Self-cutting undercut anchor

A bottom anchor, self-cutting technology, applied in the direction of connecting components, pins, mechanical equipment, etc., can solve problems such as large impact energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

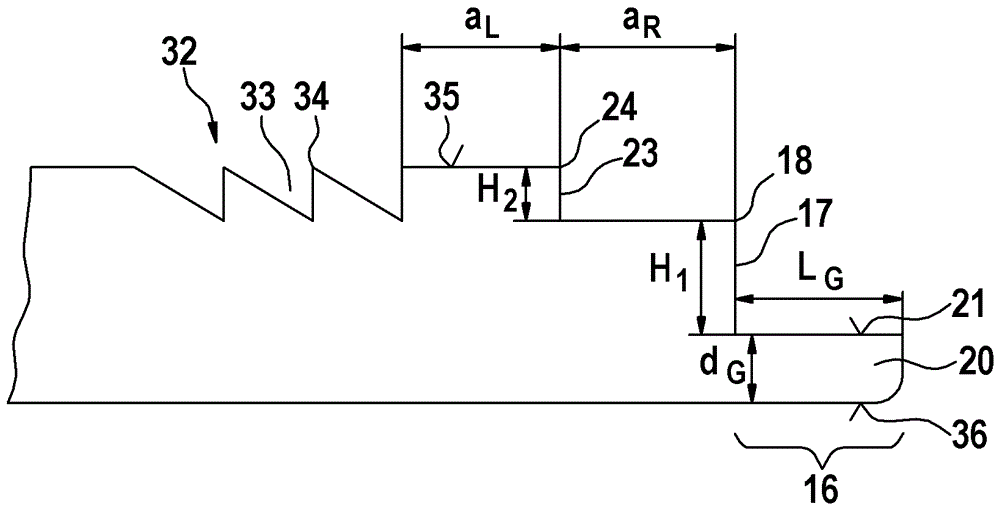

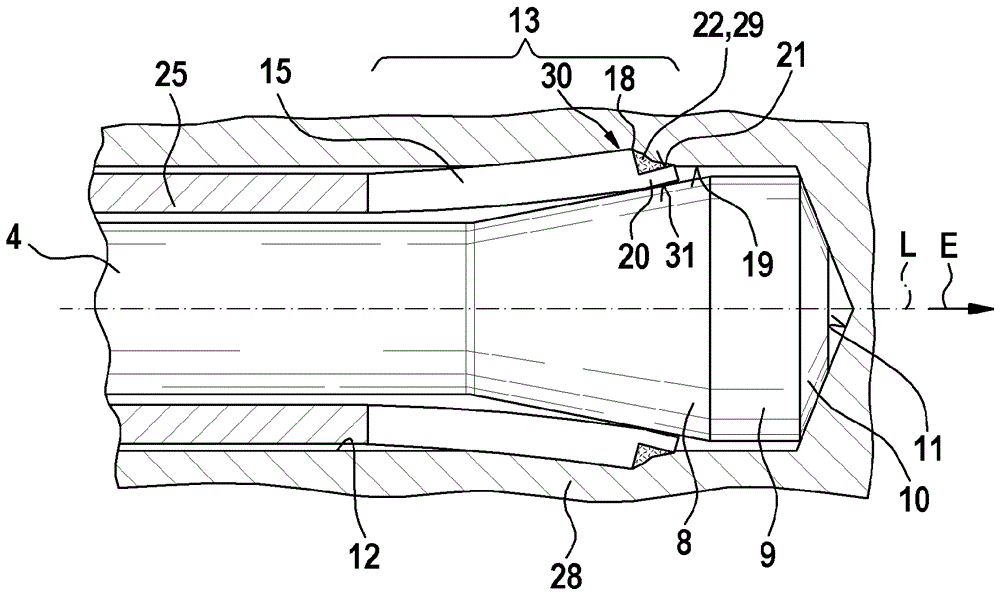

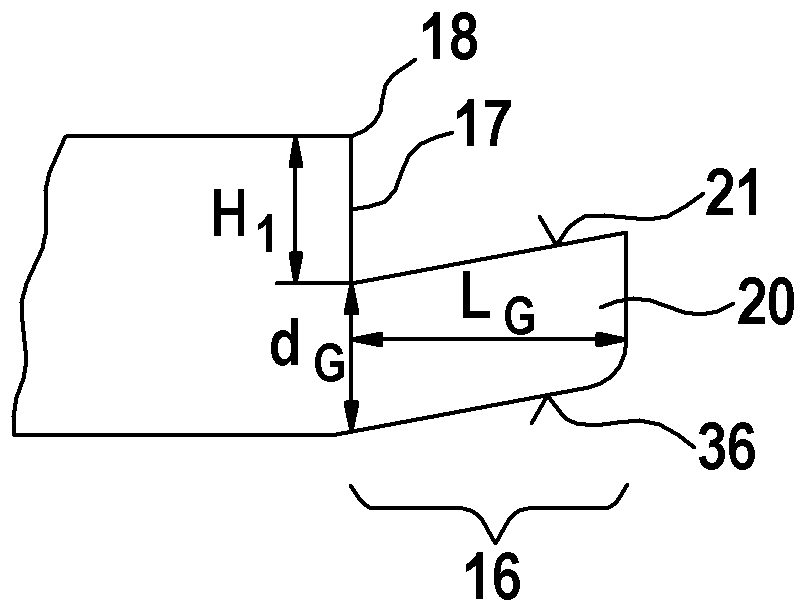

[0029] exist Figures 1 to 3a shows a first undercut anchor 1 according to the invention having an anchor 2 and an inflation sleeve 3 . The anchor 2 is made of steel and comprises an elongated cylindrical body 4 which extends along a longitudinal axis L which runs centrally in the body 4 and also forms the undercut anchor 1 and the expansion sleeve The longitudinal axis L of the barrel 3 . At the rear part of the body 4 in the insertion direction E, an external thread 5 is arranged as a load application device 6 which extends from the rear end of the anchor 2 in the insertion direction E through approximately the anchor 2 / 3 of the length of 2 and can be fastened at a mounting part (not shown) by means of nuts (also not shown). Along the insertion direction E, a swelling body 7 is formed on the anchor 2 . The inflation body 7 has a frusto-conical, conical inflation surface 8 which expands conically in diameter along the insertion direction E. FIG. Along the insertion direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com