Bypass hot wire plasma arc welding device and welding method

A technology of plasma welding and plasma arc, which is applied in the direction of plasma welding equipment, welding equipment, workpiece edge, etc., can solve the problems of limitation, limited penetration capacity, complicated installation and adjustment of welding equipment, etc., and achieves convenient operation and enhanced accessibility Good performance in property and droplet transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

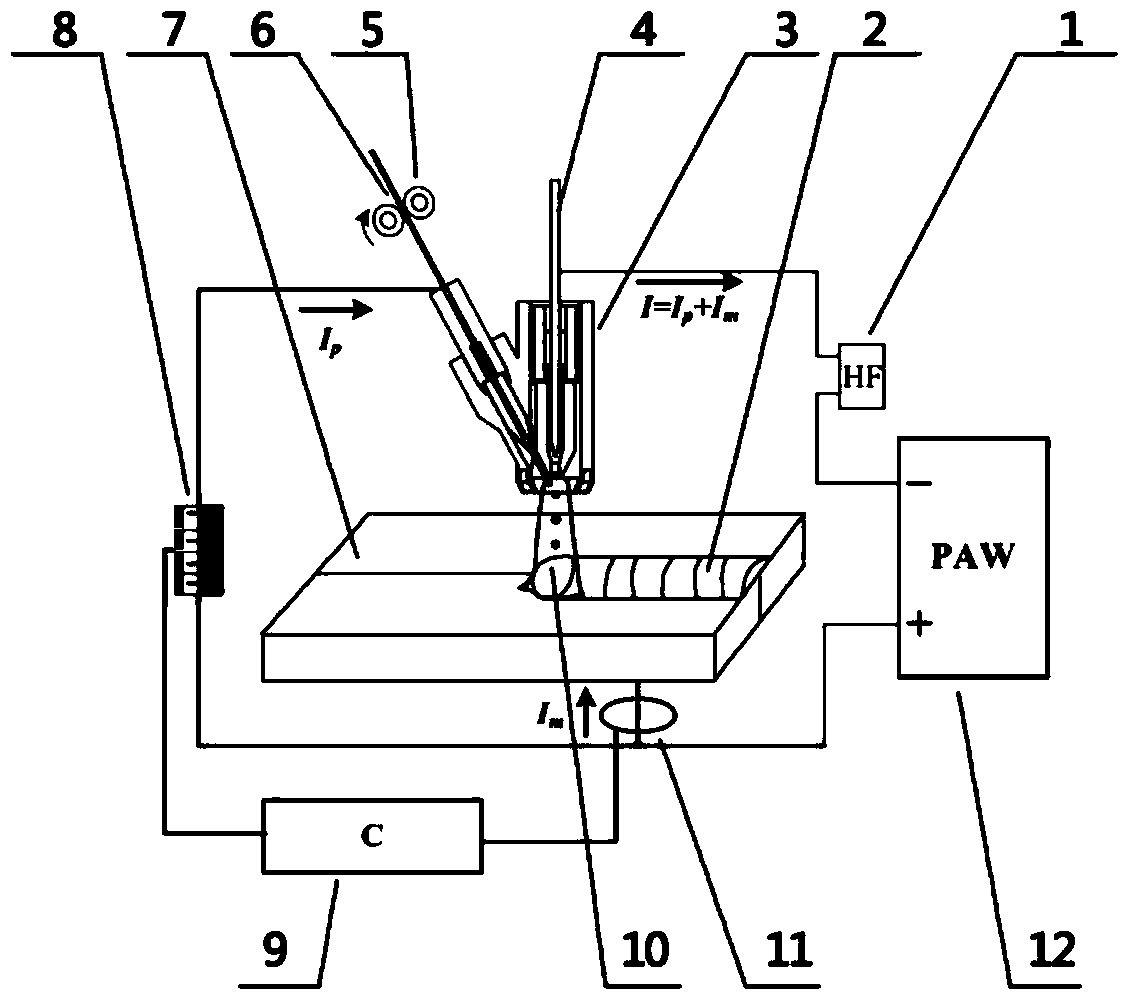

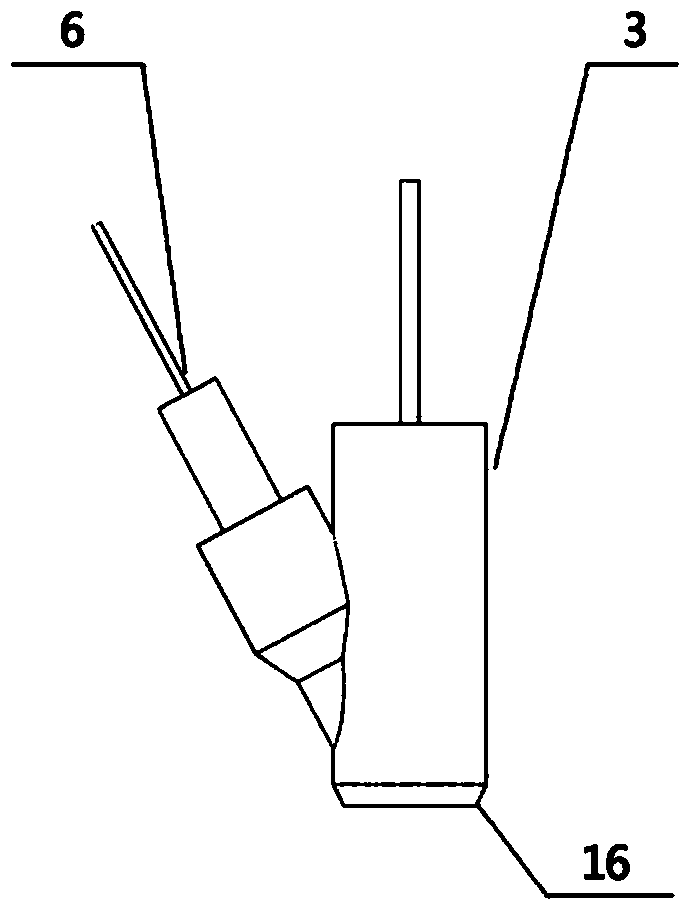

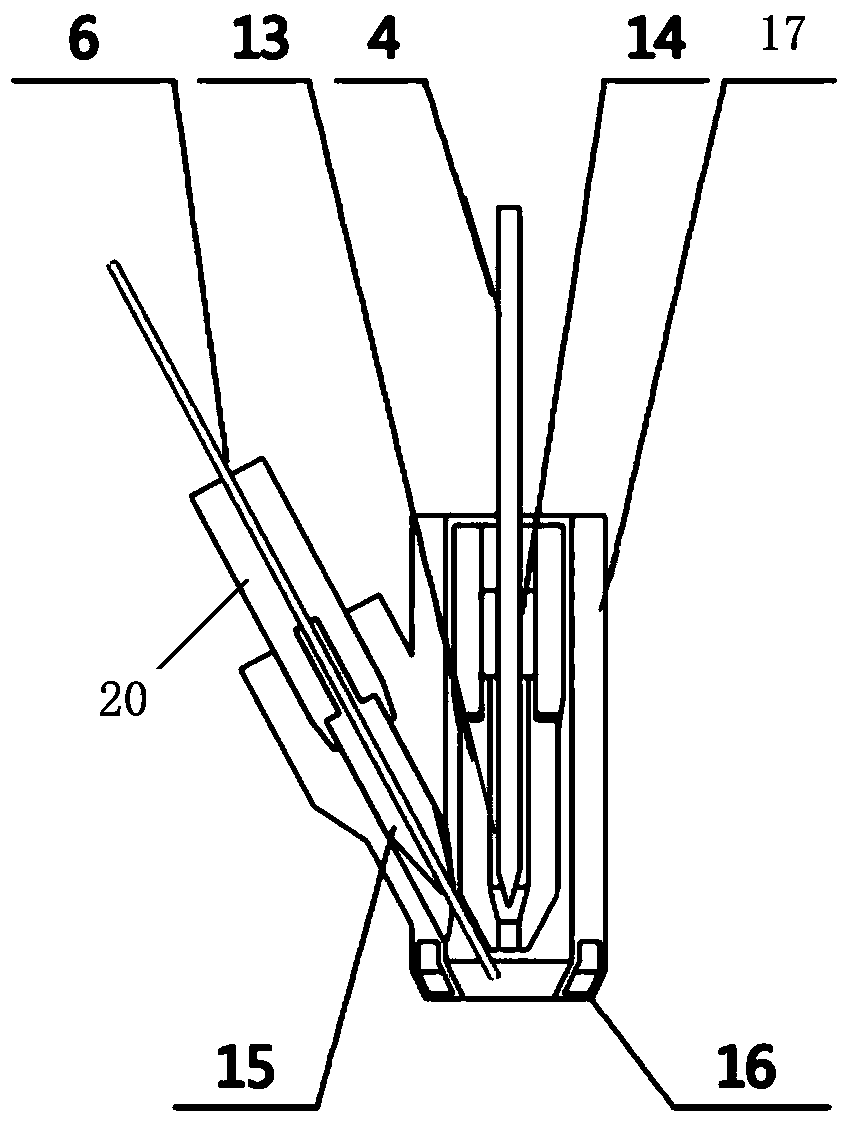

[0027] A bypass hot wire plasma arc welding device, combined with Figure 1 to Figure 4, the present invention is mainly composed of a plasma welding power source 12, an original design bypass hot wire plasma welding torch 3, a bypass shunt control module 8 and a current sensor 11 and the like. The bypass hot wire plasma torch 3 is the key component of the whole mechanism, mainly composed of the plasma tungsten electrode 4, the plasma torch nozzle 13, the bypass contact tip 15 and the welding wire 6, etc. The angle between the welding wire 6 and the tungsten electrode 4 is very small , between 15-30°, this specially designed wire feeding method can not only reduce the overall size of the welding torch, but also ensure that the welding wire is directly fed into the center of the coupling arc 10, improving the melting efficiency of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com