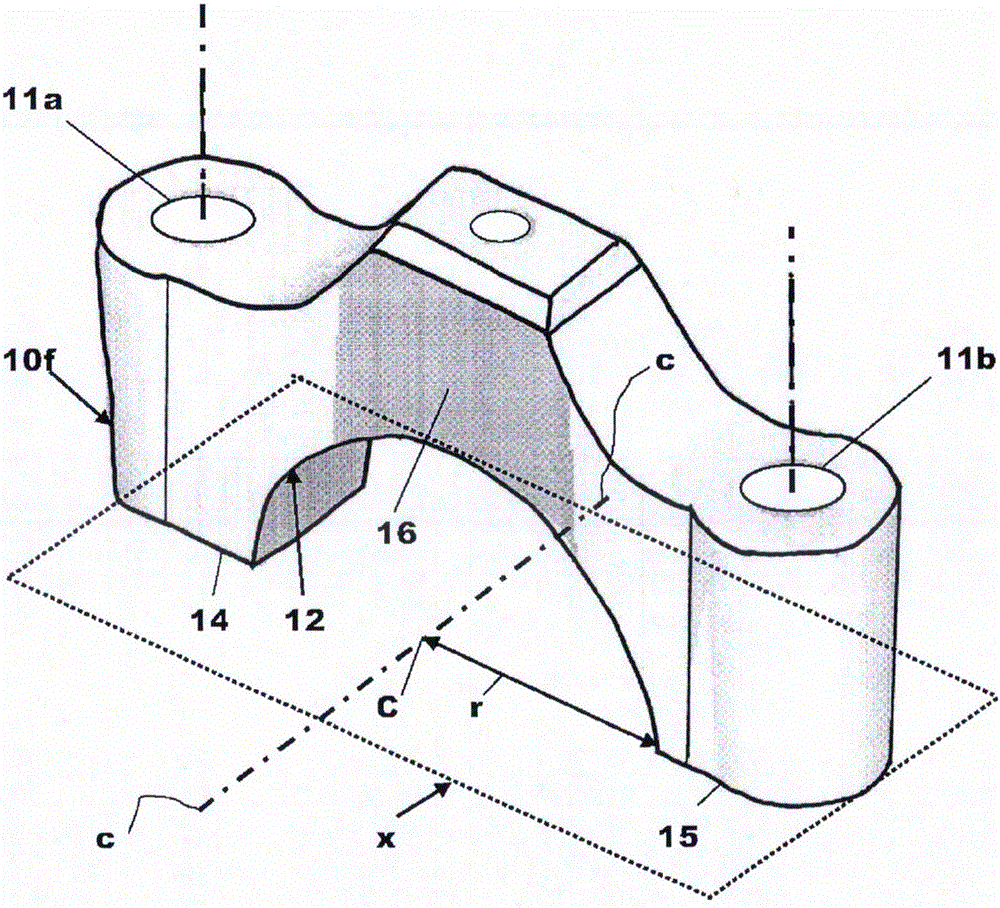

[0046] specific reference Figure 1a , Figure 1b , figure 2 and image 3 , shows an engine 1 having a cylinder head 2 , a cylinder block 3 and a trapezoidal frame 9 bolted to the lower end of the cylinder block 3 . The trapezoidal frame 9 defines at the lower end a front bearing support structure 7f and a rear bearing support structure 7r, to each of which a respective error proof bearing cap 10f, 10r is bolted by a pair of bolts 25 . The front bearing cap 10f is bolted to the front bearing support structure 7f and the rear bearing cap 10r is bolted to the rear bearing support structure 7r.

[0047] In the exemplary case where the shaft 8 is an engine balancer shaft, the shaft 8 is rotatably supported by the front bearing cap 10f and the rear bearing cap 10r and the front bearing support structure 7f and the rear bearing support structure 7r to form a shaft and bearing assembly. In the example case, the shaft 8 is rotatably supported by two bearing support assemblies 7f, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com