Pressure measuring method for spiral welded steel pipe with reinforcing ring

A technology of spiral steel pipe and reinforcing ring, which is used in the test of fluid tightness, the test of machine/structural components, the use of stable tension/pressure to test the strength of materials, etc. problems, to reduce waste, improve production efficiency, and achieve the effect of high operational flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

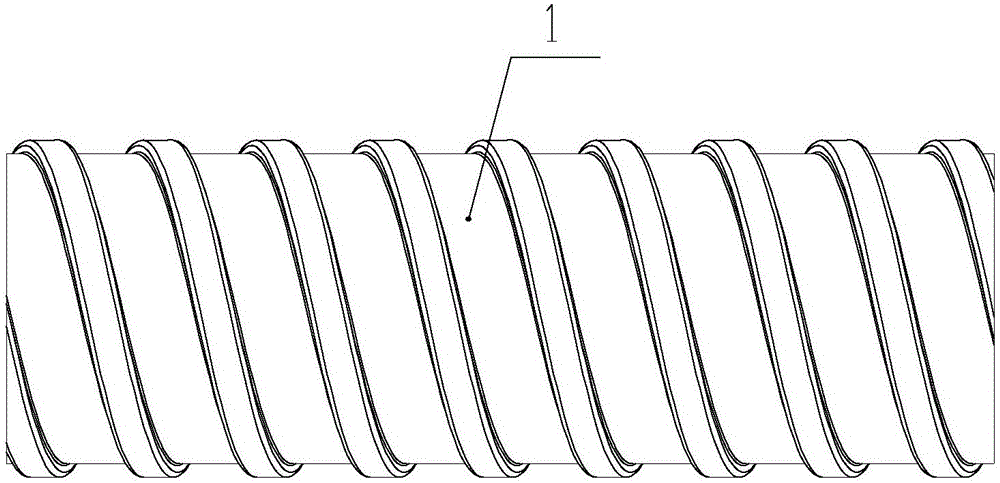

[0022] Such as figure 1 , Figure 9 As shown, a pressure measurement method for a spiral steel pipe with a reinforcing ring includes the following steps:

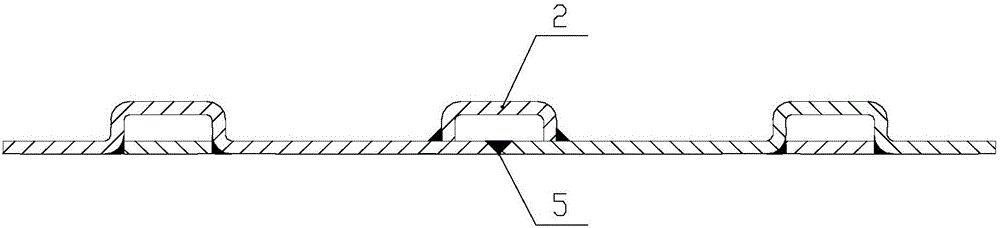

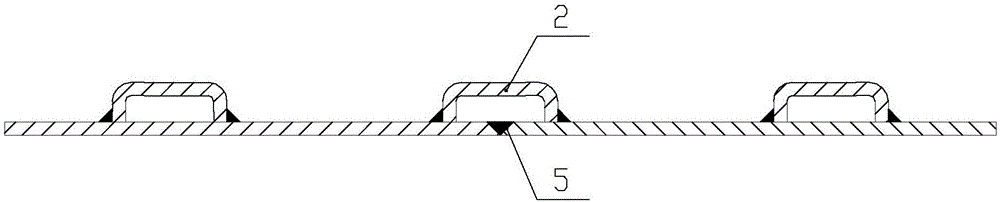

[0023] First, the two ends of the tested reinforcing ring 2 on the spiral steel pipe 1 with the reinforcing ring are blocked, and the ends of the tested reinforcing ring 2 are blocked by the blocking plate 6, as Figure 4 and Figure 5 shown.

[0024] Next, install the pressure gauge 3 and the filling port 4 on the spiral steel pipe 1, and communicate with the inside of the reinforced ring 2 to be tested. The filling port 4 is connected to the filling equipment, and the filling device 7 is used to fill the filling port 4 with liquid or gas. , and form a certain pressure, stop pouring to see if the air pressure of pressure gauge 3 drops, if the air pressure drops, the quality of the weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com