Rectangular concrete comprehensive pipe gallery prefabricated pipe sections and machining method

A technology of integrated pipe gallery and concrete, applied in the field of construction, can solve the problems of inability to meet the needs, complex construction environment and conditions of the integrated pipe gallery, save time and economic cost, be beneficial to waterproofing and longitudinal stress, and reduce the cost of construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

[0039] As shown in the figure, the technical scheme adopted by the present invention is as follows:

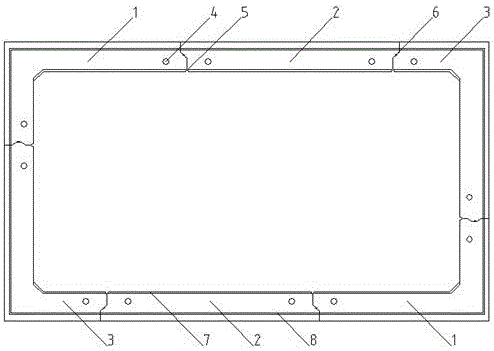

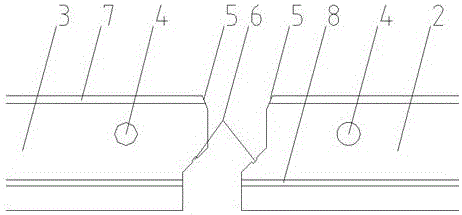

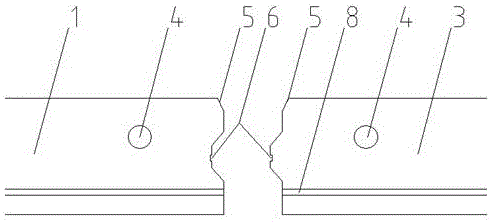

[0040] The prefabricated segment of the rectangular concrete integrated pipe gallery is characterized in that it includes an L-shaped member 1 with a long-end bevel and a short-end chamfer, an in-line prefabricated member 2, and a long-end chamfer and a short-end bevel L-shaped member 3;

[0041] The two ends of the long-end bevel short-end chamfer L-shaped member 1 and the long-end bevel short-end L-shaped member 3 are prefabricated with a chamfer interface and a groove interface respectively, and both ends of the inline prefabricated member 2 are prefabricated Groove interface;

[0042] With a piece of one-shaped prefabricated component 2 as the base, one end of the prefabricated groove of the long-end bevel short-end chamfer L-shaped component 1 and the long-e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com