Rapid fusing device, rapid fusing control method, DC circuit breaker and control method thereof

A DC circuit breaker and control method technology, applied in the direction of emergency protection circuit devices, electrical components, etc., can solve the problems of slow opening action, reduce the fault removal speed of DC circuit breakers, etc., and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

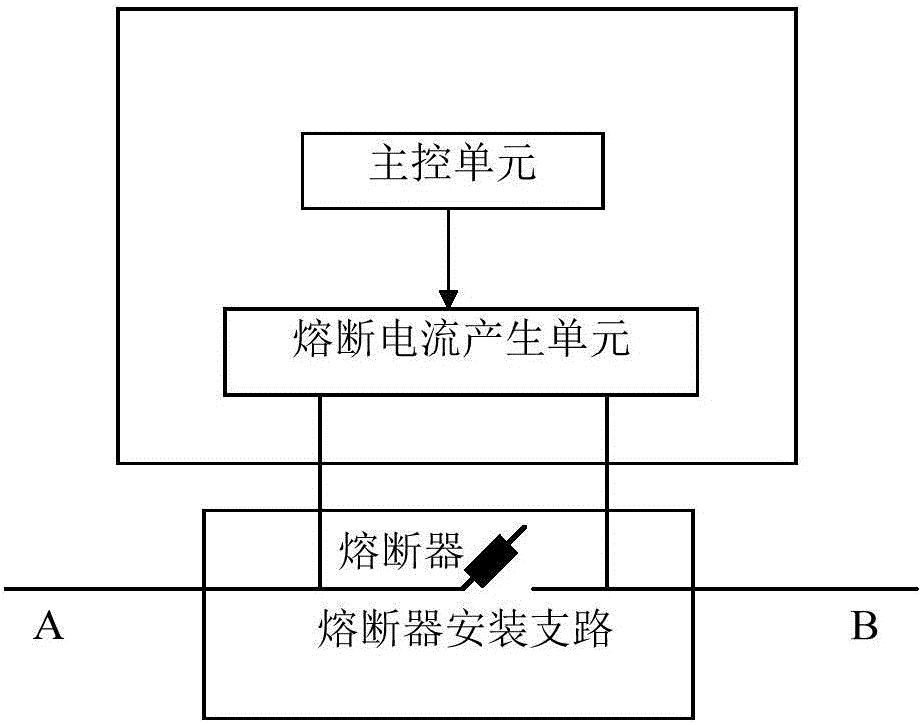

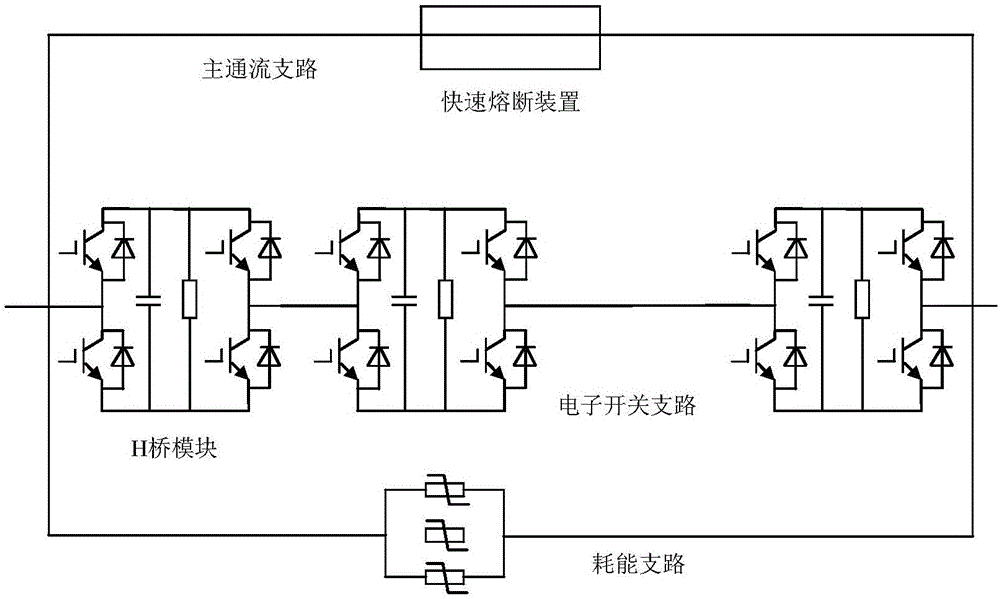

[0044] figure 2 A topological diagram of a DC circuit breaker is given, which includes a main flow branch, an electronic switch branch and an energy consumption branch connected in parallel. Wherein, the main current flow branch includes a fast-fusing device, which includes a fuse installation branch for installing a fuse, and the fuse installation branch is used to be arranged in series in the line; the fast-fuse device also includes a The fusing current generating unit, the two ends of the fusing current generating unit are connected in parallel to the two ends of the fuse installation branch, and are used to output the fusing current to the fuse installation branch; the fast fusing device also includes