Fireproof protection method for cable connector used in humid environment

A technology for cable joints and humid environments, applied in cable joints, fire rescue, etc., can solve problems such as heat accumulation, explosion, unfavorable cable operation safety, etc., and achieve the effect of reducing explosion or fire accidents and facilitating heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

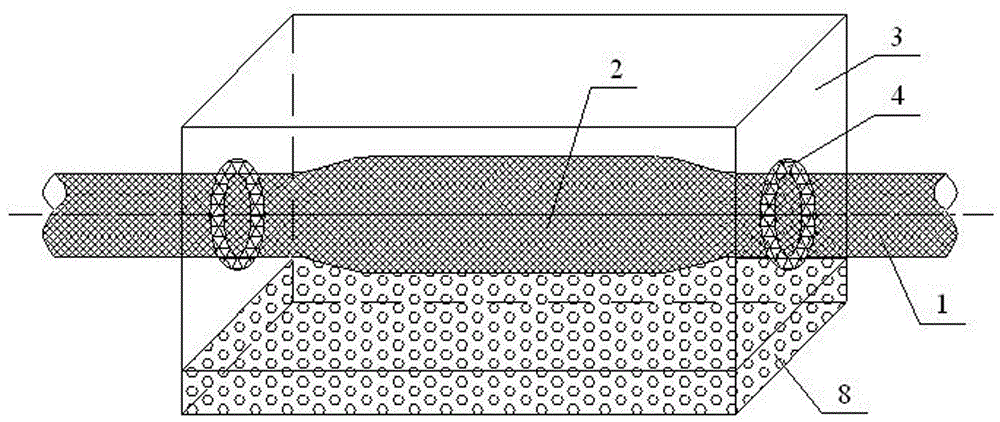

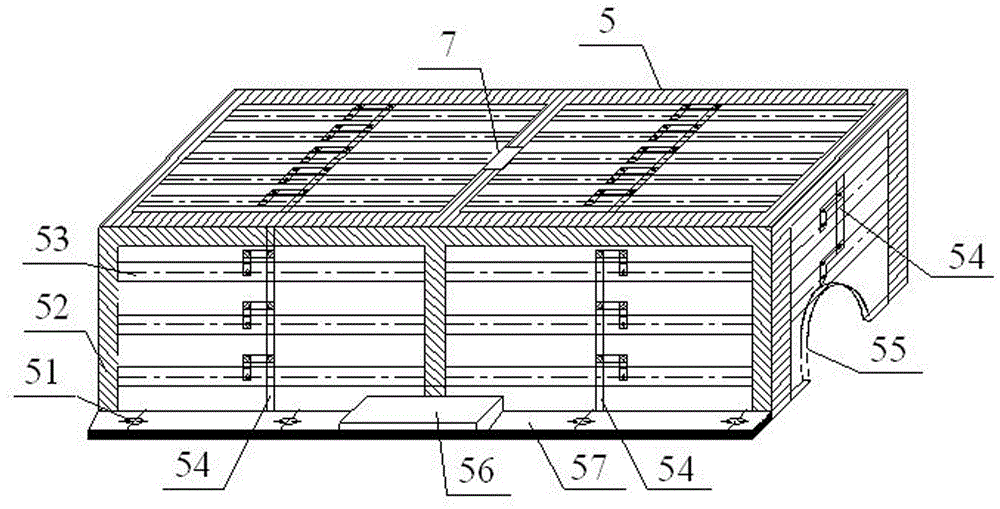

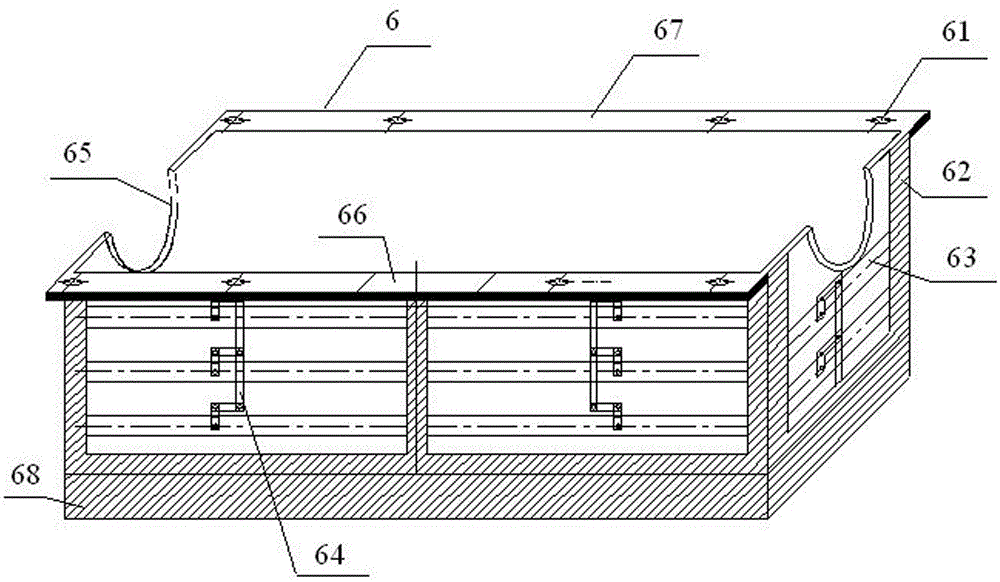

[0027] A fireproof protection method for cable joints used in humid environments provided by the present invention is realized by using a fireproof protection box for cable joints used in humid environments, such as figure 1 As shown, it has a cavity inside to accommodate the cable joint 2; the bottom of the fire protection box 3 is provided with a non-combustible dehumidification material 8; The temperature and humidity sensor 7 connected by communication with the moisture-proof, fire-proof and heat-dissipating components; the fire protection method includes:

[0028] The temperature and humidity sensor 7 detects the real-time temperature in the fire protection box 3, and judges whether it exceeds the preset warning value;

[0029] When it is detected that the real-time temperature in the fire protection box 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com