A kind of multi-core layer inorganic mineral insulated flexible fireproof cable and preparation method thereof

A technology of inorganic minerals and fireproof cables, which is used in the manufacture of insulated cables, inorganic insulators, cables/conductors, etc., can solve the problems of inability to discharge the rubber mixing box, the influence of the operating environment, and the long mixing time, and achieves thermal stability and Excellent mechanical properties, ensure safe operation, good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

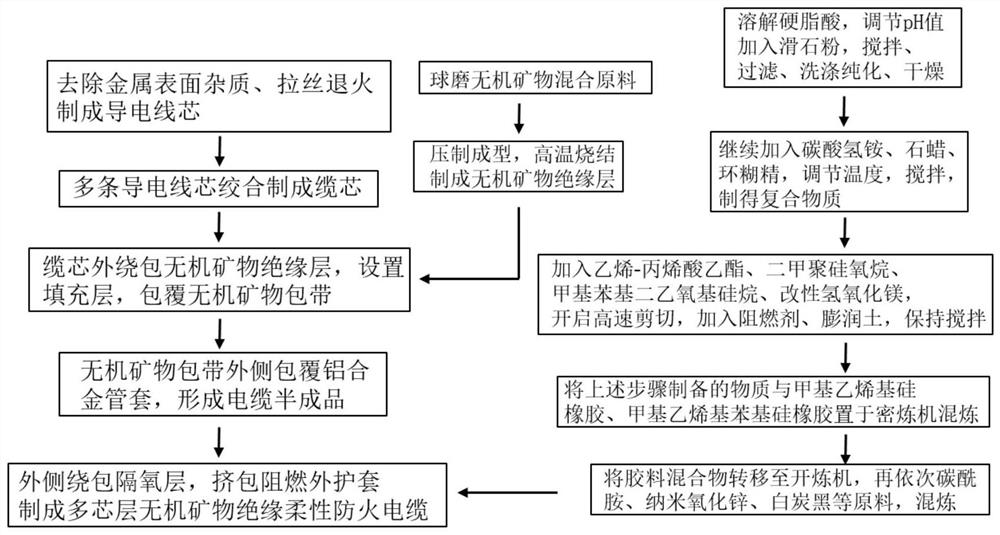

[0105]S1. Remove impurities on the metal surface, straighten after drying, wire drawing and annealing to make a conductive wire core,

[0106] A plurality of conductive wire cores are twisted to form a cable core;

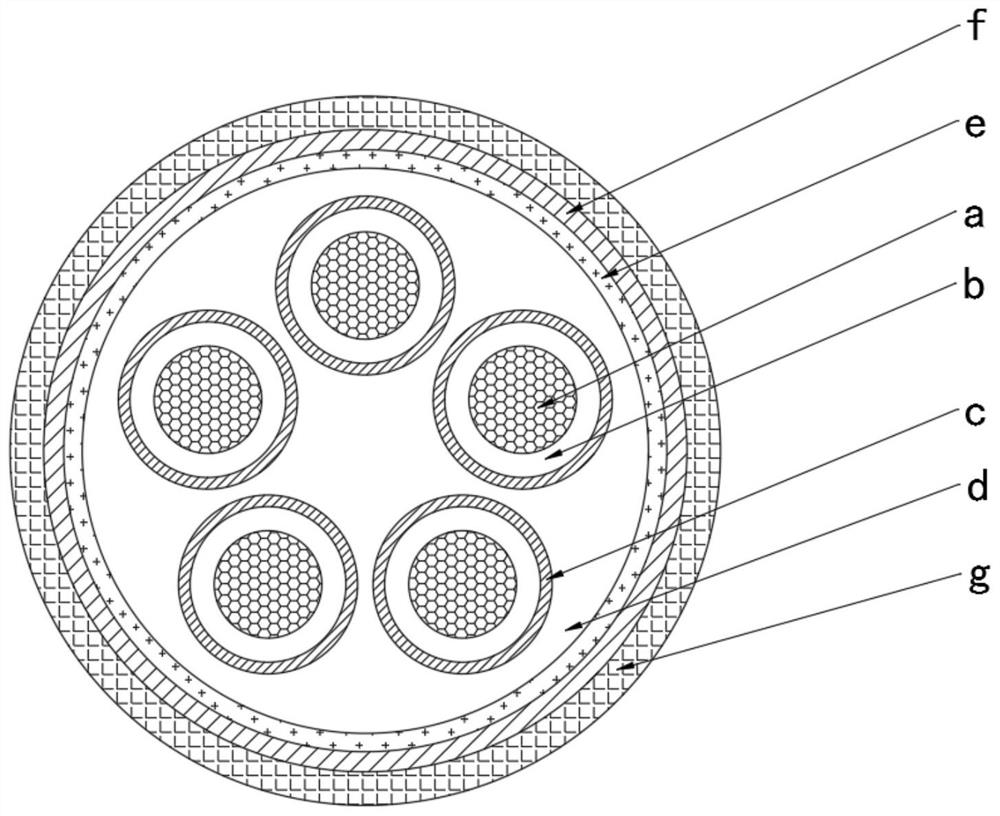

[0107] S2. Wrap an inorganic mineral insulating layer around the cable core, set a filling layer between multiple cable cores, and then continue to wrap the inorganic mineral tape on the outer layer;

