Novel electrolytic smelting furnace body temperature alarm device

An alarm device and technology for smelting furnaces, applied in the direction of furnaces, furnace components, lighting and heating equipment, etc., can solve problems such as leakage of electrolytic smelting furnaces, reduce staff, avoid leakage accidents, maximize safety and economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

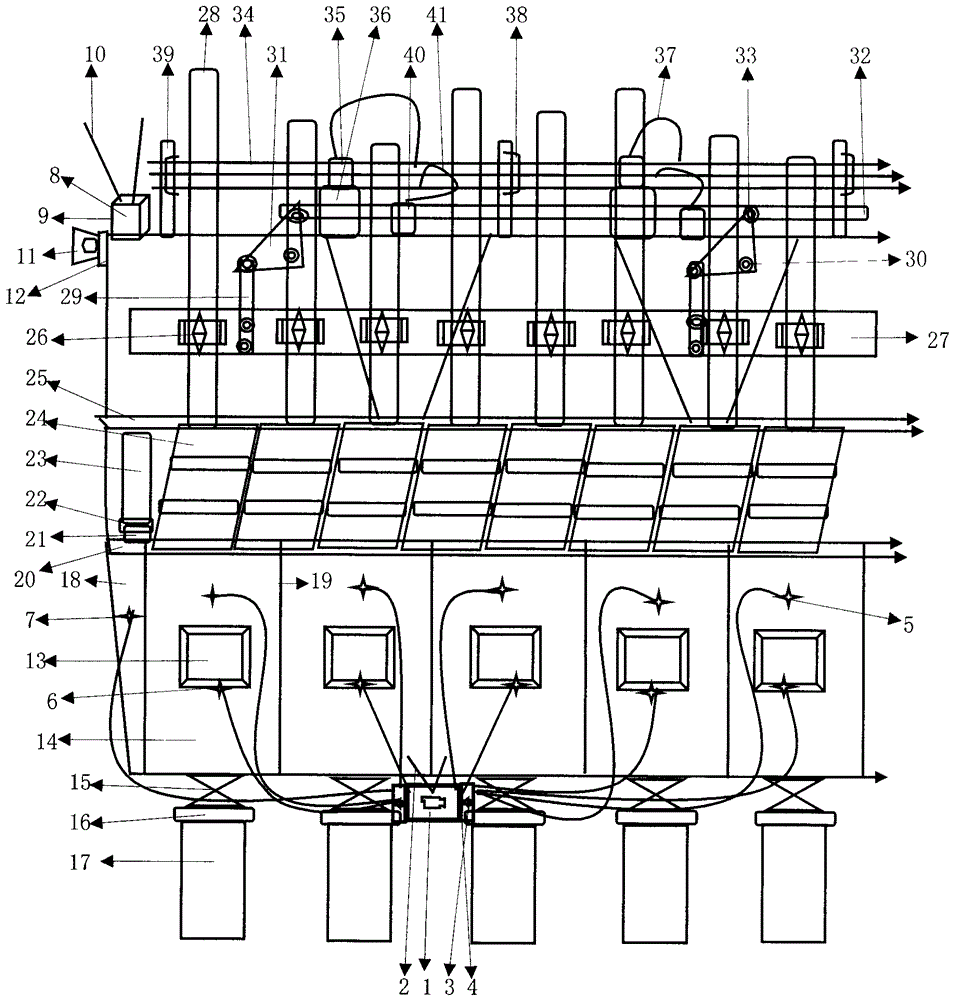

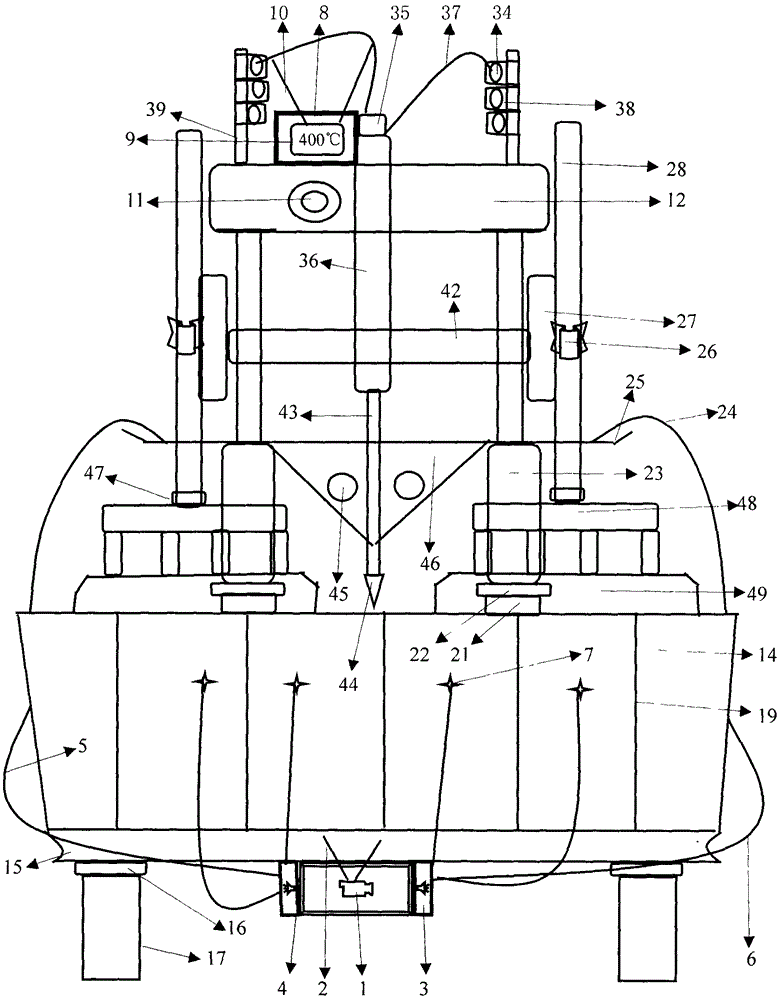

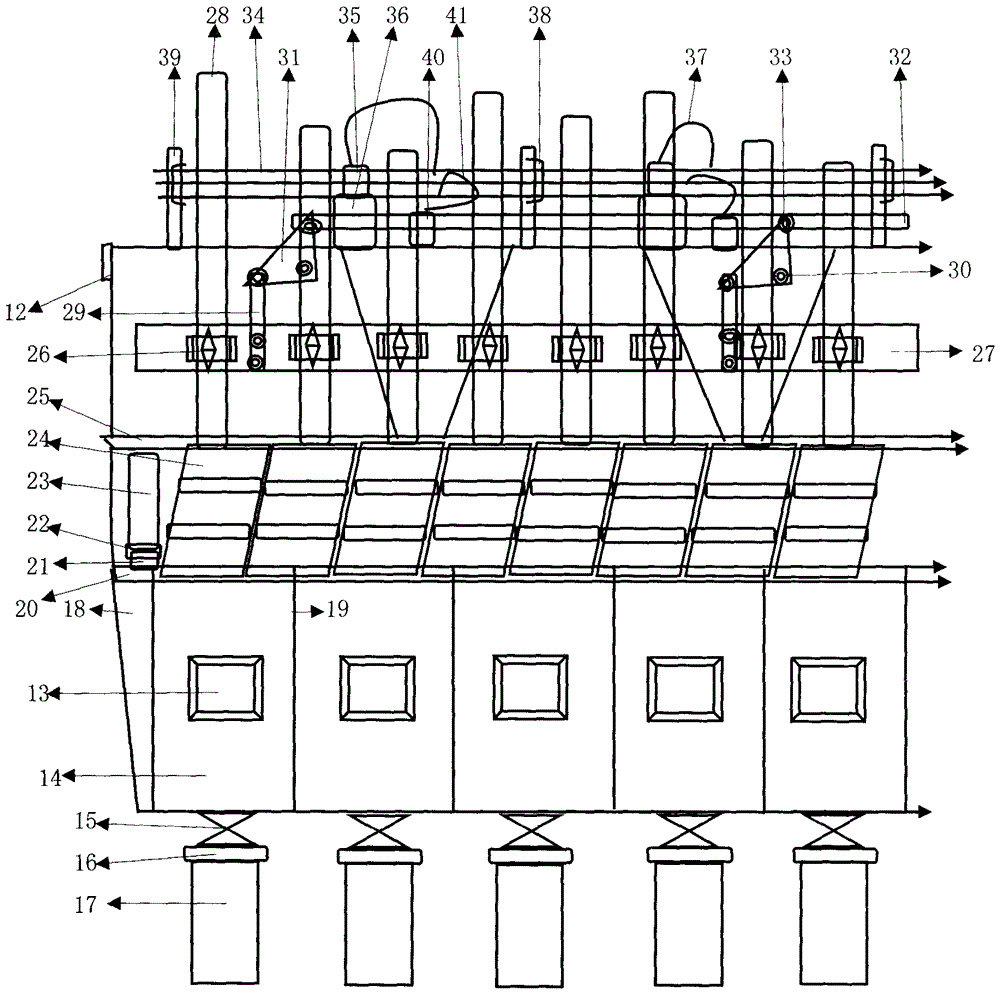

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited thereto.

[0016] like figure 1 As shown, a novel electrolytic smelting furnace body temperature alarm device of the present invention includes a temperature coding monitor 1 installed at the bottom of the electrolytic smelting furnace body, on which a signal transmitting antenna 2 and a wiring electronic row 3 and a fixed temperature The encoding monitoring machine framework 4, the electronic row 3 connects multiple electrolysis side furnace body temperature sensors 5, multiple cathode copper rod temperature sensors 6 and multiple electrolysis end furnace body temperature sensors 7 in sequence. The upper structure of the electrolytic smelting furnace is equipped with a temperature alarm receiver 8 with a digital and temperature display screen 9 and a temperature alarm receiving signal antenna 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com