A kind of nano zinc oxide and preparation method thereof

A nano-zinc oxide and zinc source technology, applied in the field of nano-materials, can solve the problems of large nano-particle size, easy aggregation of nano-particles, and small specific surface area, and achieve good dispersion, uniform supersaturation, and improved mixing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

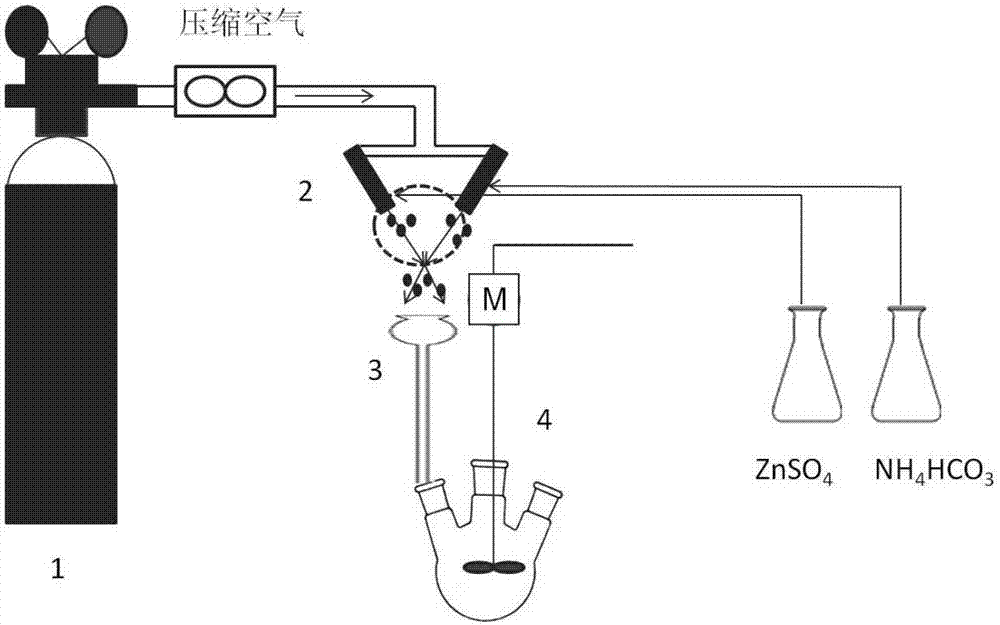

[0029] The invention provides a kind of preparation method of nanometer zinc oxide, comprises the following steps:

[0030] (1) Mix and atomize the zinc source solution and the compressed gas to obtain the gas-carrying zinc source droplets;

[0031] (2) Mixing and atomizing the carbonate precipitating agent solution with compressed gas to obtain gas-carrying precipitating agent droplets;

[0032] (3) spraying and mixing the gas-carrying zinc source droplets obtained in the step (1) with the gas-carrying precipitant droplets obtained in the step (2), and obtaining a precursor by precipitation reaction;

[0033] (4) roasting the precursor that described step (3) obtains, obtains nano zinc oxide;

[0034] The steps (1) and (2) are in no chronological order.

[0035] The invention mixes and atomizes the zinc source solution and the compressed gas to obtain the gas-carrying zinc source droplet. In the present invention, the zinc source is preferably a soluble zinc salt, more pre...

Embodiment 1

[0050] Using zinc sulfate heptahydrate solution with a concentration of 0.8mol / L and ammonium bicarbonate solution with a concentration of 1.6mol / L as the reactant solution, the compressed gas of 0.4MPa quickly passes through the nozzle, forming a pressure difference at both ends of the nozzle, and the reactant Brought into the mixing chamber of the nozzle respectively, in the mixing chamber, the gas quickly cuts the reactant and atomizes the reactant into liquid droplets;

[0051] The atomized reactants are taken out of the nozzle by the airflow, and outside the nozzle, two airflows with a gas-liquid ratio of 800 are sprayed at a rate of 60L / min, and collision and direct precipitation reaction occur to produce precursor particles;

[0052] Precursor particles are brought into the three-necked flask adapter by the airflow, and mechanically stirred and aged at a speed of 70r / min for 1h;

