Main relay adhesion detection circuit and detection method of vehicle battery management system

A technology for main relays and on-board batteries, which is applied in circuit breaker testing, instruments, and electrical measurement. It can solve problems such as safety, violation, and hidden dangers, and achieve the effects of avoiding continuous discharge, avoiding unsafe factors, and simplifying the design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

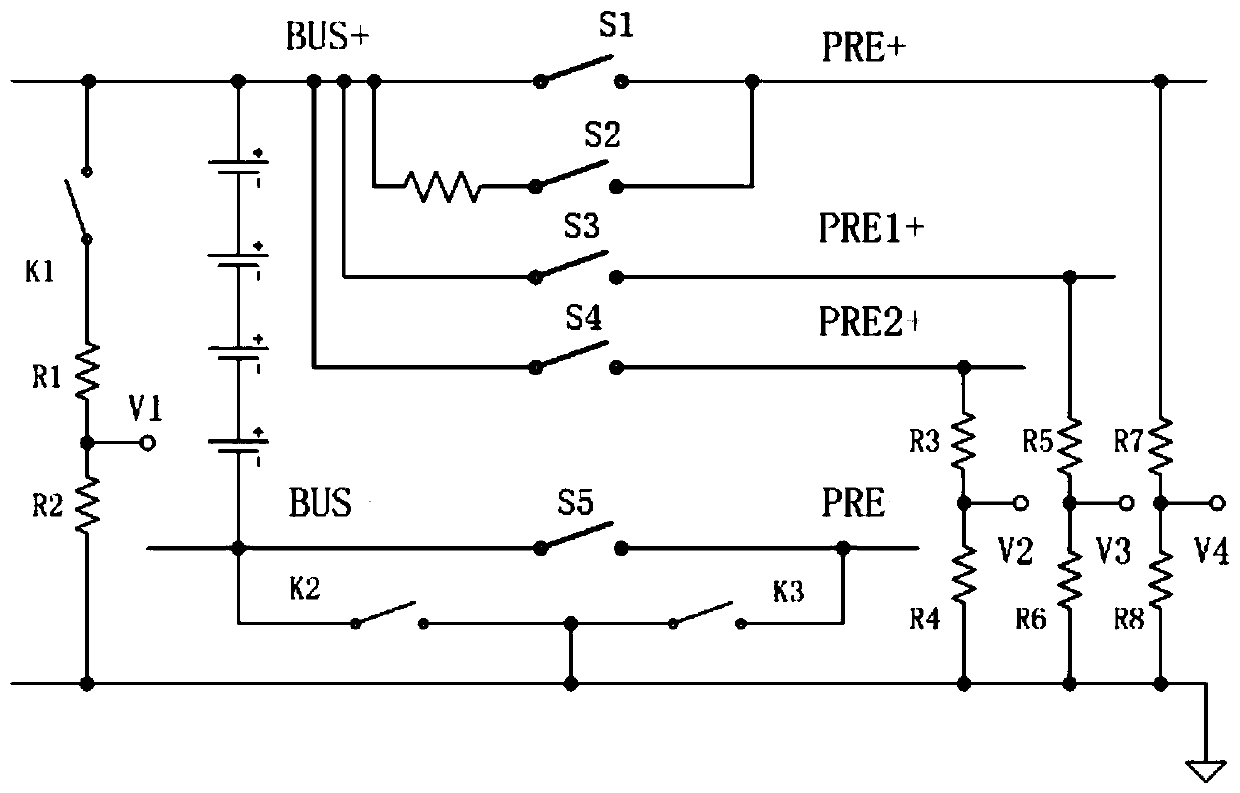

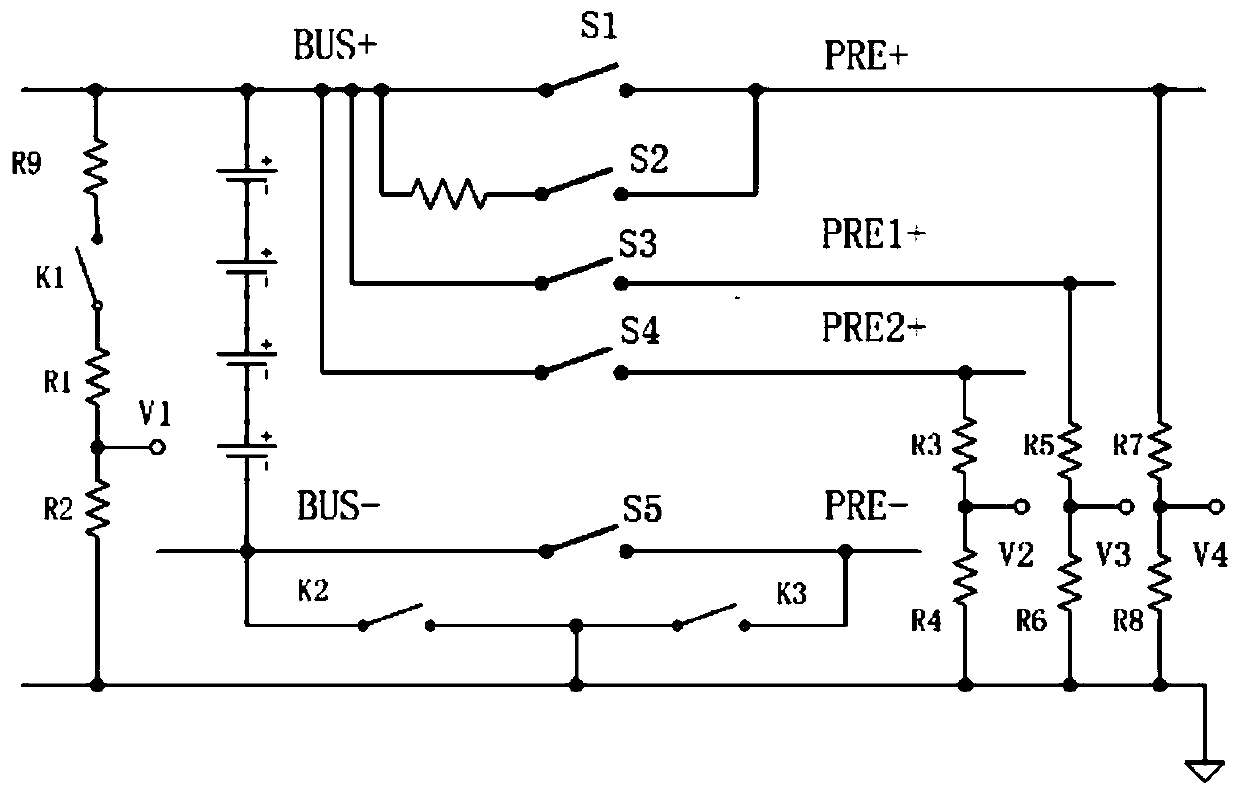

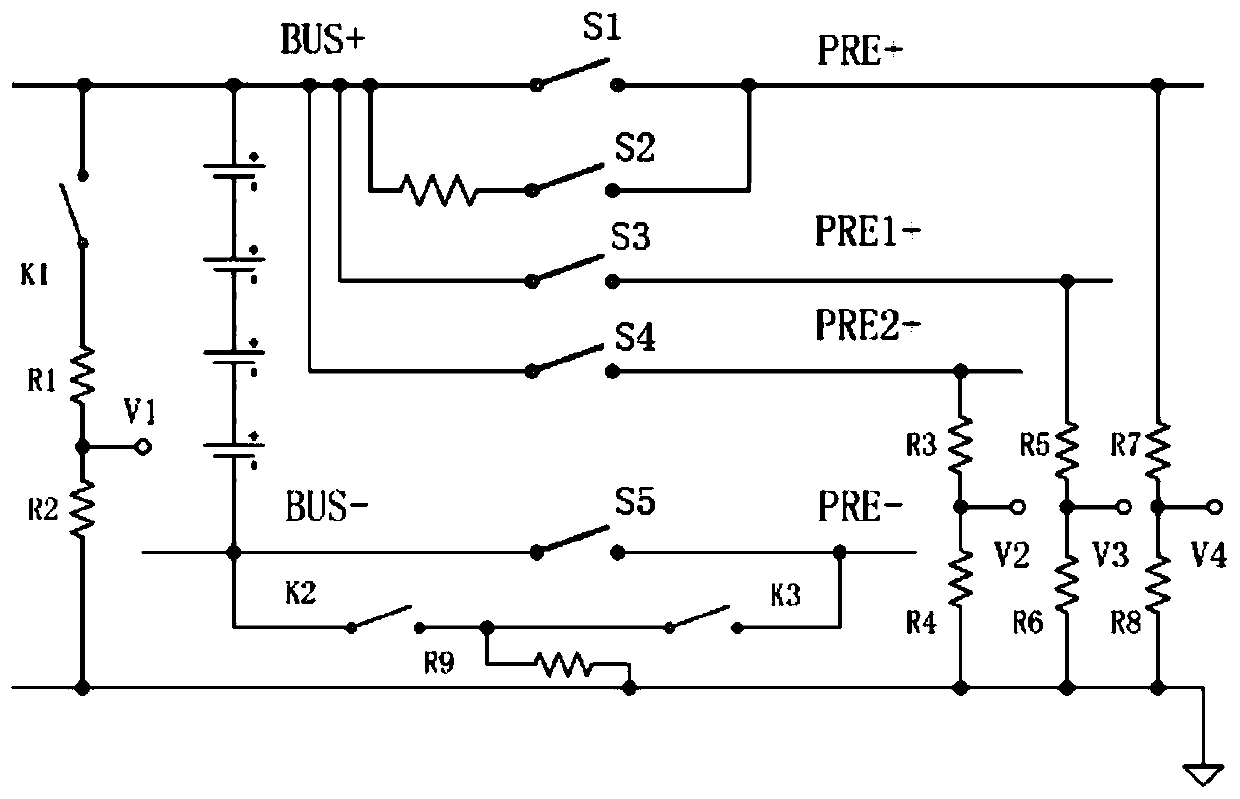

[0048] refer to Figure 1 to Figure 6 , in one embodiment, a main relay adhesion detection circuit of a vehicle battery management system, including a positive bus BUS+, a negative bus BUS-, and a power battery connected between the positive bus BUS+ and the negative bus BUS-, on the positive bus BUS+ There is an overall positive main relay S1, and an overall negative main relay S5 is set on the negative bus BUS-, which also includes a first switch K1, a second switch K2, a third switch K3, a first resistor R1, a second resistor R2, a seventh Resistor R7 and eighth resistor R8, one end of the first switch K1 is connected to the positive bus BUS+, the first resistor R1 and the second resistor R2 are connected in series to form a voltage divider network,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com