Seal performance test device of airplane landing gear buffer

A technology for aircraft landing gear and sealing performance, which is applied in the use of liquid/vacuum for liquid tightness measurement, by detecting the appearance of fluid at the leak point, etc., which can solve the difficulty of hydraulic reciprocating sealing performance parameters, poor certainty, and difficult products. Quality assessment and other issues, to speed up the test and research progress, easy to operate, and moderately good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

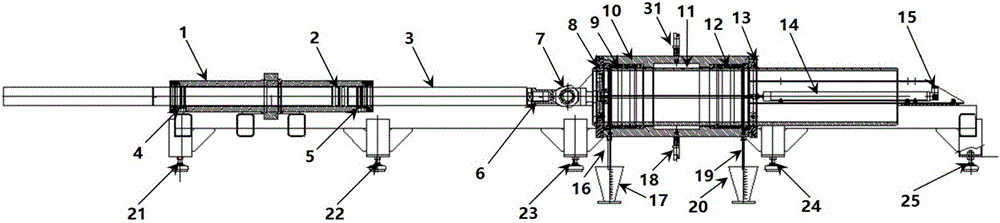

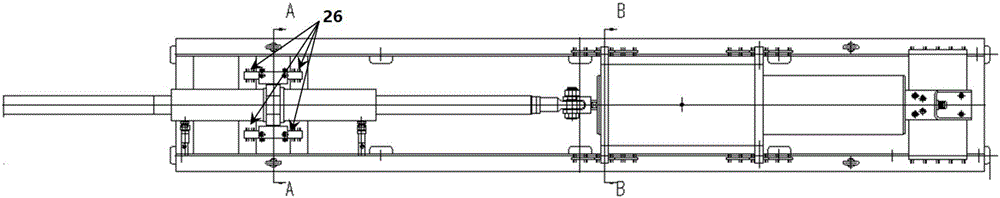

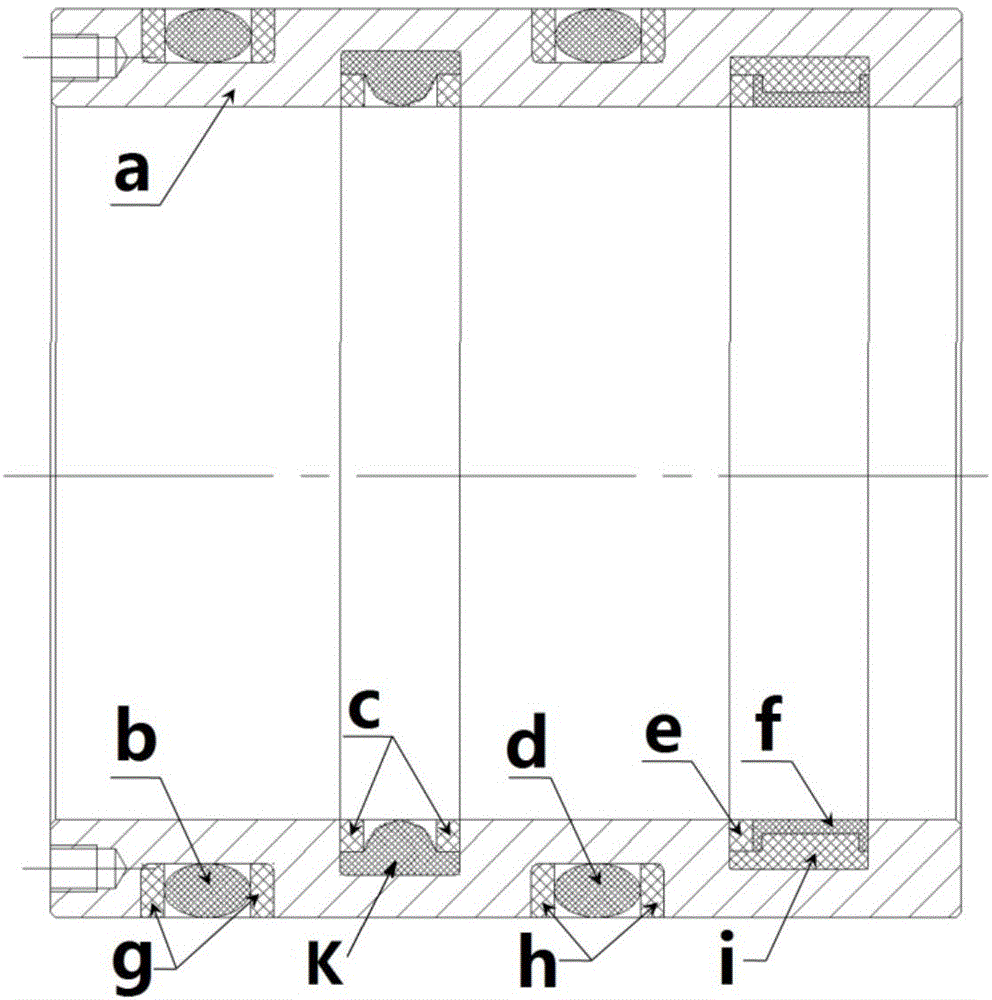

[0022] refer to Figure 1 to Figure 5 , Aircraft landing gear bumper sealing performance test device, comprises test stand iii, also includes servo cylinder 1 installed on the test stand iii, the piston rod 3 that reciprocates under hydraulic drive, test cylinder 10, actuator cylinder 11 and Detection mechanism 14, one end of described piston rod 3 passes through described servo cylinder 1, and the middle part of piston rod 3 located in servo cylinder 1 is provided with a cylindrical boss 2, and described cylindrical boss 2 will servo The inner cavity of the cylinder 1 is divided into a left cavity and a right cavity, and the ends of the left cavity and the right cavity are respectively provided with a first drive oil source inlet and outlet 4 and a second drive oil source inlet and outlet 5;

[0023] One end of the piston rod 3 is connected to the actuator 11 through a spherical joint 7, and the actuator 11 reciprocates with the piston rod 3; the outer side of the actuator 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com