Multi-liquid hydrogen storage tank parallel-connection injection method for hydrogen-oxygen rocket tests

A technology for testing and storage tanks, which is applied in container filling methods, container discharge methods, gas/liquid distribution and storage, etc., and can solve problems such as fluctuations in filling flow, different storage volumes, and complex liquid hydrogen filling processes. To achieve the effect of eliminating fluctuation shocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

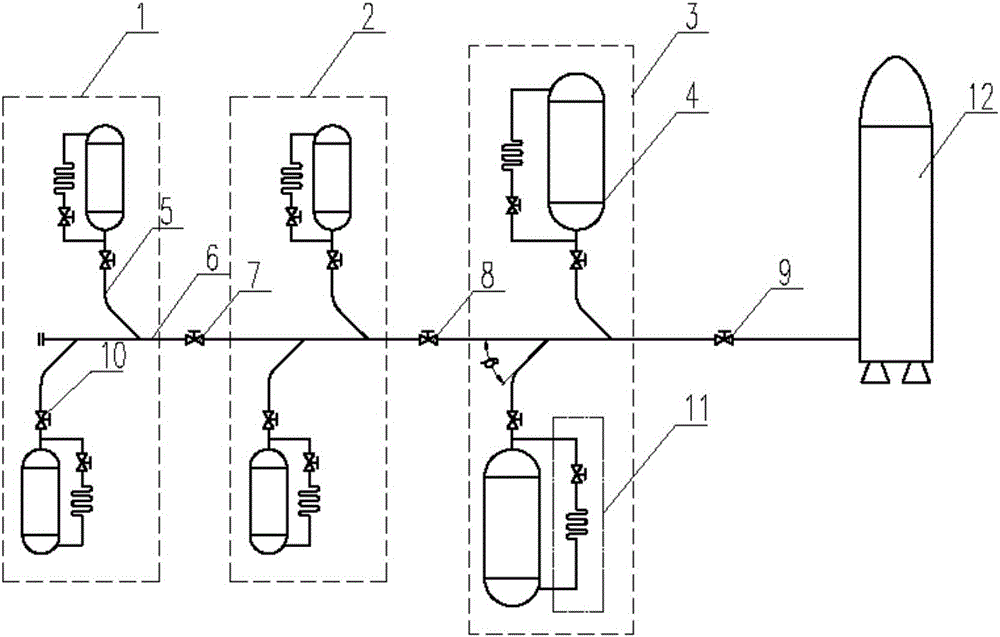

[0009] As shown in the accompanying drawings, the present invention consists of a precooling filling storage tank group 1, a small flow filling storage tank group 2, a large flow filling storage tank group 3, a liquid hydrogen storage tank 4, a branch pipeline 5, a main pipeline 6, It is composed of pre-cooling cut-off valve 7, small flow cut-off valve 8, total liquid outlet valve 9, liquid hydrogen storage tank filling and discharging valve 10, liquid hydrogen storage tank self-pressurization system 11 and other parts. First of all, when designing the branch pipeline and the main pipeline, the angle β between the branch pipeline and the main pipeline is considered, generally 30°~45°, which reduces the impact during the confluence process of the branch pipeline and is conducive to the stability of filling. Furthermore, according to the distan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com