Rigid-flex board with high bending resistance

A rigid-flex board and rigid-flex technology, applied in the field of rigid-flex boards, can solve problems such as scrapping, excessive glue dispensing, and low production efficiency, to eliminate rigid-flex boards, increase the number of bending times, and improve production efficiency effect

Active Publication Date: 2019-02-15

江西弘信柔性电子科技有限公司

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the existing four-layer rigid-flex combined plate combined with 1-2-1 structure cannot meet the needs of more than 100,000 bending times

In order to meet the requirements of the number of bending times, the method of dispensing glue at the rigid-flexible joint is now used to eliminate the stress during bending, but the workload of dispensing is large and the production efficiency is low. At the same time, dispensing is also prone to excessive dispensing or insufficient dispensing, resulting in scrap

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0024] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

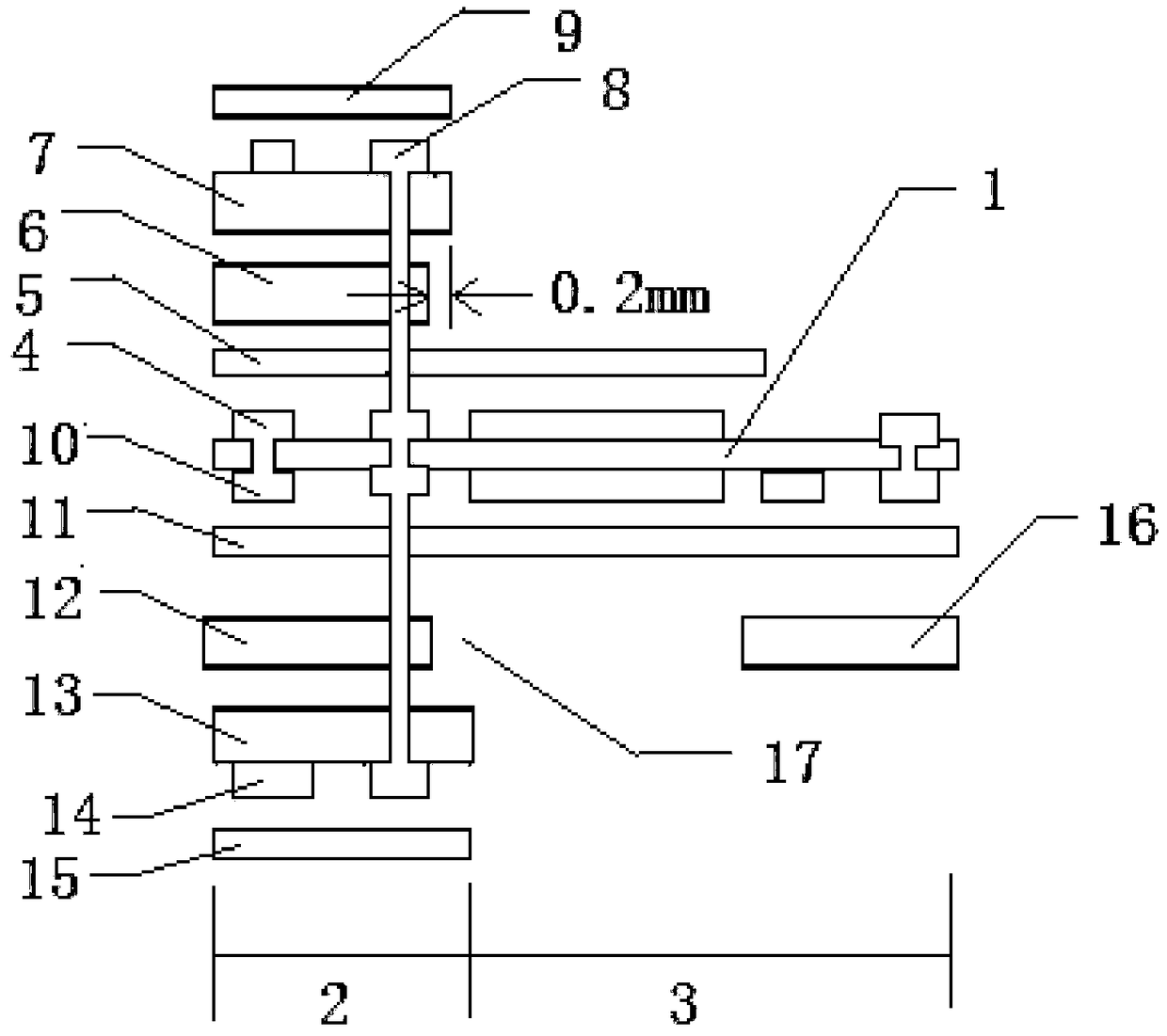

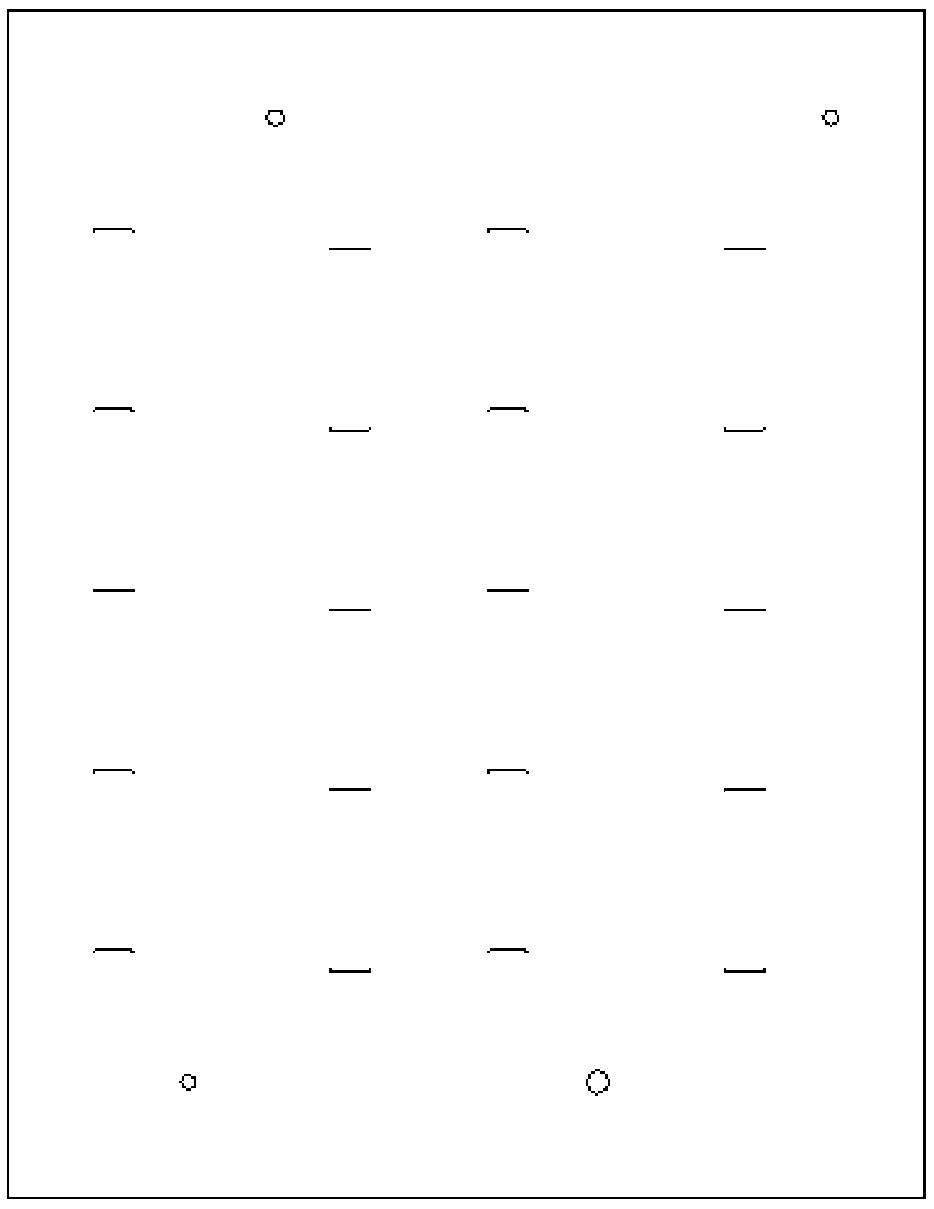

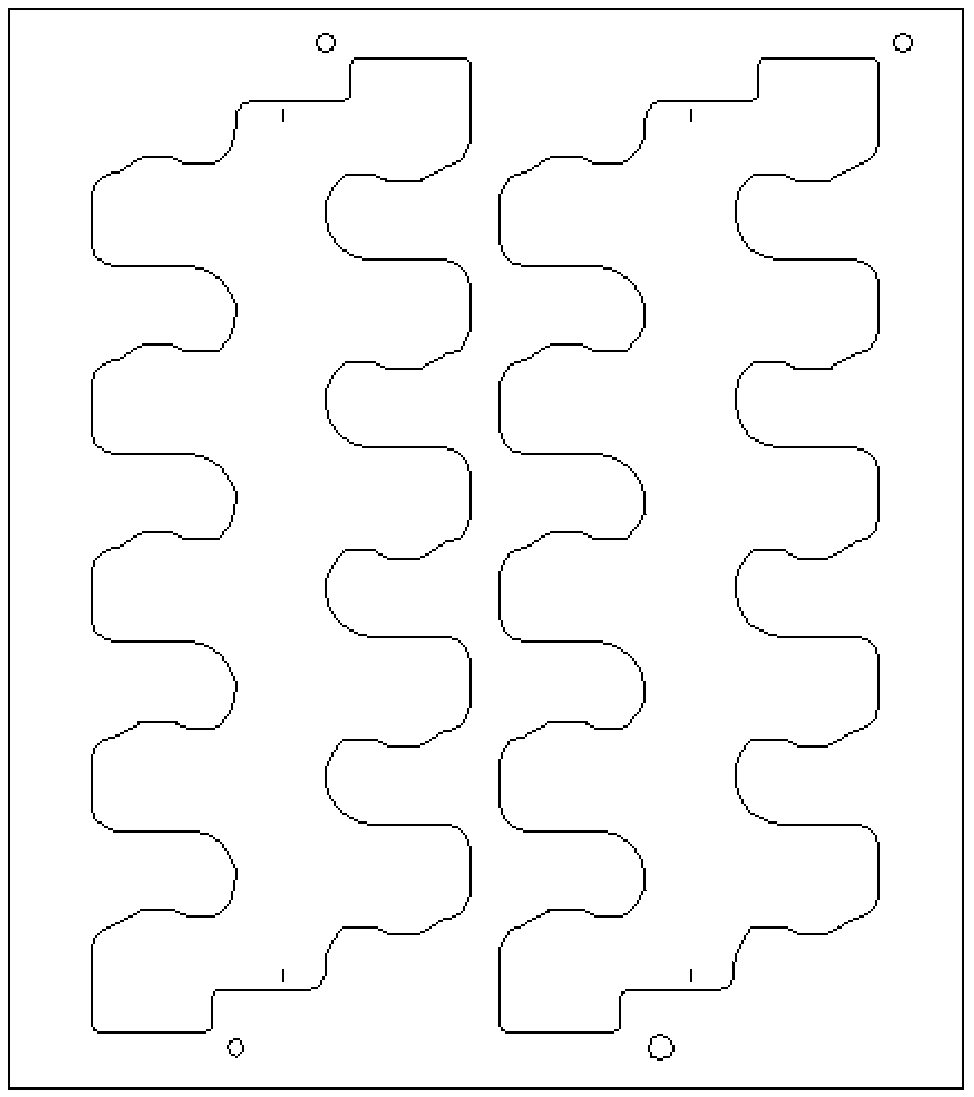