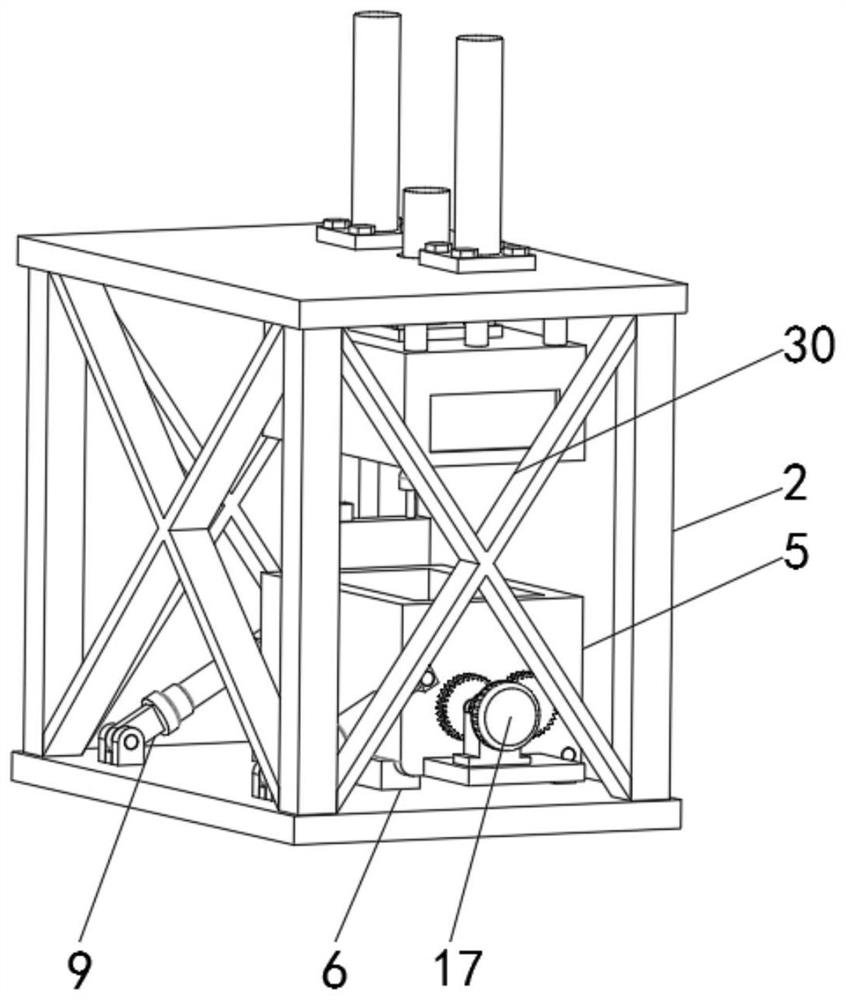

[0108] S3. The aluminum alloy pipe extrusion operation is carried out through the aluminum pipe extrusion machine, and the aluminum alloy pipe sleeve is coated on the inorganic mineral tape to form the semi-finished product of the cable;

[0109] S4. Wrap the oxygen barrier layer on the outside of the semi-finished cable, and finally extrude the flame-retardant outer sheath on the outside to make a multi-core inorganic mineral insulated flexible fireproof cable.

[0110] Wherein, the preparation steps of the inorganic mineral insulating layer used in step S2 are as ...

Embodiment 2

[0129] S1. Remove impurities on the metal surface, straighten after drying, wire drawing and annealing to make a conductive wire core,

[0130] A plurality of conductive wire cores are twisted to form a cable core;

[0131] S2. Wrap an inorganic mineral insulating layer around the cable core, set a filling layer between multiple cable cores, and then continue to wrap the inorganic mineral tape on the outer layer;

[0132] S3. The aluminum alloy pipe extrusion operation is carried out through the aluminum pipe extrusion machine, and the aluminum alloy pipe sleeve is coated on the inorganic mineral tape to form the semi-finished product of the cable;

[0133] S4. Wrap the oxygen barrier layer on the outside of the semi-finished cable, and finally extrude the flame-retardant outer sheath on the outside to make a multi-core inorganic mineral insulated flexible fireproof cable.

[0134] Wherein, the preparation steps of the inorganic mineral insulating layer used in step S2 are as...

Embodiment 3

[0153] S1. Remove impurities on the metal surface, straighten after drying, wire drawing and annealing to make a conductive wire core,

[0154] A plurality of conductive wire cores are twisted to form a cable core;

[0155] S2. Wrap an inorganic mineral insulating layer around the cable core, set a filling layer between multiple cable cores, and then continue to wrap the inorganic mineral tape on the outer layer;

[0156] S3. The aluminum alloy pipe extrusion operation is carried out through the aluminum pipe extrusion machine, and the aluminum alloy pipe sleeve is coated on the inorganic mineral tape to form the semi-finished product of the cable;

[0157] S4. Wrap the oxygen barrier layer on the outside of the semi-finished cable, and finally extrude the flame-retardant outer sheath on the outside to make a multi-core inorganic mineral insulated flexible fireproof cable.

[0158] Wherein, the preparation steps of the inorganic mineral insulating layer used in step S2 are as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com