Self-tapping screw

A self-tapping screw and screw body technology, applied in the direction of screws, nuts, bolts, etc., can solve the problems of potential safety hazards, impact on service life, high cost, etc., achieve significant anti-slip effects, increase service life, and prevent rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

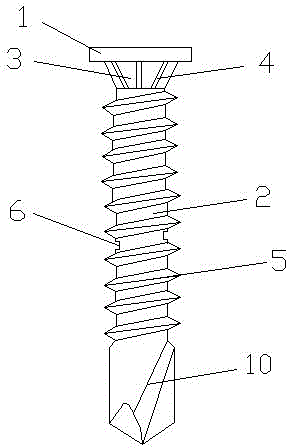

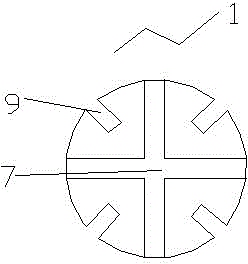

[0017] Such as figure 1 with 2 As shown, a self-tapping screw of the present invention includes a screw body, the screw body includes a nut 1 and a screw 2 at its bottom end. The screw 2 is provided with a thread 5, and the end of the screw 2 has a taper-shaped self-tapping end 3. Between the nut 1 and the screw 2 is a cone-shaped cylindrical section 3. The diameter of the small end of the cone-shaped cylindrical section 3 is the same as the diameter of the screw 2, and the diameter of the large end of the cone-shaped cylindrical section 3 is smaller than the diameter of the nut 1. The circumferential surface of the section 3 is provided with a plurality of elongated convex teeth 4, and the elongated convex teeth 4 are arranged at intervals. The two threads on the screw 2 near the self-tapping end 10 are provided with grooves 6, grooves 6 Around the screw 2 times. A cross groove 7 is formed on the upper end surface of the nut 1, and two or more rectangular opening grooves 9 are...

Embodiment 2

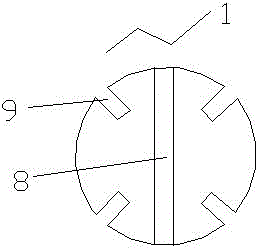

[0019] Such as figure 1 with 3 As shown, a self-tapping screw of the present invention has a groove 8 formed on the upper end surface of the nut 1, and the rest of the structure is the same as the first embodiment.

[0020] The self-tapping screw of the present invention has simple processing and simple assembly, and the plurality of elongated convex teeth 4 provided on the circumferential surface of the tapered cylindrical section 3 has a remarkable anti-slip effect. The groove 6 around the screw 2 is arranged between the two threads on the screw 2 close to the self-tapping end 10, which can easily be hit with a heavy object to break the self-tapping screw at the position where the groove is provided, thereby effectively preventing it The exposed part is rusty, which increases the service life of the screw and avoids or reduces the possible harm to the human body from the exposed part. There are also two or more rectangular opening grooves 9 formed on the upper end surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com