Genetically engineered bacteria for co-production of isoprene and 1,3-propanediol and its construction method and application

A technology of genetically engineered bacteria and isoprene, applied in the field of genetic engineering, can solve the problems of energy waste and loss in biosynthesis, and achieve the effect of increasing yield and balancing metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] The construction of embodiment 1 genetically engineered bacteria

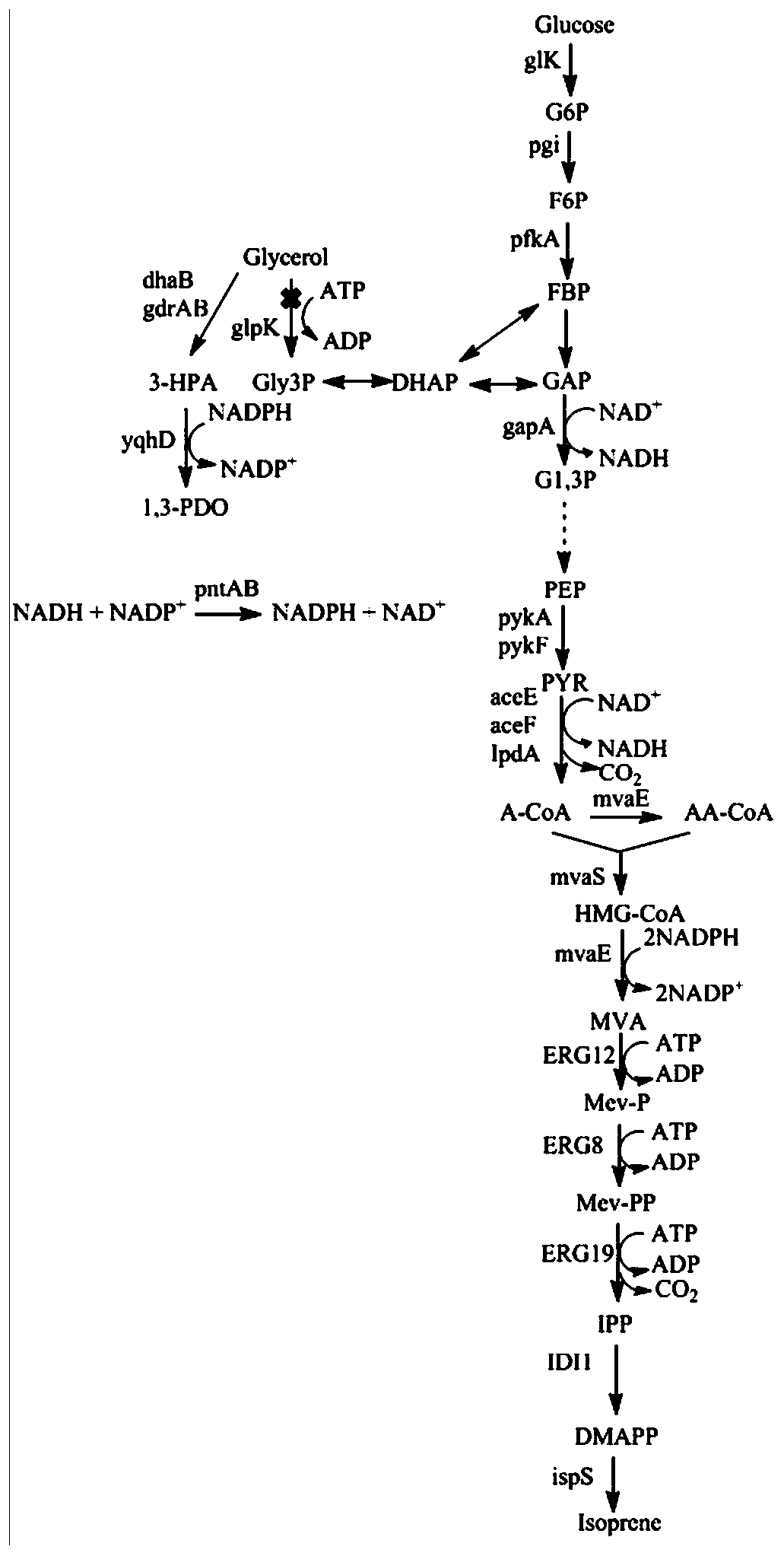

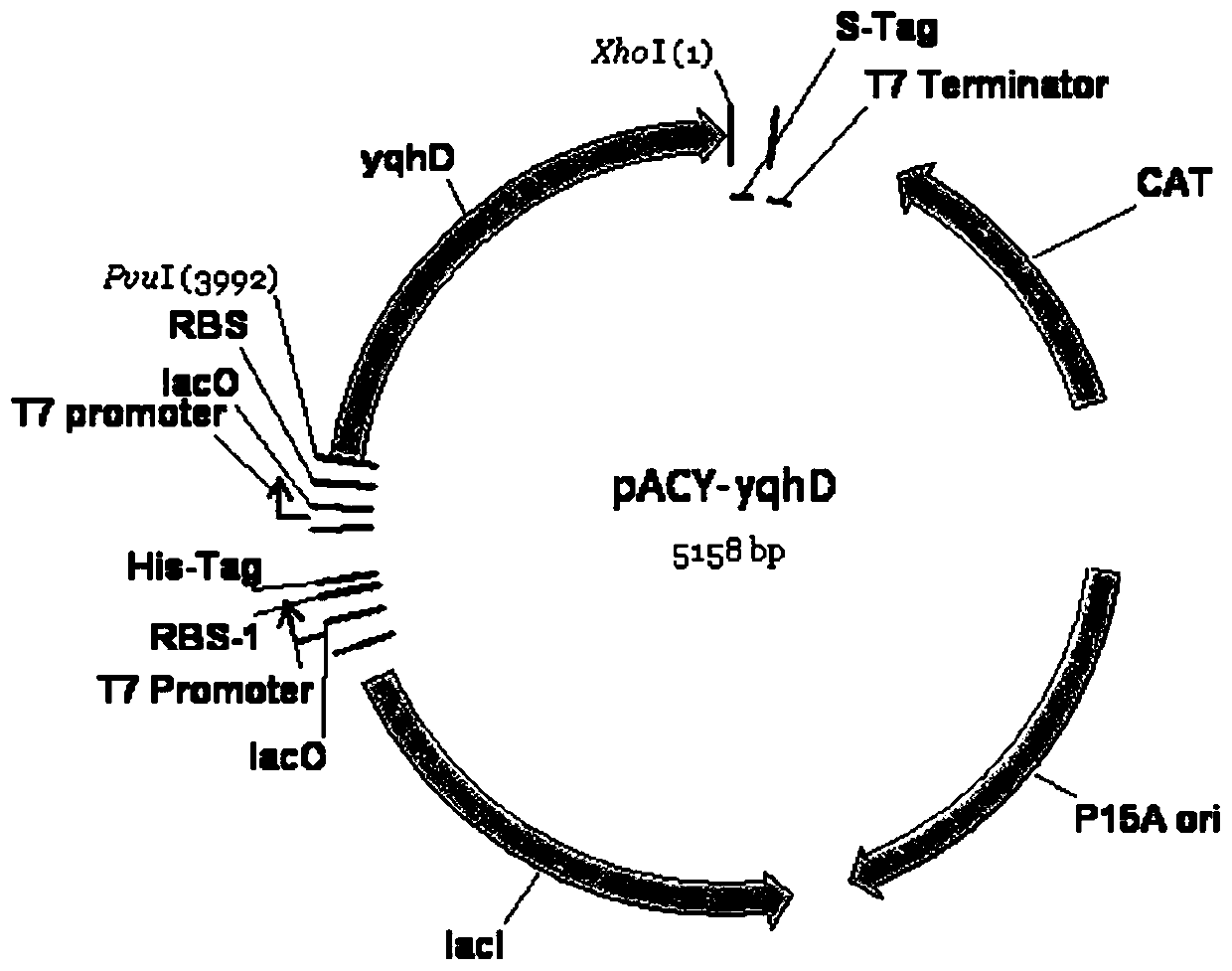

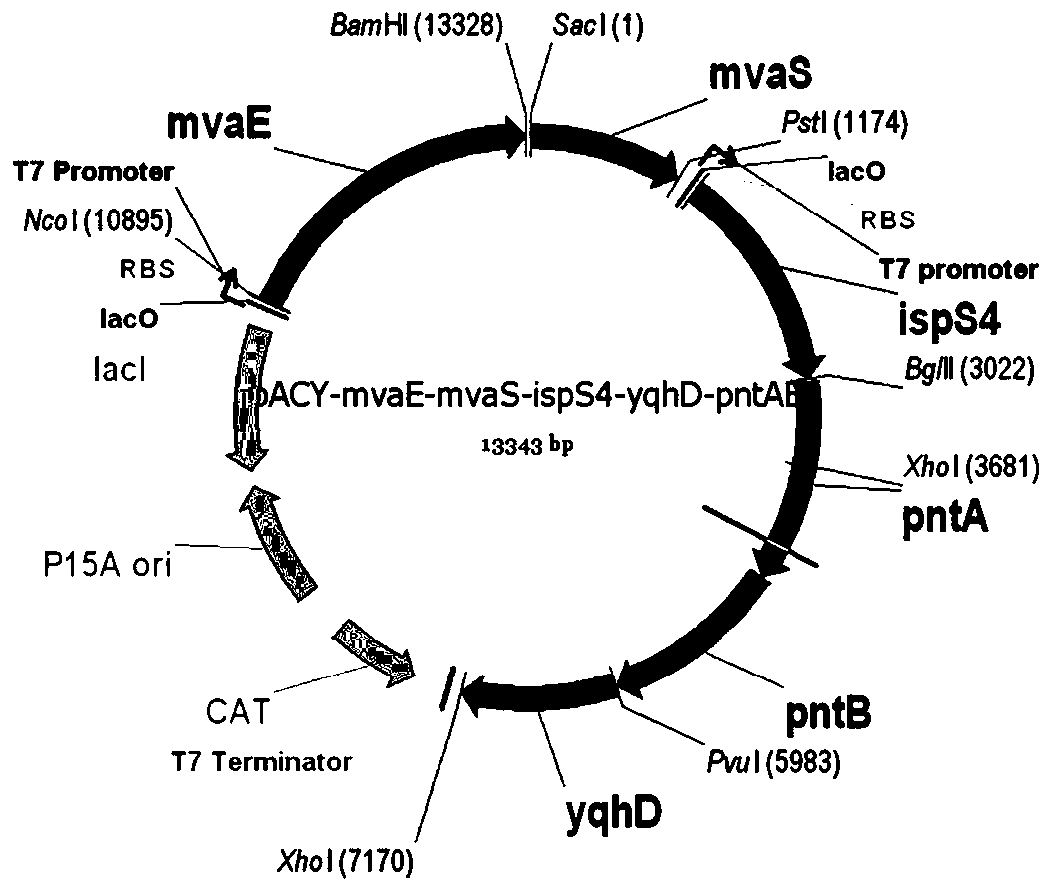

[0088] Overexpression of acetyl-CoA acyltransferase / HMG-CoA reductase gene and HMG-CoA synthetase in Escherichia coli in which the glycerol dehydratase gene and glycerol dehydratase reactivator gene were integrated in the genome and the glycerol kinase gene was