A high-density optical fiber distribution box

A junction box, high-density technology, used in optics, light guides, optical components, etc., can solve the problems of occupying limited space in cabinets, low density of fiber optic junction boxes, inconvenient operation, etc. The effect of reducing the space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

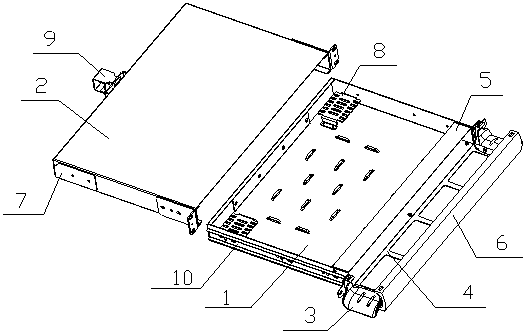

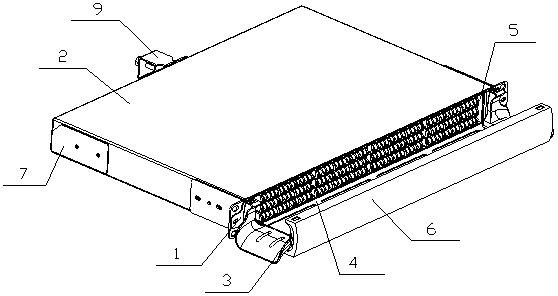

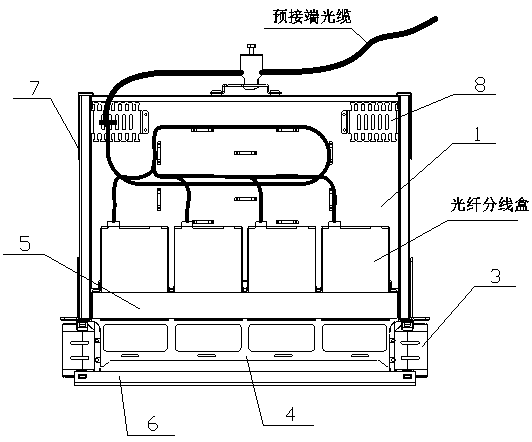

[0023] Referring to the drawings, a high-density optical fiber distribution box, its structure includes a box body 1, a box cover 2, a wire clamp ring 3, a cable management tray 4, a mounting plate 5, a face cover 6, a cable inlet baffle 7, a fixing plate 8. Optical cable fixing assembly 9, guide rail 10; wherein the mounting plate 5 is fixed in the box body 1 with screws through the a hole 1-1 on the box body 1. The mounting plate 5 can be installed in a variety of end methods and different Type of fiber optic module box, and expandable, up to 144 cores; use screws to fix the cable management tray 4 on the mounting plate 5 through the b hole 5-1 on the mounting plate 5, and fix the c hole on the mounting plate 5 5-2 The fixing screws are removed, and the cable management tray 4 can be turned into the box body 1, thereby saving space during product transportation and improving the packaging strength; the box body 1 and the box cover 2 can slide through the guide rail 10.

[0024]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com