110kV transformer low-voltage side outgoing cable contact cabinet

A technology of transformer low-voltage side and contact cabinet, which is applied in the direction of transformer/inductor coil/winding/connection, cable joint, cable installation, etc. It can solve the problems of high heating temperature at the connection end, hidden accidents, and large path resistance. To achieve the effect of increasing the contact area, avoiding oil leakage and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to clearly illustrate the technical features of the solution, the present invention will be described in detail below through specific embodiments and in conjunction with the accompanying drawings.

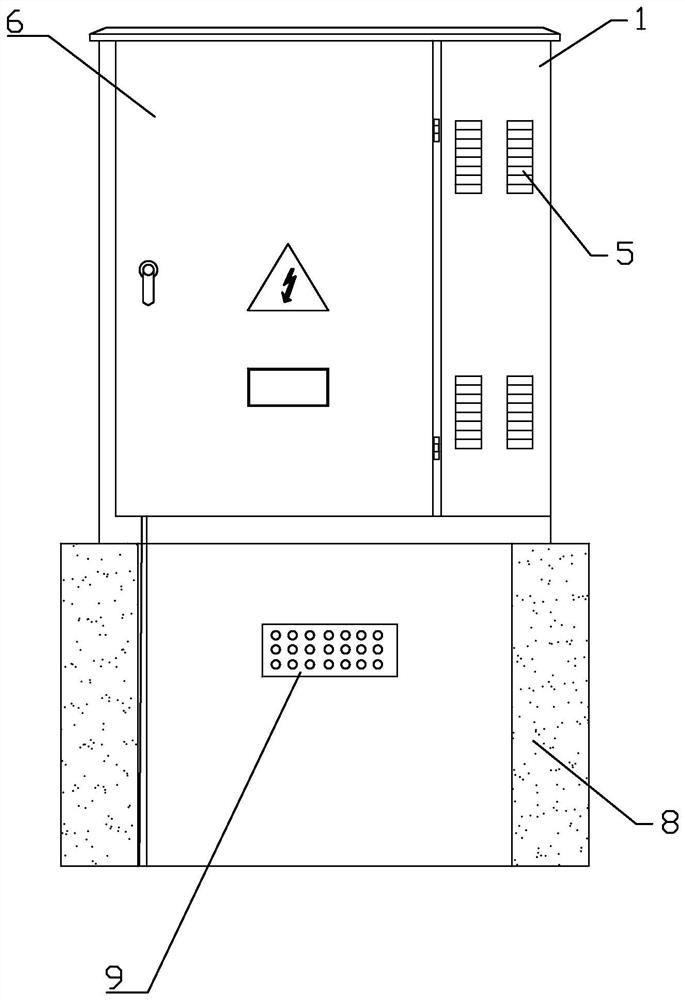

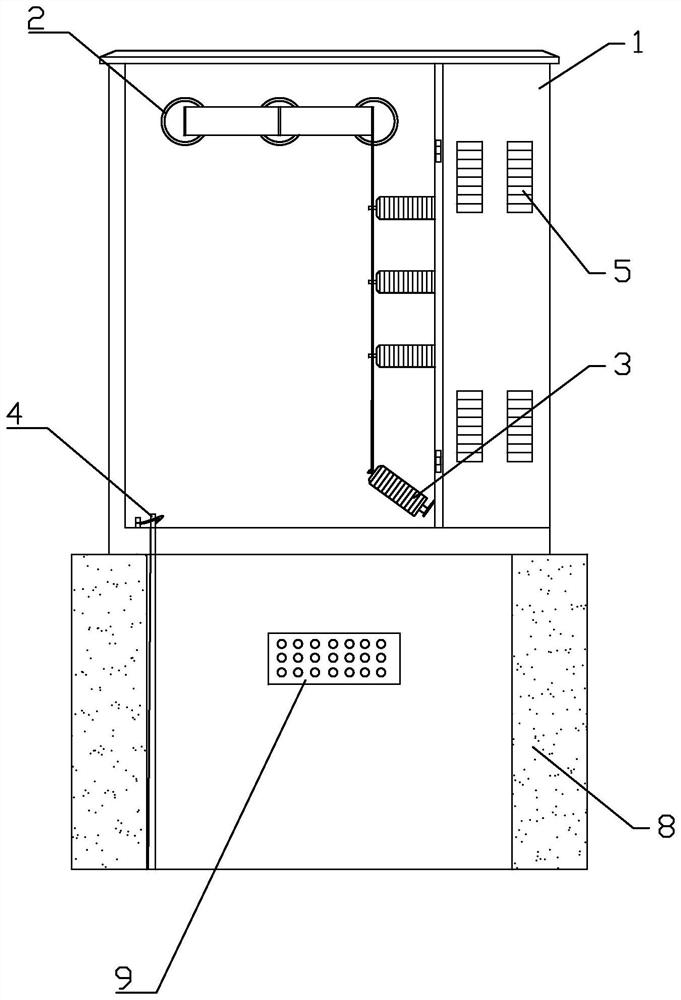

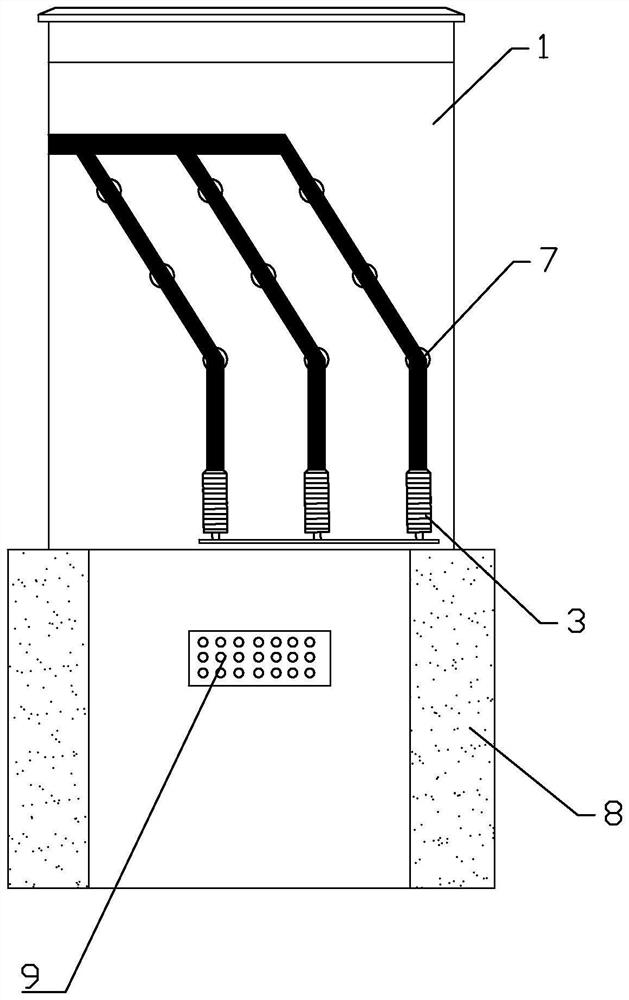

[0025] like Figure 1-8 As shown in the figure, a 110kV transformer low-voltage side outgoing cable connection cabinet, including cabinet 1, is provided with three round holes at equal intervals on the north side of the cabinet, and each round hole is installed with a high-voltage wall bushing 2 through stainless steel bolts , the external terminal of the high-voltage wall bushing 2 is connected with the transformer low-voltage tank oil-filled bushing through the three-phase copper busbar, and the three high-voltage wall bushings are sequentially installed with yellow, green and red high-voltage heat pipes. Shrinkable sleeve; an openable cabinet door 6 is installed on the south side of the cabinet 1 to separate the cabinet 1 into a left cabinet and a right cabinet,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com