knocked out gene, mevalonate kinase gene, phosphomevalonate kinase gene, pyrophosphomevalonate decarboxylase gene, isopentenyl pyrophosphate isomerase gene, isoprene synthase gene, aldehyde reductase gene and Transhydrogenase gene, the obtained genetically engineered bacteria can use glucose and glycerol mixed carbon source fermentation to co-produce isoprene and 1,3-propanediol, and at the same time realize the regeneration of NADPH in the cell. Metabolic pathways and cofactor modification methods of co-production strains such as figure 1 shown.

[0089] 1. Gene integration

[0090] 1.1 Integrate glycerol dehydratase gene dhaB and glycerol deh...

Embodiment 2

[0138] Example 2 Fermentative production of isoprene and 1,3-propanediol

[0139] 1. Seed medium: yeast powder 5g / L, NaCl 10g / L, peptone 10g / L. The culture of G01, G02, G03 and 2369 needs to add 100 μg / mL of ampicillin and 34 μg / mL of chloramphenicol, and only 34 μg / mL of chloramphenicol is added for the culture of G04 strain.

[0140] 2. Fermentation medium: K 2 HPO 4 ·3H 2 O 9.8g / L, Citric acid·H 2 O 2.1g / L, ferric ammonium citrate 0.3g / L, beef extract 5g / L, 1mol / L MgSO 4 ·7H 2 O 2ml / L, 1mL 1000×trace elements ((NH 4 ) 6 Mo 7 o 24 4H 2 O3.7g / L; ZnSO 4 ·7H 2 O 2.9g / L; H 3 BO 3 24.7g / L; CuSO 4·5H 2 O2.5g / L; MnCl 2 4H 2 O 15.8g / L), the culture of G01, G02, G03 and 2369 needs to add 100 μg / mL of ampicillin and 34 μg / mL of chloramphenicol, and only 34 μg / mL of chloramphenicol is added for the culture of G04 strain. The addition of carbon sources glucose and glycerol in the fermentation medium was added according to the culture requirements with a mass volume co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com