The invention relates to a high rupture resistant rigid-flex printed circuit board (PCB). The high rupture resistant rigid-flex printed circuit board is characterized in that an interlayer of the rigid-flex printed circuit board is a polyimide layer, a PCB rigid board portion is arranged on the inner side of the polyimide layer, and a FPC (flexible printed circuit) flexible board portion is arranged on the outer side of the polyimide layer; an L2 circuit board, an upper cover membrane, an upper layer prepreg, an upper FR4 layer, an L1 circuit board and an upper resistance welding layer are sequentially overlapped on the upper surface of the interlayer from bottom to top; an L3 circuit board, a lower cover membrane, an lower layer prepreg, a lower FR4 layer, an L4 circuit board and a lower resistance welding layer are sequentially overlapped on the lower surface of the interlayer; the upper FR4 extends outwards 0.2mm relative to the upper layer prepreg, the lower FR4 layer extends outwards 0.2mm relative to the lower layer prepreg, a concave is formed in the rigid-flex junction, rigid-flex combination is removed, and the number of bending times is increased.

Description

technical field [0001] The invention relates to a rigid-flex board, in particular to a rigid-flex board with high bending resistance. Background technique [0002] With the vigorous development of mobile phone fingerprint identification, the fingerprint module carrier board requires products with small size, high heat resistance, superior bending performance and multi-functional rigid-flex printed circuit boards to be used more and more. However, the existing four-layer rigid-flex composite plate combined with 1-2-1 structure cannot meet the demand for more than 100,000 bending times. In order to meet the requirements of the number of bending times, the method of dispensing glue at the rigid-flex joint is now used to eliminate the stress during bending, but the workload of dispensing is large and the production efficiency is low. At the same time, dispensing is also prone to excessive dispensing or insufficient dispensing, resulting in scrap. Contents of the invention [...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H05K1/14H05K3/36

CPCH05K1/147H05K3/361H05K2201/09036

Inventor 李胜伦

Owner 江西弘信柔性电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com