Electric vehicle leakage circuit, leakage method and electric vehicle

An electric vehicle and circuit technology, applied in electric vehicle charging technology, electric vehicles, battery circuit devices, etc., can solve the problems of heater, battery motor overheating, and high battery temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

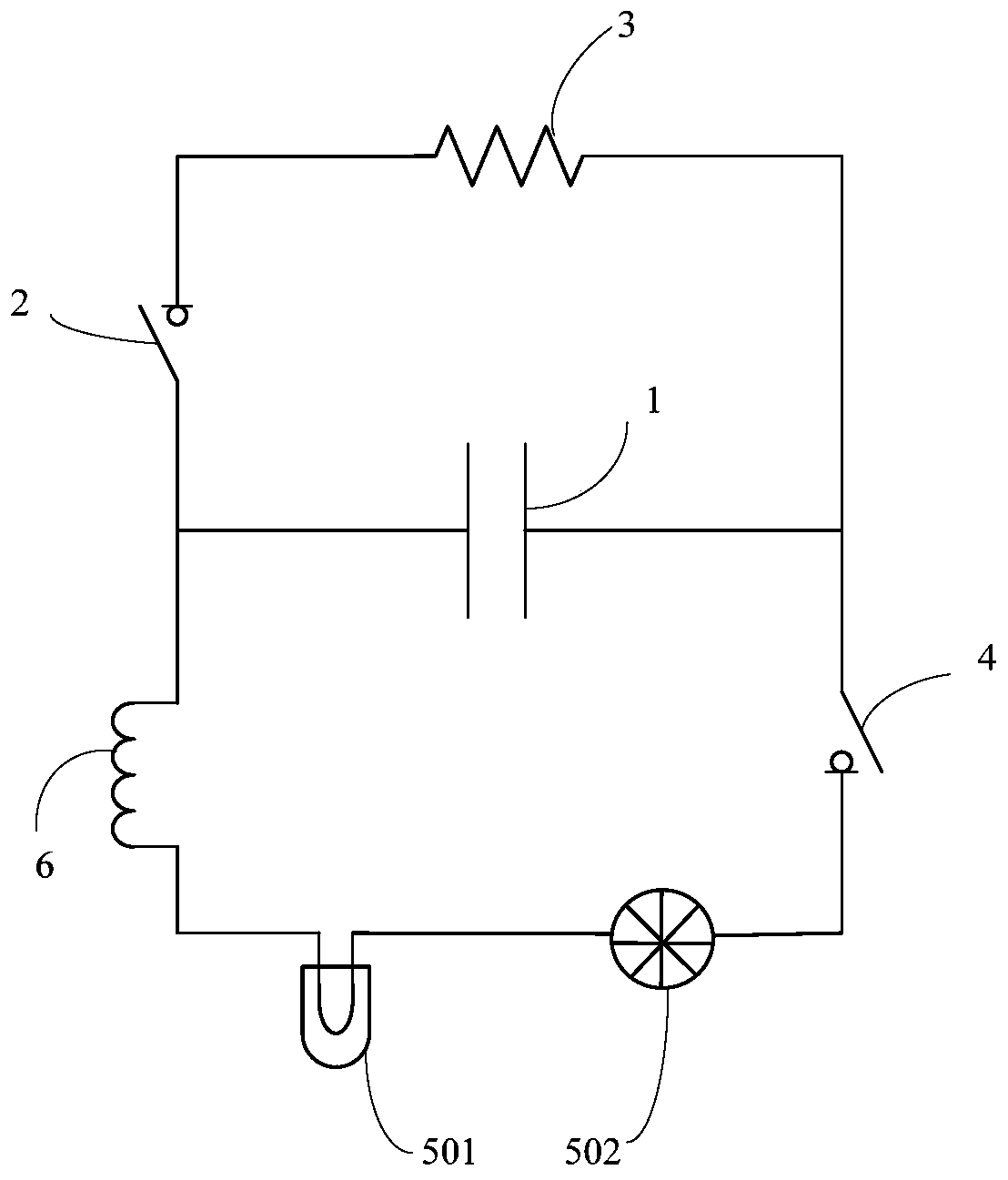

[0027] Embodiments of the present invention provide a leakage circuit of an electric vehicle, such as figure 1 shown, including:

