Toast bread mold and machining technology thereof

A processing technology and mold technology, which is applied in the field of toast bread mold and toast bread mold processing technology, can solve problems such as bread sticking, bread deformation, and affecting toast bread, and achieve good processing accuracy, high production efficiency, and easy operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In order to achieve the above object, the present invention adopts the following technical solutions:

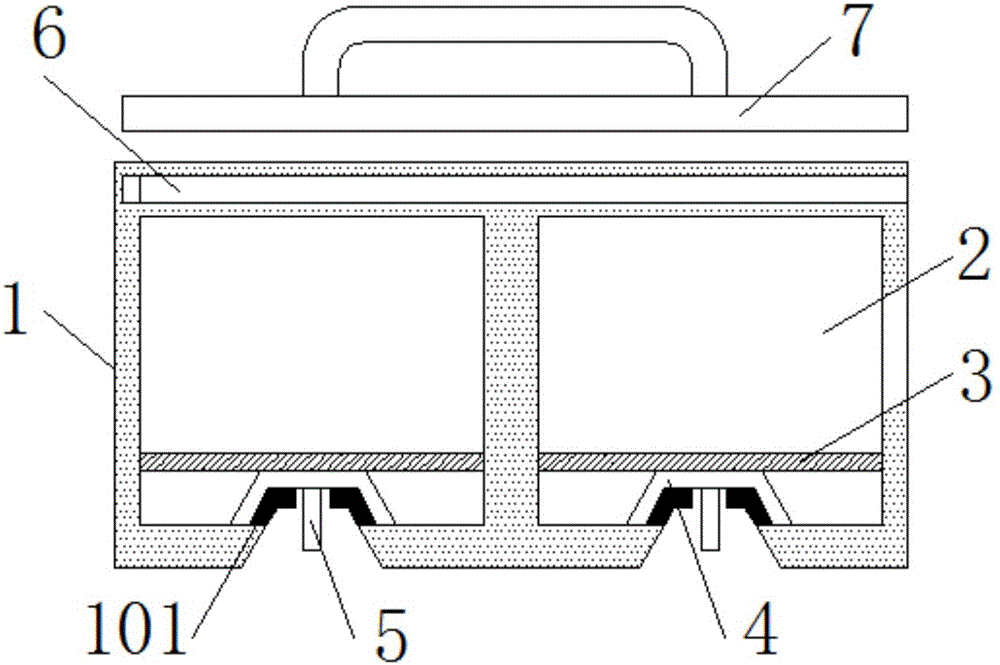

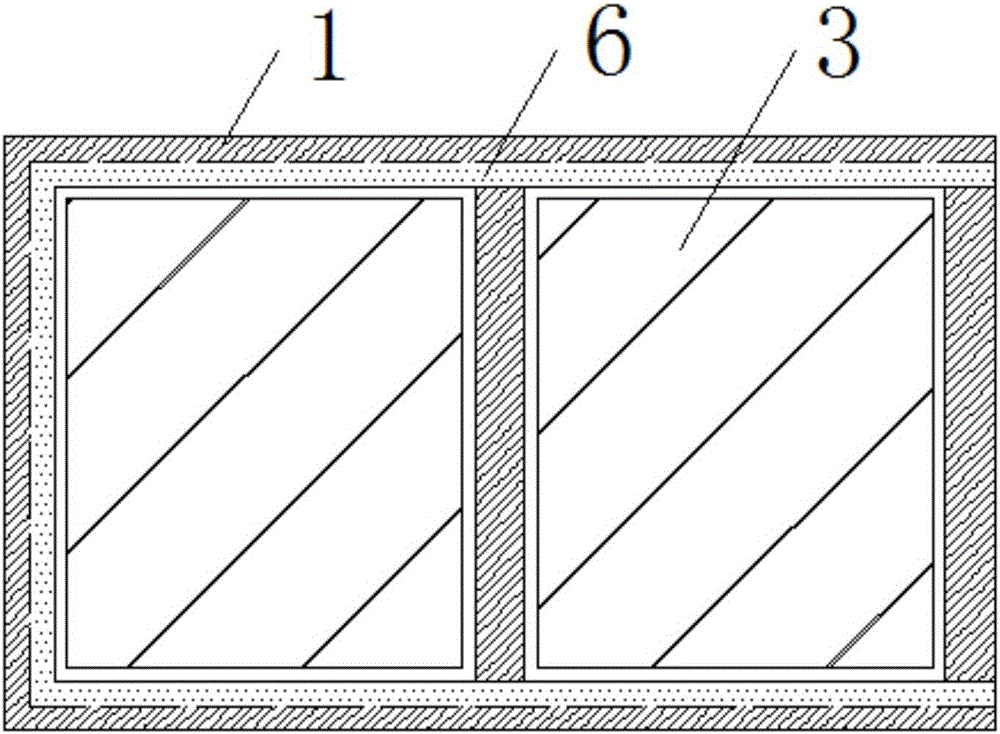

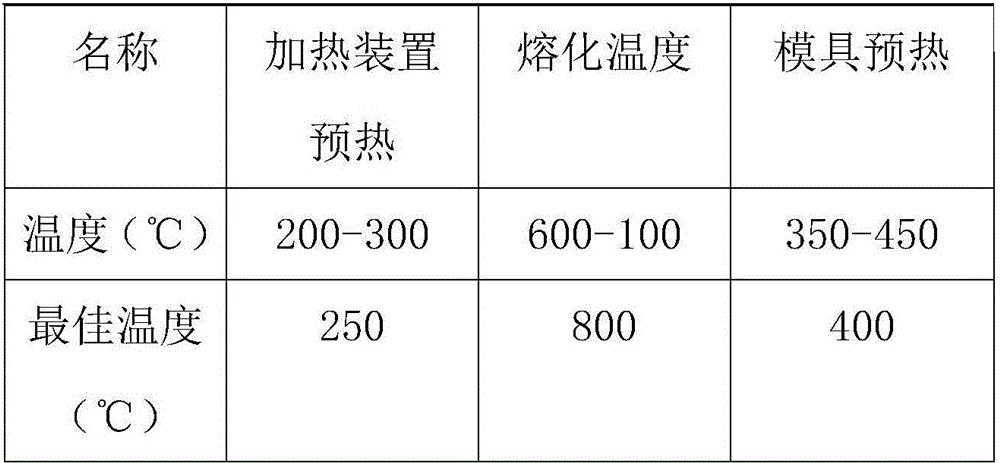

[0031] see Figure 1-2 , a toast bread mold, including a mold body 1, a plurality of groups of mold grooves 2 are arranged in the mold body 1, and an upwardly protruding semi-conical sealing stopper 101 is arranged in the center of the bottom of the mold groove 2 , and the center of the sealing block 101 is provided with a through hole, the mold groove 2 is provided with a stripping plate 3, the cross section of the stripping plate 3 is the same as the cross section shape of the mold groove 2, and the stripping plate 3 and the mold concave The groove 2 is a gap fit, and the bottom center of the stripping plate 3 is provided with a briquetting block 4, and the upper surface of the briquetting block 4 is fixedly connected with the lower surface of the stripping plate 3, the briquetting block 4 is semi-conical, and the sealing block Block 101 above.

[0032] Further, t...

Embodiment 2

[0042] In order to achieve the above object, the present invention adopts the following technical solutions:

