Coal-fired boiler energy efficiency on-line monitoring method based on chemical balance

A technology for coal-fired boilers and energy efficiency, applied in the testing of machines/structural components, measuring devices, instruments, etc., can solve problems such as inaccurate energy efficiency data and inability to realize online monitoring of boilers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

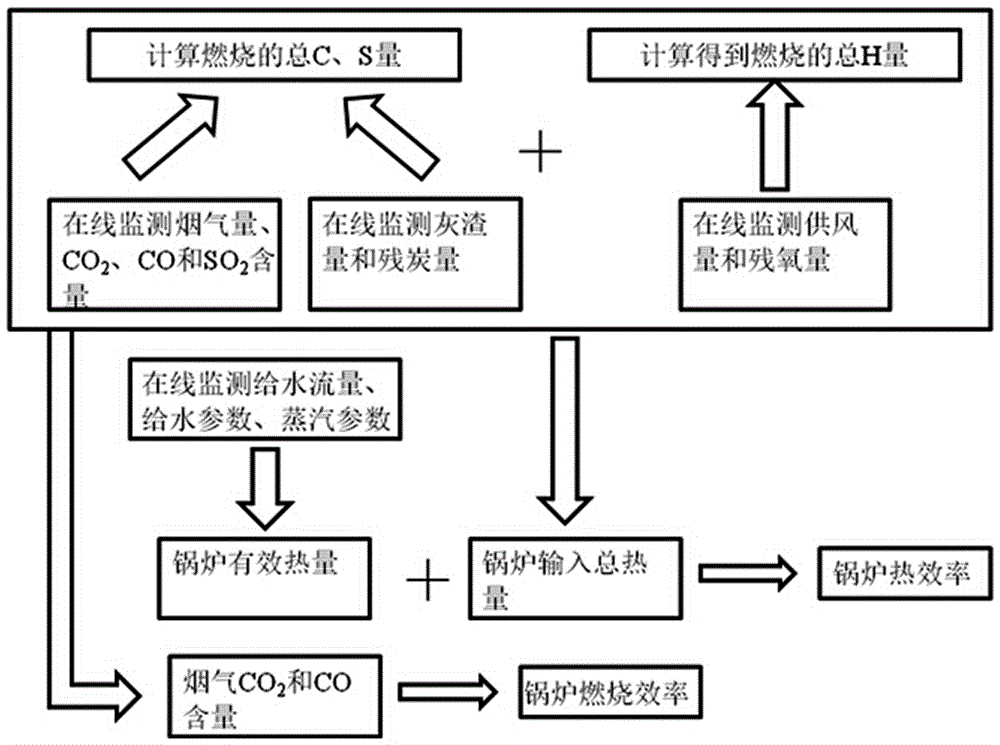

[0023] Further illustrate the present invention below in conjunction with accompanying drawing.

[0024] The present invention realizes the real-time monitoring of the thermal efficiency of the coal-fired boiler operation, and all the data are obtained through online real-time testing, which accurately reflects the real-time energy efficiency level of the boiler. The specific process is as follows: figure 1 shown.

[0025] For coal-fired industrial boilers, using the traditional positive balance method, the reason why the thermal efficiency of the boiler cannot be monitored in real time is that the type of coal used by the boiler changes a lot, and the calorific value of the coal cannot be monitored online, so the input to the boiler cannot be measured online. total calories. For the coal combustion process, the heat released by the combustion of C and H in coal accounts for more than 99% of the total combustion heat. Therefore, according to the monitoring of parameters such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com