Transformer vibration on-line monitoring system

A technology for monitoring systems and transformers, applied in the field of electric power systems, can solve problems such as inability to make judgments on iron core conditions, inaccurate results, and different standards, so as to improve reliability and scientific management level, improve economic benefits, and avoid sudden accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

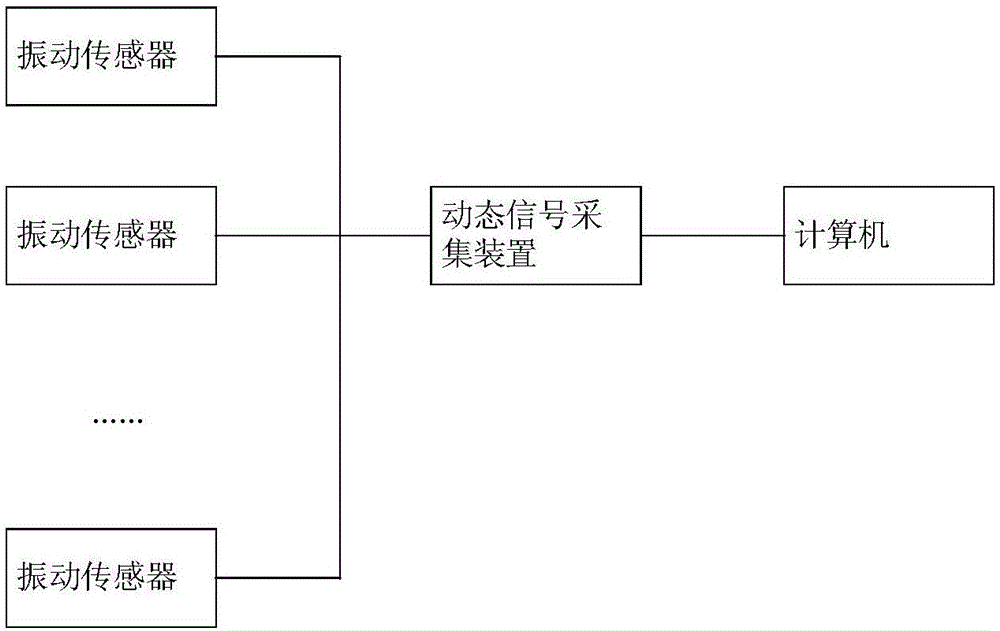

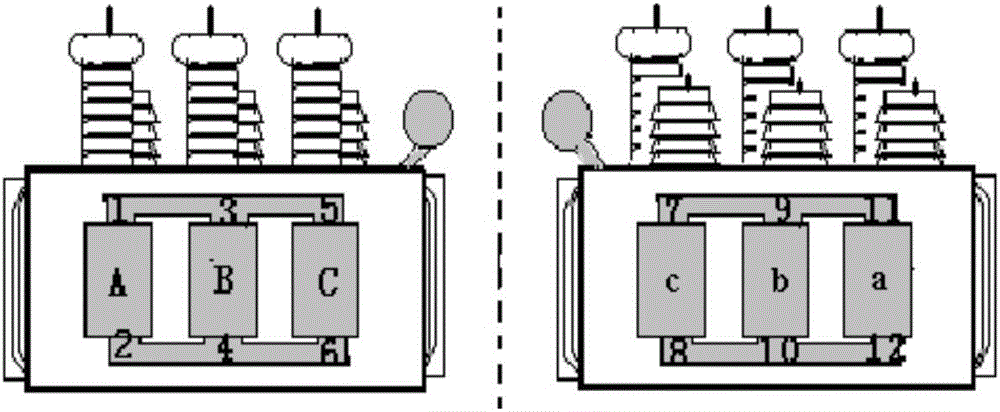

Embodiment Construction

[0026] Considering that removing the load during the operation of the transformer and doing no-load operation will have an impact on the stability of the system and the economic operation of the transformer, the present invention will also study the relationship between the load current and the vibration signal of the device body under online conditions, and study A method to obtain the vibration signal of the transformer core. By this method, the vibration signal of the iron core can be obtained without running the transformer with no load, thereby greatly improving the method of obtaining the vibration signal of the iron core by measuring the vibration signal of the transformer body. At present, there is no reliable means for online or offline monitoring and diagnosis of transformer winding status (looseness, deformation, etc.) at home and abroad. The invention monitors the variation of the vibration acceleration signal of the transformer body at no-load through the vibratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com