[0043] see Figure 1-2 , a toast bread mold, including a mold body 1, a plurality of groups of mold grooves 2 are arranged in the mold body 1, and an upwardly protruding semi-conical sealing stopper 101 is arranged in the center of the bottom of the mold groove 2 , and the center of the sealing block 101 is provided with a through hole, the mold groove 2 is provided with a stripping plate 3, the cross section of the stripping plate 3 is the same as the cross section shape of the mold groove 2, and the stripping plate 3 and the mold concave The groove 2 is a gap fit, and the bottom center of the stripping plate 3 is provided with a briquetting block 4, and the upper surface of the briquetting block 4 is fixedly connected with the lower surface of the stripping plate 3. The briquetting block 4 is semi-conical, and is sleeved on Seal the top of the stopper 101.

[0044...

Embodiment 3

[0054] In order to achieve the above object, the present invention adopts the following technical solutions:

[0055] see Figure 1-2 , a toast bread mold, including a mold body 1, a plurality of groups of mold grooves 2 are arranged in the mold body 1, and an upwardly protruding semi-conical sealing stopper 101 is arranged in the center of the bottom of the mold groove 2 , and the center of the sealing block 101 is provided with a through hole, the mold groove 2 is provided with a stripping plate 3, the cross section of the stripping plate 3 is the same as the cross section shape of the mold groove 2, and the stripping plate 3 and the mold concave The groove 2 is a gap fit, and the bottom center of the stripping plate 3 is provided with a briquetting block 4, and the upper surface of the briquetting block 4 is fixedly connected with the lower surface of the stripping plate 3. The briquetting block 4 is semi-conical, and is sleeved on Seal the top of the stopper 101.

[0056...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com