[0028] A first leakage circuit and a second leakage circuit connected in parallel with the target leakage capacitor 1 of the electric vehicle, the first leakage circuit includes a first switch 2 connected in series and a heating resistor 3 of a heater of the electric vehicle , the second leakage circuit includes a second switch 4 and a power consumption device connected in series;

[0029] A controller for controlling on and off of the first switch 2 and the second switch 4, both of the first switch 2 and the second switch 4 are electrically connected to the controller.

[0030] Wherein, the target leakage capacitor 1 is a capacitor in the motor controller. When the electric vehicle is stopped, for safety reasons, it is necessary to unload the electricity stored in the target leakage capacitor 1 . However, in the embodiment of the present invent...

no. 2 example

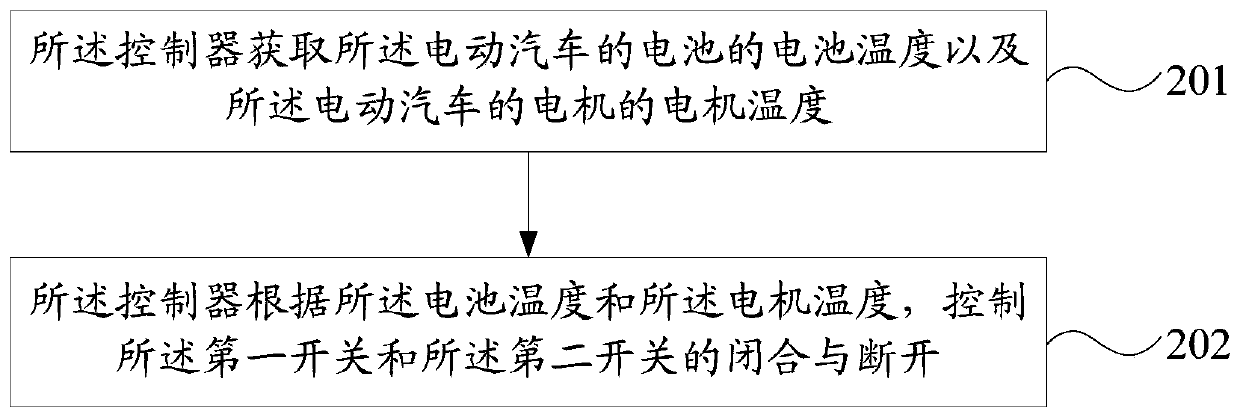

[0042] Embodiments of the present invention provide a leakage method for an electric vehicle, which is applied to the leakage circuit of the above-mentioned electric vehicle, such as figure 2 As shown, the method includes:

[0043] Step 201: The controller obtains the battery temperature of the battery of the electric vehicle and the motor temperature of the electric motor of the electric vehicle.

[0044]In the prior art, when the electric vehicle is stopped, the electric quantity of the target leakage capacitor is directly delivered to the heater or the motor to make it run for a period of time. However, when the temperature of the battery or the motor is high, the power of the target leakage capacitor is still delivered to the heater or the motor, which will cause the risk of overheating of the battery or the motor. However, in the embodiment of the present invention, the controller obtains the battery temperature of the battery and the motor temperature of the motor, so ...

no. 3 example

[0051] An embodiment of the present invention provides an electric vehicle, including the above electric vehicle leakage circuit. Therefore, the electric vehicle in the embodiment of the present invention can effectively avoid the risk of overheating of the heater, battery or motor through the cooperation of the first leakage circuit and the second leakage circuit when discharging the target leakage capacitor. , thereby prolonging the service life of electric vehicles and enhancing the market competitiveness of products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com