a main control unit, the main control The unit controls the fusing current generating unit to generate the fusing current. The electronic switching branch includes several series-connected H-bridge modules for assisting the commutation of the main co-current branch. The en...

Embodiment 2

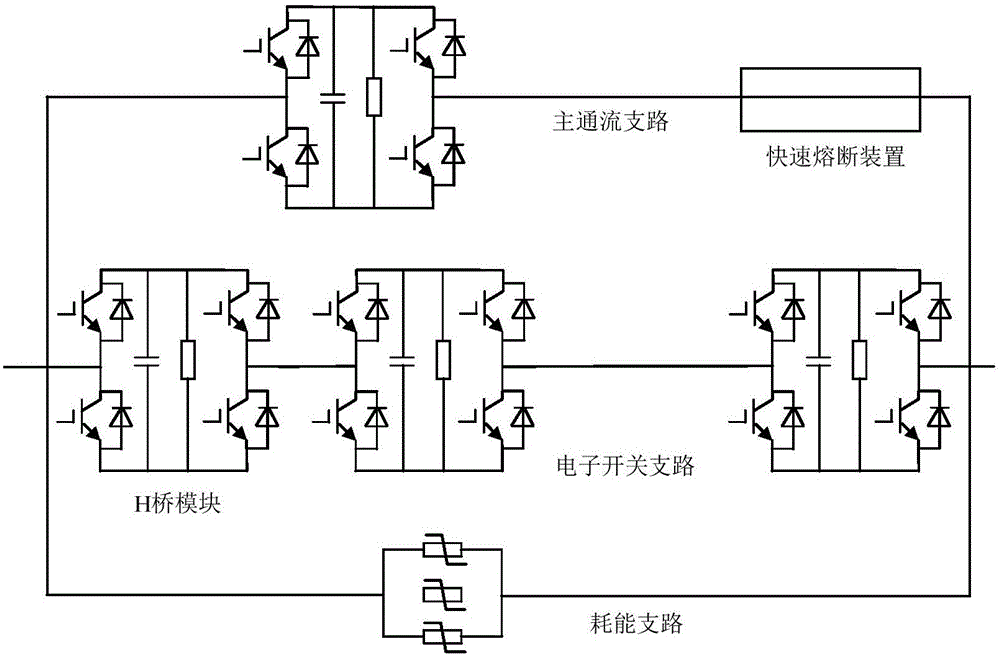

[0047] Such as image 3 As shown, the example is in figure 2 On the basis of , an auxiliary switch module is connected in series with the main flow branch, and the auxiliary switch module is specifically an H-bridge module, which is used to commutate current with the auxiliary electronic switch branch. Similarly, the auxiliary switch module can also be a half-bridge module or a deformed module of the H-bridge module in the prior art, and the number can be more than one.

Embodiment 3

[0049] Such as Figure 4 As shown, the example is in image 3 On the basis of the main flow branch, a mechanical switch is connected in series. After the fuse of the main flow branch is quickly blown, the physical disconnection of the line is realized by turning off the mechanical switch, and the fault is reliably isolated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com