Shoe mold cutting machine capable of automatically taking materials and preventing materials from moving

A technology of automatic material reclaiming and die cutting machine, applied in the direction of shoemaking machinery, footwear, clothing, etc., can solve the problems of low efficiency of material replacement, manual removal of shoe materials, and easy sliding of materials, saving labor and improving Product quality, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

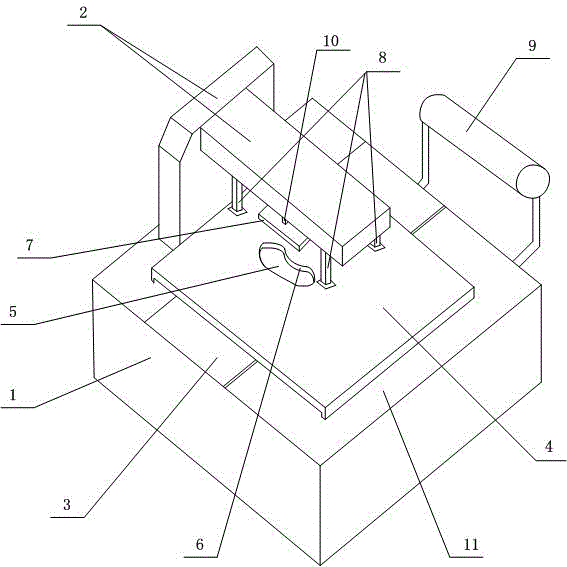

[0024] Such as figure 1 As shown, a shoe mold cutting machine that automatically takes materials and prevents material from moving in the present invention includes a frame 1, a working platform 11, a molding mechanism 2 arranged on the working platform close to one side, and also includes a mold set on the working platform. The shoe template 4 on the platform is provided with a shoe mold hole 5, and the side wall of the shoe mold hole is provided with a knife mold 6 having the same shape as the shoe mold hole; The briquetting block 7 directly above the hole has the same shape as the shoe mold hole; the briquetting block is connected to the die mechanism through a telescopic rod 10, which can be extended or shortened to control the compression The block drops or rises; a transmission belt 3 is provided between the working platform and the shoe template; the press molding mechanism also includes four fixed rods 8, and the four fixed rods are respectively located around the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com