A method for assembly and adjustment of spiral bevel gears

A bevel gear and adjustment method technology, which is applied in the field of mechanical processing, can solve the problems of increasing the difficulty of adjustment, blind adjustment process, and reducing the assembly efficiency of spiral bevel gears, etc., and achieve the effect of significant adjustment effect, clear boundary and smooth shape

Inactive Publication Date: 2014-12-03

SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the actual adjustment process, the influence of the unevenness of the backlash of the spiral bevel gear in the tooth length direction on the contact area is ignored, which leads to the blind adjustment process, increases the difficulty of adjustment, and reduces the assembly efficiency of the spiral bevel gear.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

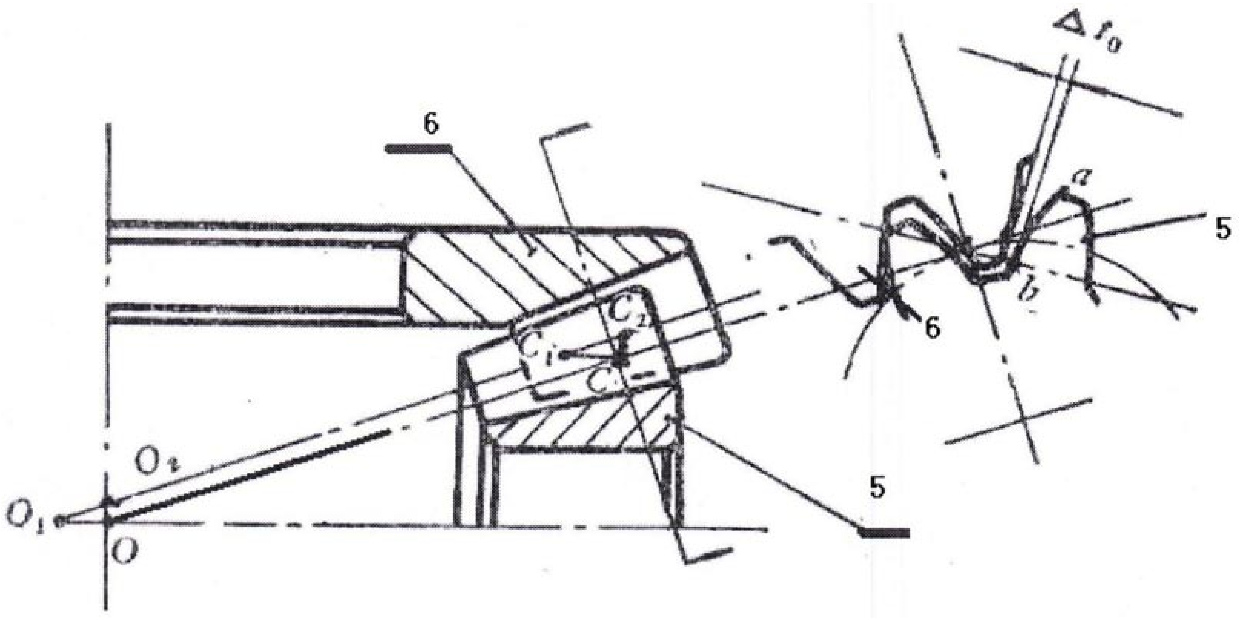

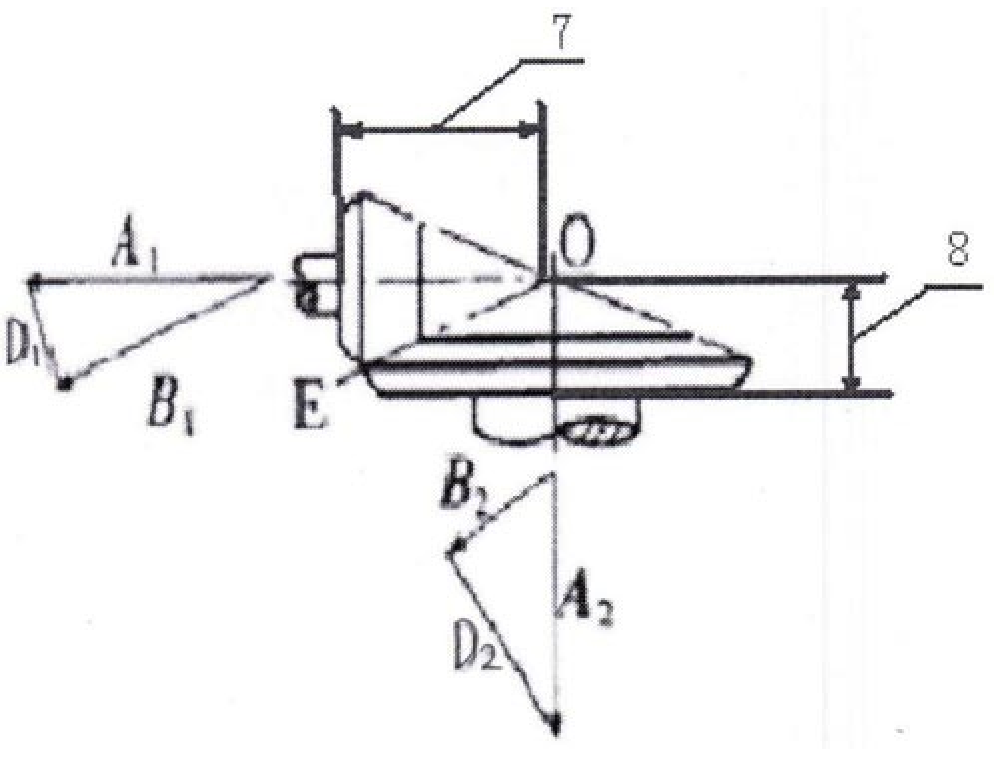

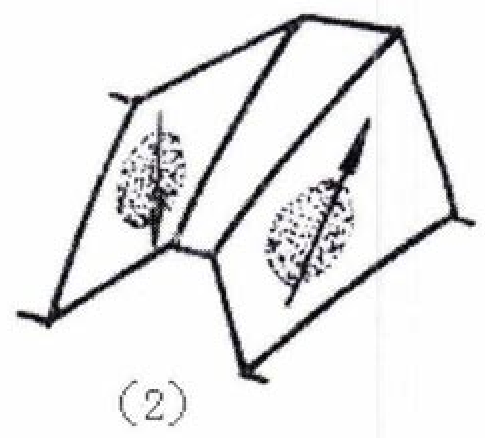

The invention belongs to the technical field of mechanical processing, and relates to a method for assembling and adjusting spiral bevel gears. The adjustment quality of the spiral bevel gear assembly mainly takes the adjustment quality of the contact area as an important index. The position and shape of the contact area of the tooth surface have an important impact on the working stability, life and noise of the spiral bevel gear. According to the structural characteristics and working principle of the spiral bevel gear itself, the present invention analyzes the trend of the gear backlash along the tooth length with the change of the installation distance, which leads to the trend of influence on the position of the gear contact area, and the change of the gear backlash. The position of the contact area of the tooth surface of the gear changes accordingly, and with reference to the actual operation results, the assembly adjustment method is summarized.

Description

A method for assembly and adjustment of spiral bevel gears technical field The invention belongs to the technical field of mechanical processing, and relates to a method for assembling and adjusting spiral bevel gears. Background technique Spiral bevel gears are widely used in the transmission system of aero-engines due to their stable transmission, low noise, and strong load-carrying capacity. In the transmission process, the contact area of the tooth surface of the spiral bevel gear is one of the important signs to measure the meshing quality of the gear. In the assembly process, the adjustment of the contact area is also a particularly important technology. Usually, the adjustment of the contact area is achieved by changing the gear installation distance. However, in the actual adjustment process, the influence of the unevenness of the backlash of the spiral bevel gear in the tooth length direction on the contact area is ignored, which leads to the blind adjustment ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M13/02

Inventor 史华勋李倩华高永进张松野

Owner SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com