Device for reducing growth of back of wafer

A backside and wafer technology, applied in gaseous chemical plating, coating, electrical components, etc., can solve problems affecting wafer leveling, affecting photoresist exposure defocus and OVL transformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

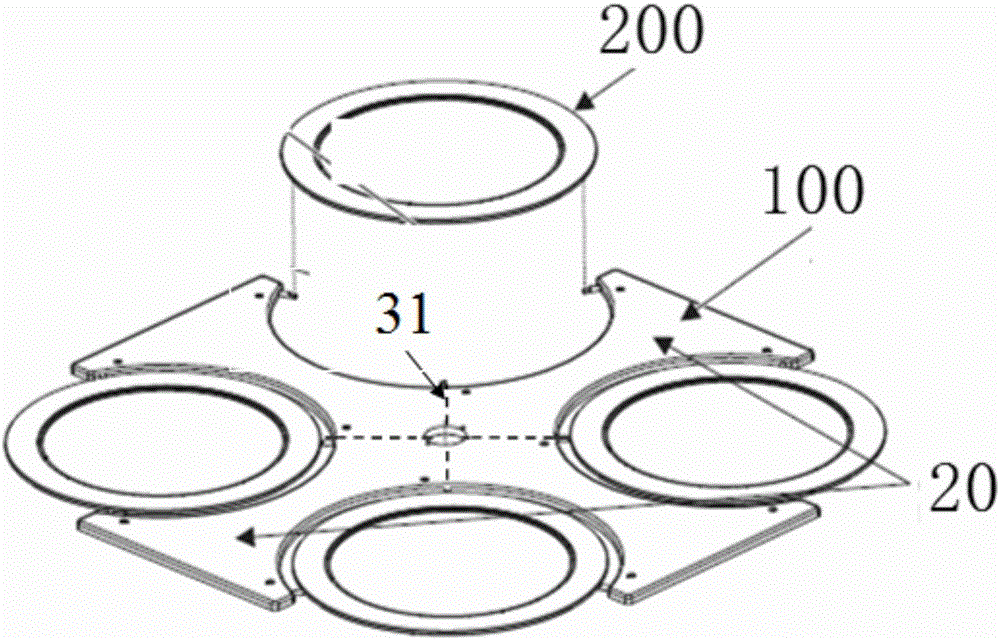

[0021] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

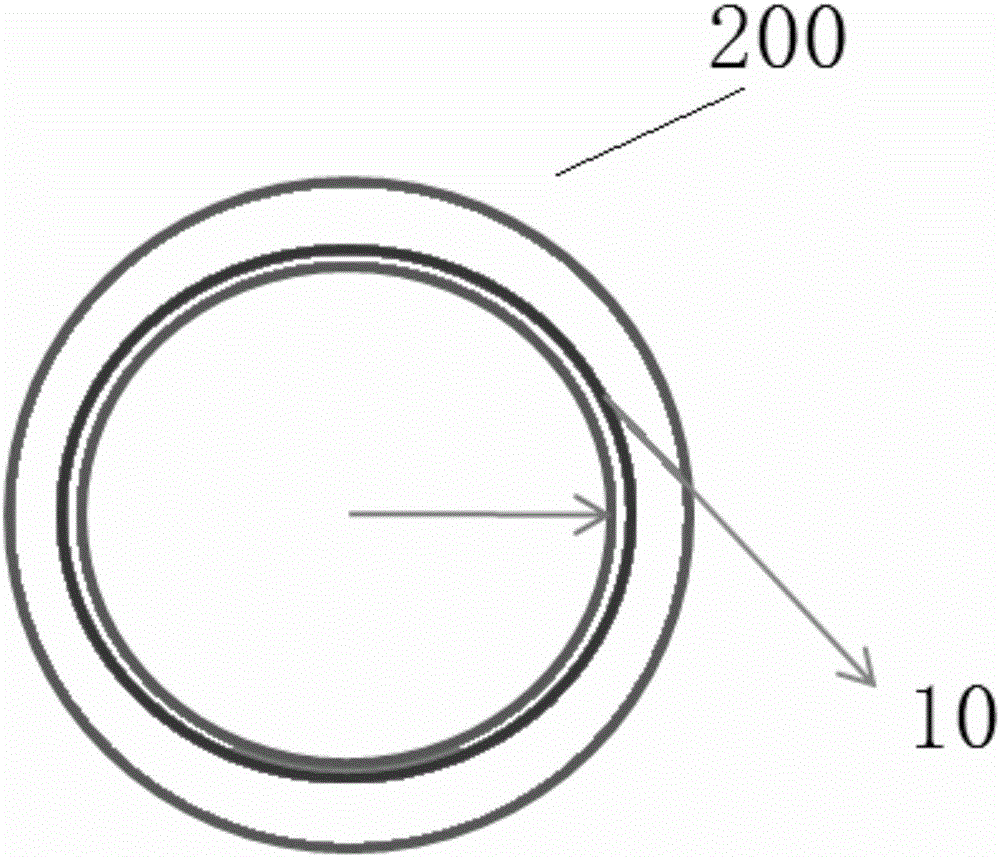

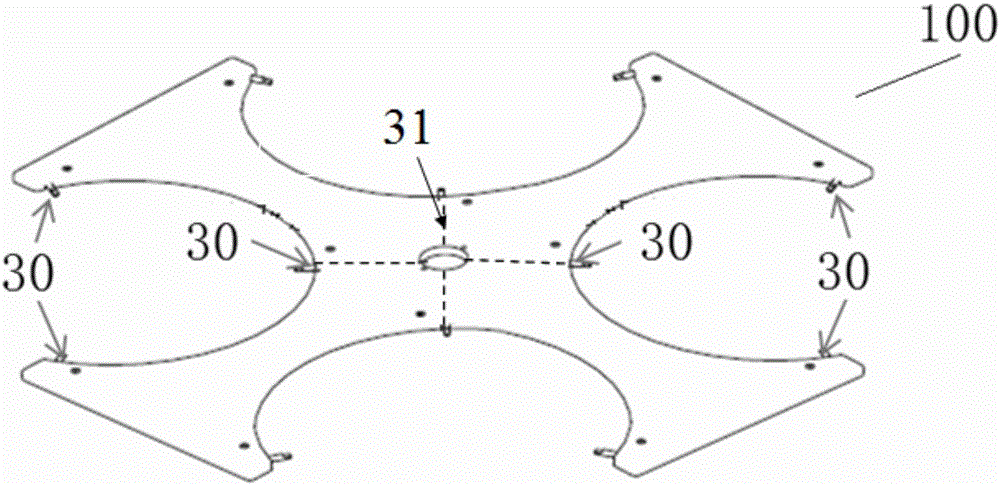

[0022] On the existing Novellus vector series machines, due to the defects in the machine design, the oxide grown by the atomic layer deposition method grows not only on the front side of the wafer, but also on the back side of the wafer. The growth of oxides brings many unnecessary problems to the follow-up. In view of this, the present invention can avoid the growth on the back side of the wafer by improving various structures. When the atomic layer precipitated oxide is grown under the device of the present invention, there will be no residue of the atomic layer precipitated oxide on the back of the wafer, so that the problems of defocus and OVL transformation in the photoresist exposure process of the subsequent process will not be affected....

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com