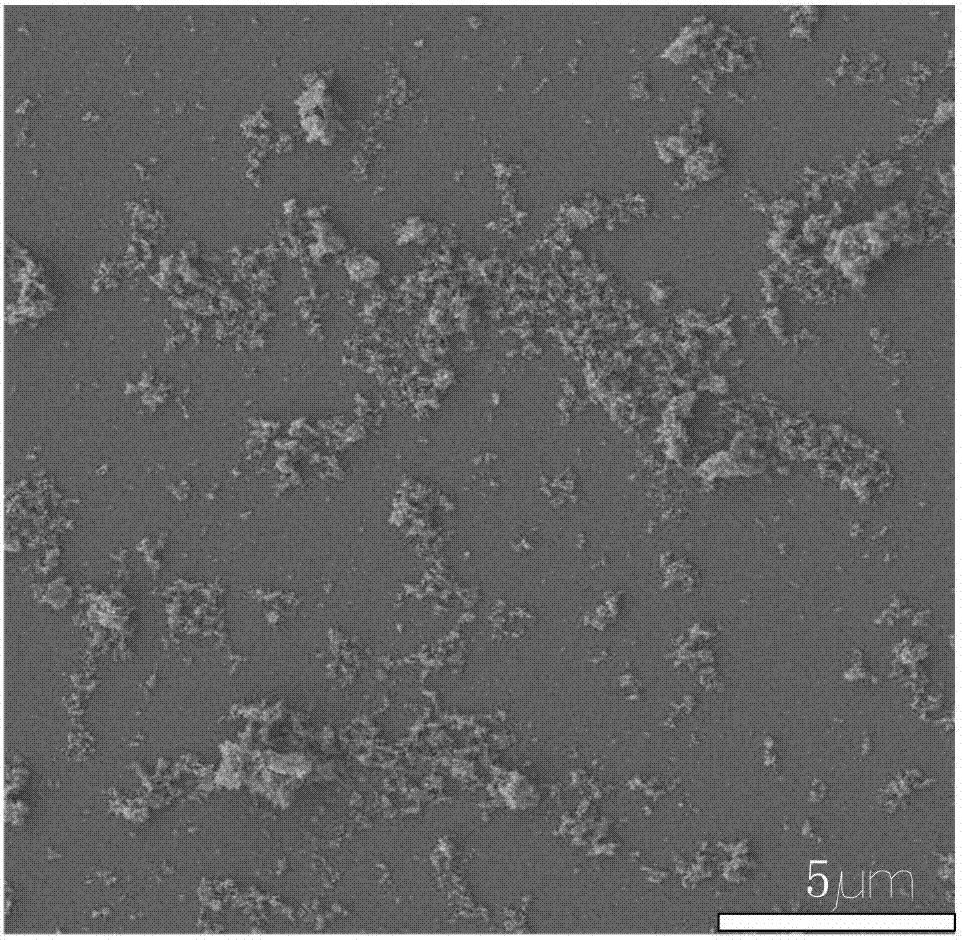

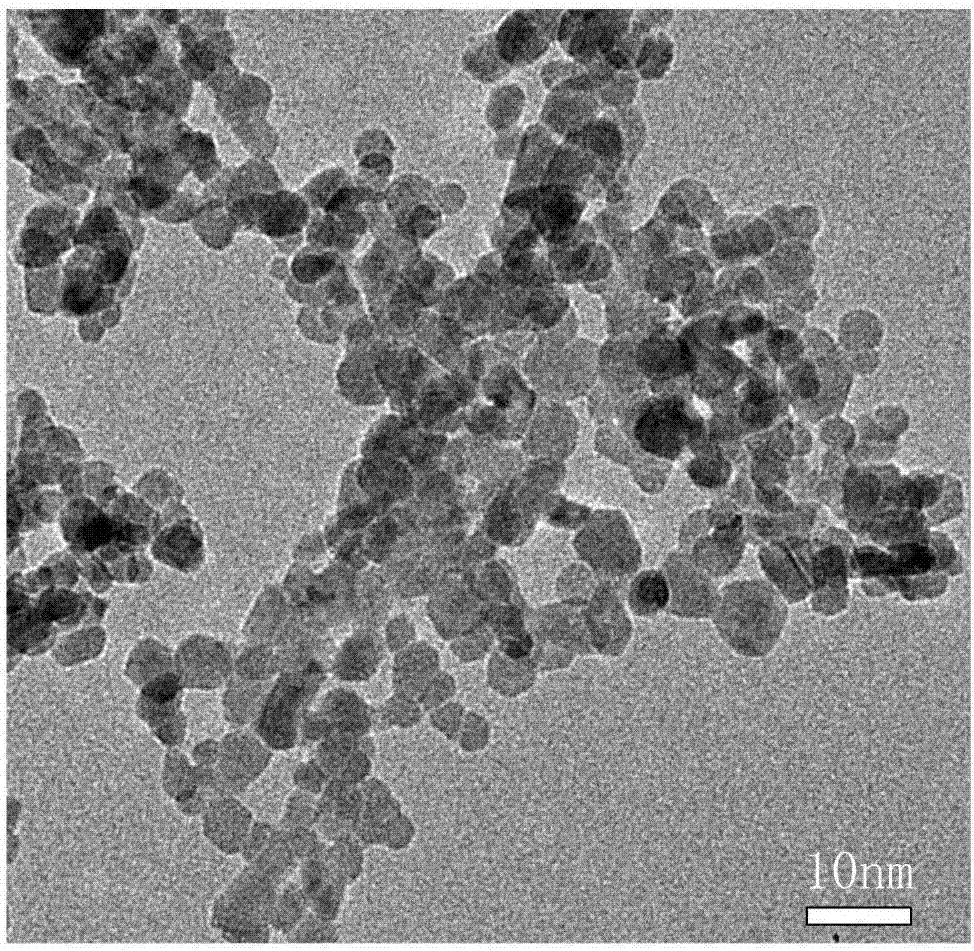

[0053] Suction filtration, the obtained solid was washed three times with deionized water ...

Embodiment 2

[0057] Using zinc sulfate heptahydrate solution with a concentration of 0.6mol / L and ammonium bicarbonate solution with a concentration of 1.2mol / L as the reactant solution, the compressed gas of 0.4MPa quickly passes through the nozzle, forming a pressure difference at both ends of the nozzle, and the reactant Brought into the mixing chamber of the nozzle respectively, in the mixing chamber, the gas quickly cuts the reactant and atomizes the reactant into liquid droplets;

[0058] The atomized reactants are taken out of the nozzle by the airflow, and outside the nozzle, two airflows with a gas-liquid ratio of 1000 are sprayed at a rate of 70L / min, and the precursor particles are produced by collision and direct precipitation reaction;

[0059] Precursor particles are brought into the three-necked flask adapter by the airflow, and mechanically stirred and aged at a speed of 70r / min for 1h;

[0060] Suction filtration, the obtained solid was washed three times with deionized wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com