Stainless steel continuous rolling mill and its rolling process

A technology of stainless steel and stainless steel strip, which is applied in the field of rolling technology and stainless steel continuous rolling mills, and can solve the problems of increased investment and production and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The principles and features of the present invention are described below in conjunction with the accompanying drawings. The described embodiments are only used to explain the present invention, and are not intended to constitute any limitation to the scope of the present invention. The scope of protection claimed by the present invention is only through the appended rights Requirements to limit.

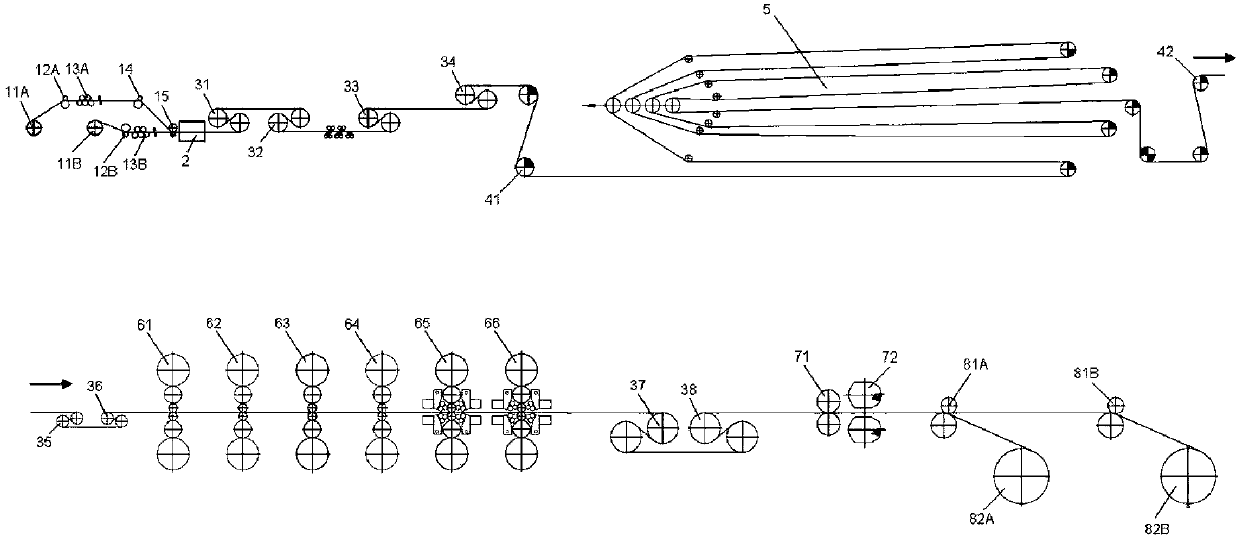

[0019] exist figure 1 Described in the stainless steel continuous rolling unit of the present invention, according to the advancing direction of stainless steel strip, comprise successively: uncoiler 11A, 11B, pinch roll 12A, 12B, five-roll straightener 13A, 13B, turn to pinch roll 14, convergent Pinch roller 15, laser welding machine 2, 1# tension roller 31, 2# tension roller 32, 3# tension roller 33, 4# tension roller 34, 1# correction roller 41, horizontal looper device 5, 2# correction roller 42. 5# tension roller 35, 6# tension roller 36, F1 mill 61, F2 mill 62, F3 mill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com